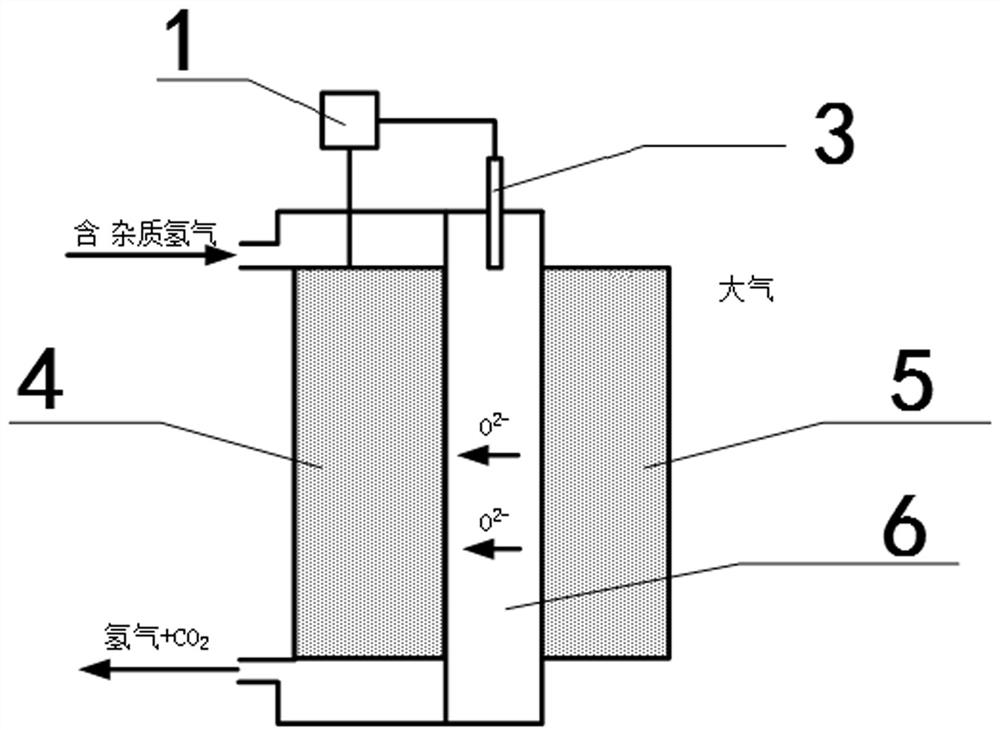

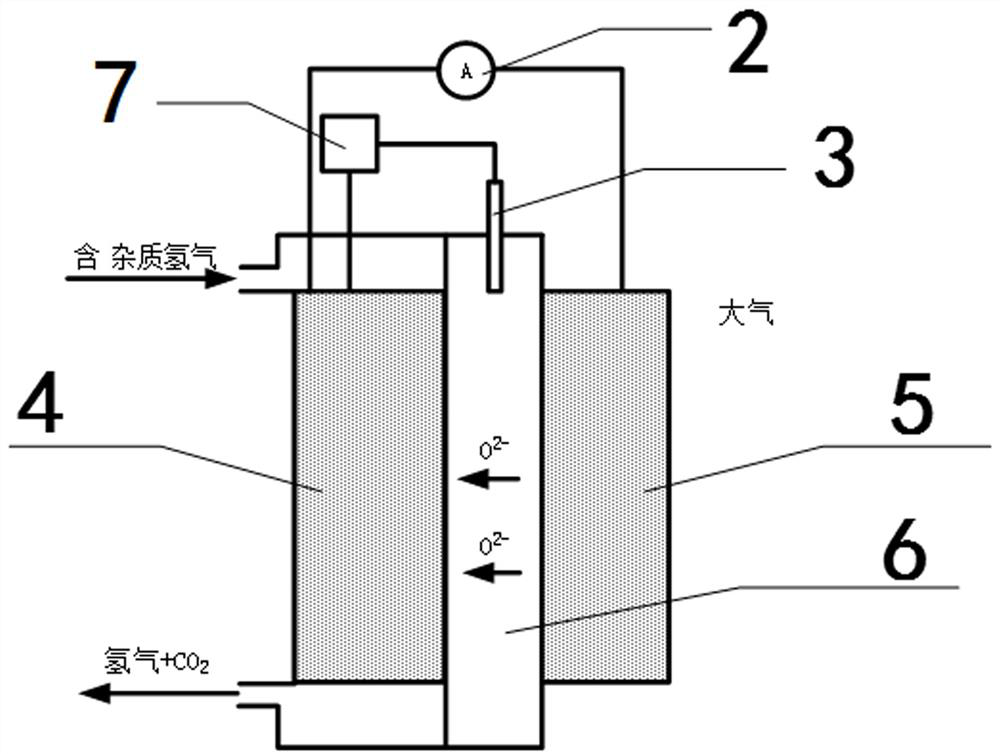

A hydrogen impurity purification device for fuel cells

A purification device and fuel cell technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of large occupied area, complex equipment, limited use, etc., achieve simple device, low complexity, and prevent potential The effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

[0070] The pressure reducing valve is set at the front end of the hydrogen gas inlet to be purified in the solid-state electrochemical reactor.

[0071] Preferably, the controller also includes an impurity concentration monitoring module. Wherein, the impurity concentration monitoring module further includes electric

[0074] Preferably, the impurity concentration monitoring module further includes an impurity concentration sensor. Among them, the impurity concentration sensor is installed in the solid

[0076] The principle of the device is described below.

[0079] Cathode: 0

[0083] Cathode: 2O

[0086] Anode: 2NO

[0087] Cathode: 2XO

[0095] 5. A heating device is integrated inside to maintain the conductivity of the ionic electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com