Graphene temperature sensor and preparing process thereof

A technology of temperature sensor and preparation process, which is applied in thermometers, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc., can solve the problems of not utilizing the properties of two-dimensional graphene and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

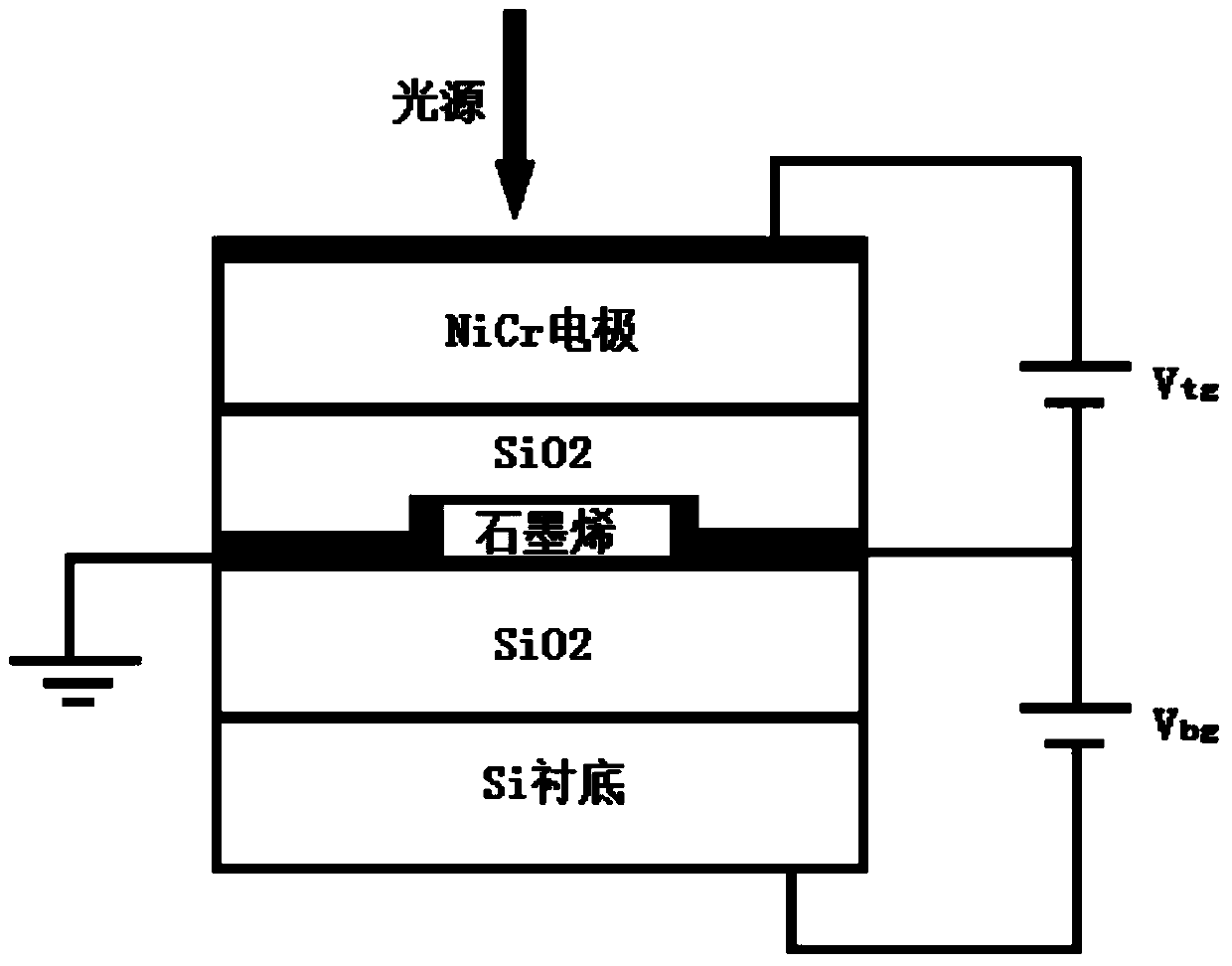

[0021] Embodiment: making graphene temperature sensor

[0022] When making the graphene temperature sensor, the present invention takes the following technical solutions:

[0023] 1. Preparation of SiO 2 / Si substrate: 300nm SiO is grown on Si substrate by dry oxidation process 2 film.

[0024] 2. Preparation of double-layer graphene: The method of mechanically exfoliating natural graphite is used to obtain double-layer graphene.

[0025] 3. Deposit double-layer graphene: deposit double-layer graphene on SiO 2 layer.

[0026] 4. Making source-drain electrodes: Make electrodes at the source-drain regions at both ends of the double-layer graphene. The method is to first make through holes by electron beam lithography, and then thermally evaporate 5nmCr and 100nmAu as electrodes.

[0027] 5. Deposition of silsesquioxane (HSQ): In order to protect graphene from being damaged in the SiO2 preparation process, a layer of 50nm thick silsesquioxane (HSQ) is first spin-coated, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com