Method for improving corrosion resistance of nickel-aluminum bronze

A nickel-aluminum bronze, corrosion-resistant technology, applied in the field of surface treatment, can solve the problems of many cracks on the surface of the coating, low Cr content in the coating, restricting the application of the coating, etc., and achieve the effect of low porosity, uniform composition and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example relates to a method for improving the corrosion resistance of nickel-aluminum bronze, said method may further comprise the steps:

[0038] Step 1: Mechanically polish the surface of nickel-aluminum bronze with 180#-400#-800#-1200# water sandpaper in sequence, and then degrease in the prepared degreasing solution (containing 20g / LNaOH, 30g / LNa 2 CO 3 , 50g / LNa 3 PO 4 ) at 70°C for 10 minutes, remove residual grease, wash with water, then use 100mL / L HCl to activate it, and dry it with cold air for later use;

[0039] Step 2: Put the treated nickel-aluminum bronze in the following plating solution:

[0040]

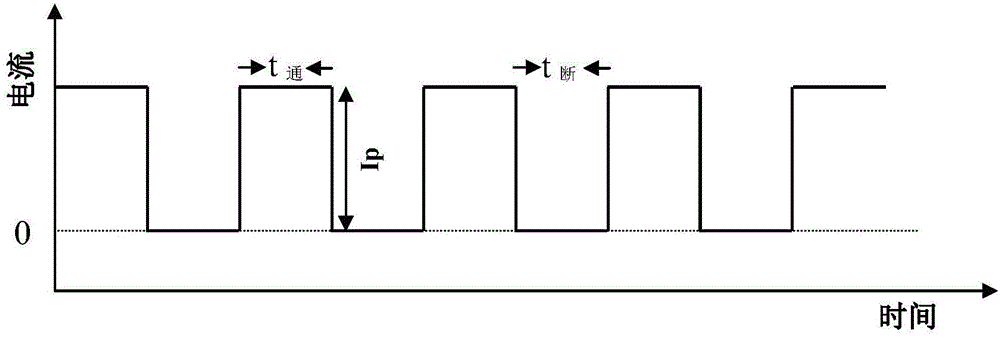

[0041] Heat the electrolyte temperature to 30-35°C; adjust its pH value to 2.2-2.7 with NaOH and HCl solution; the applied current waveform is shown in figure 1 As shown, the pulse current I p 10~15A / dm 2 , the pulse frequency is 1000Hz, the power-on time t 通 0.90ms, power-off time t 断 0.10ms, that is, the duty cycle is 90%; the electroplating...

Embodiment 2

[0045] This example relates to a method for improving the corrosion resistance of nickel-aluminum bronze, said method may further comprise the steps:

[0046] Step 1: Mechanically polish the surface of nickel-aluminum bronze with 180#-400#-800#-1200# water sandpaper in sequence, and then degrease in the prepared degreasing solution (containing 30g / LNaOH, 40g / LNa 2 CO 3 , 20g / LNa 3 PO 4 ) at 80°C for 5 minutes, remove residual grease, wash with water, then use 100mL / L HCl to activate it, and dry it with cold air for later use;

[0047] Step 2: Put the treated nickel-aluminum bronze in the following plating solution:

[0048]

[0049] Heat the electrolyte temperature to 35-40°C; adjust its pH value to 2.5-3.5 with NaOH and HCl solution; the applied current waveform is shown in figure 1 As shown, the pulse current I p 15~20A / dm 2 , the pulse frequency is 10000Hz, the power-on time t 通 0.25ms, power-off time t 断 0.75ms, that is, the duty cycle is 25%; the electroplating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface vickers hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com