Dynamic electronic mask plate system used for preparing monolithic integration capacitive touch screen through collage method

A technology of integrating capacitance and touch screen, applied in the field of mask system, can solve the problems of angle deviation, hinder mass production of integrated capacitive touch screen, and failure of mass production of products, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

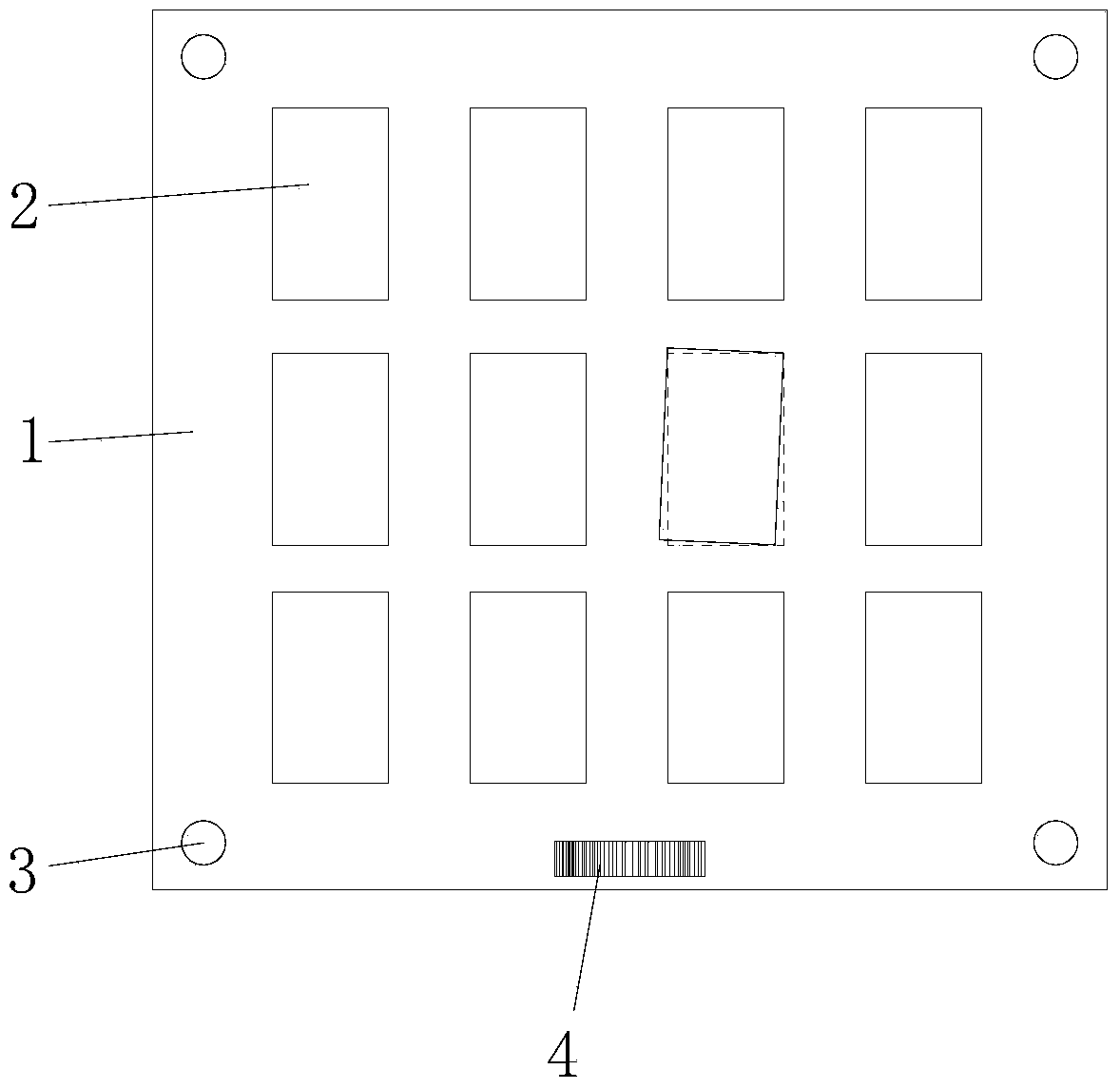

[0038] refer to figure 1 , a dynamic electronic mask system for preparing a monolithic integrated capacitive touch screen by a collage method. The process of preparing a monolithic integrated capacitive touch screen by the collage method is to first paste a small piece of glass on the carrier board, because the small piece of glass and the carrier board are physically separated It is separated, and the position of the small piece of glass will inevitably have a slight error (deviation). Therefore, it is necessary to calibrate the position of each small piece of glass and the position of the exposure pattern before exposure to ensure that the exposed optical path is imaged on each small piece. In the correct position of the glass, the system of the present invention includes:

[0039] Substrate carrying system: including the carrying plate 1 and the small pieces of glass 2 arranged on the carrying plate in a row, the arrangement of the carrying plate 1 and the small pieces of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com