A kind of non-woven fabric for mask base material and preparation method thereof

A non-woven fabric and base material technology, which is applied in the field of non-woven fabrics for mask base materials and its preparation, can solve the problems of whiteness and antibacterial properties without a clear solution, and achieve the best uniformity and comprehensive physical properties and antibacterial effect Good, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

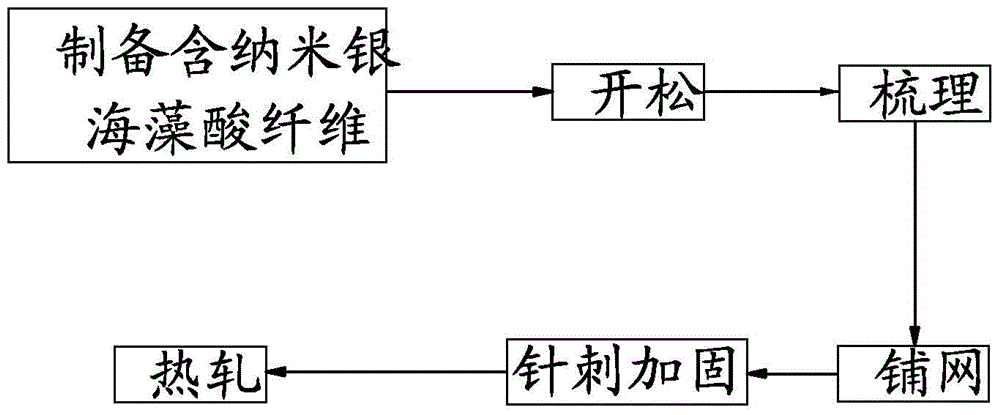

Method used

Image

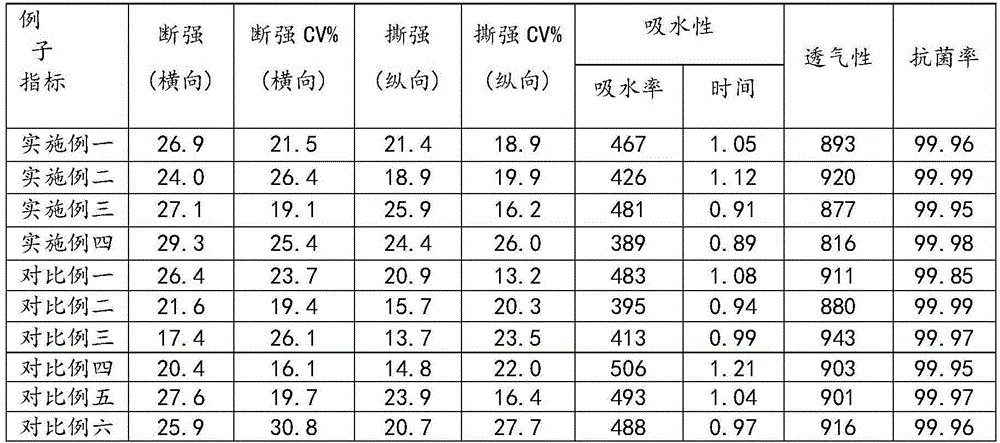

Examples

Embodiment 1

[0028] ①Preparation of nano-silver-containing alginic acid fiber: It is produced by blending and spinning sodium alginate and nano-silver-containing zirconium phosphate nano-compound, in which nano-silver ions are contained in the zirconium phosphate nano-particles;

[0029] ②Opening: Send the mixed fiber containing 60wt% nano-silver alginic acid fiber and 40wt% copper alginate fiber into the opening machine to make it fluffy to the greatest extent and mix them together evenly.

[0030] ③Carding: The mixture of nano-silver alginate fiber and copper alginate fiber that has been opened is fed into the carding machine through the cotton feeding system to be carded into a fiber web; during this process, the indoor temperature is controlled at 18-23°C, and the relative humidity Control at 60-90%, the main cylinder frequency of the carding machine is controlled at 600-800r / min, and the feeding speed is controlled at 1-3m / min.

[0031] ④ Laying: Repeatedly overlap the carded fiber we...

Embodiment 2

[0035] ①Preparation of nano-silver-containing alginic acid fiber: It is produced by blending and spinning sodium alginate and nano-silver-containing zirconium phosphate nano-compound, in which nano-silver ions are contained in the zirconium phosphate nano-particles;

[0036] ②Opening: Send the mixed fiber containing 90wt% nano-silver alginic acid fiber and 10wt% copper alginate fiber into the opening machine to make it fluffy to the greatest extent and mix it evenly.

[0037] ③Carding: The mixture of nano-silver alginate fiber and copper alginate fiber that has been opened is fed into the carding machine through the cotton feeding system to be carded into a fiber web; during this process, the indoor temperature is controlled at 18-23°C, and the relative humidity Control at 60-90%, the main cylinder frequency of the carding machine is controlled at 600-800r / min, and the feeding speed is controlled at 1-3m / min.

[0038] ④ Laying: Repeatedly overlap the carded fiber web, and the ...

Embodiment 3

[0042] ①Preparation of nano-silver-containing alginic acid fiber: It is produced by blending and spinning sodium alginate and nano-silver-containing zirconium phosphate nano-compound, in which nano-silver ions are contained in the zirconium phosphate nano-particles;

[0043] ②Opening: Send the mixed fiber containing 60wt% nano-silver alginic acid fiber and 40wt% copper alginate fiber into the opening machine to make it fluffy to the greatest extent and mix them together evenly.

[0044] ③Carding: The mixture of nano-silver alginate fiber and copper alginate fiber that has been opened is fed into the carding machine through the cotton feeding system to be carded into a fiber web; during this process, the indoor temperature is controlled at 18-23°C, and the relative humidity Control at 60-90%, the main cylinder frequency of the carding machine is controlled at 600-800r / min, and the feeding speed is controlled at 1-3m / min.

[0045] ④ Laying: Repeatedly overlap the carded fiber we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com