Mulberry cell fiber and preparation method thereof

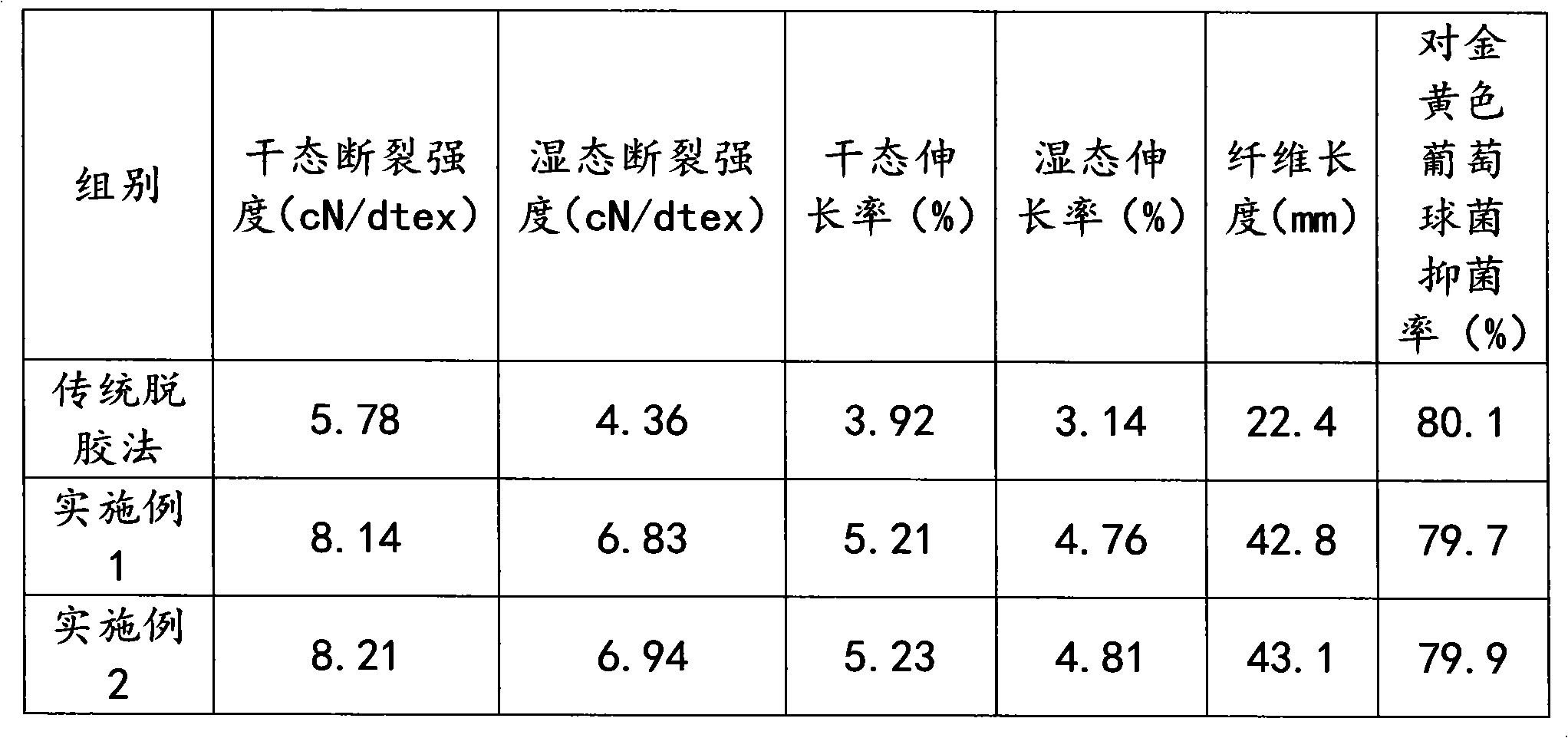

A fiber and bast fiber technology, applied in the field of regenerated fiber and its preparation, can solve the problems of low breaking strength, poor spinnability, complicated production process, etc., and achieves increased elongation at break, increased fiber length, and improved production rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) the mulberry bast fiber is re-cooked in a steamer, and the cooking condition adopts 20% of the mulberry bast fiber quality in terms of NaOH, the bath ratio is 1: 2, the heating time is 30 minutes, the cooking maximum temperature is 160 ℃, and it is incubated for 150 minutes. Let off the residual liquid after cooking, and beat it in a beater. After 90 minutes of beating time, remove impurities and fine fibers in a desander; bleach with a hydrogen peroxide bleaching tower, use hydrogen peroxide to measure mulberry bast 15% of fiber quality, bleaching temperature 50 ℃, bleaching time 30 minutes, make mulberry pulp.

[0023] 2) Put 20g of mulberry pulp in an impregnation barrel with an impregnating alkali concentration of 120g / L, and soak for 15 minutes at 85°C; press the impregnated mulberry pulp in a net chain press, and the pressing multiple 2.5 times; the pressed mulberry alkali cellulose is yellowed in a yellowing machine, and the yellowing agent is CS 2 , the conc...

Embodiment 2

[0026] 1) mulberry bast fiber is re-cooked in a cooker, and the cooking condition adopts 25% of the mulberry bast fiber quality in terms of NaOH, the bath ratio is 1: 4, the heating time is 45 minutes, the cooking maximum temperature is 180 ° C, and it is incubated for 200 minutes. Drain the residual liquid after cooking, and beat it in a beater. After 100 minutes of beating time, remove impurities and fine fibers in a desander; bleach with a hydrogen peroxide bleaching tower, use hydrogen peroxide to measure mulberry bast 20% of fiber quality, bleaching temperature 80 ℃, bleaching time 60 minutes, made mulberry pulp.

[0027] 2) Put 25g of mulberry pulp in an impregnation barrel with an impregnating alkali concentration of 150g / L, and soak for 30 minutes at 65°C; press the impregnated mulberry pulp in a net chain press, and the pressing multiple 3.5 times; the pressed mulberry alkali cellulose is yellowed in a yellowing machine, and the yellowing agent is CS 2 , the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com