Membrane oxide powder and preparation method and application thereof

An oxide powder, oxide technology, applied in chemical instruments and methods, graphite, semi-permeable membrane separation, etc., can solve the problems of poor hydrophilicity at the edge of graphene oxide, unfavorable water molecules passing, and cannot be applied to the field of water treatment, etc. To achieve the effect of easy industrialized large-scale production, mild and safe reaction conditions, and industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Step (1): Add 100 g of concentrated sulfuric acid to 1 g of 325 mesh natural graphite under ice-water bath conditions, and mix for 10 minutes;

[0053] Step (2): Add 1.5 g of potassium permanganate to the mixture obtained in step (1), heat to 35° C., and mix for 1.5 hours;

[0054] Step (3): in the mixture that step (2) obtains, drip into the deionized water of 200g dropwise, then drop into the hydrogen peroxide of 15g;

[0055] Step (4): washing the product obtained in step (3) repeatedly until the pH value is 7, and freeze-drying to obtain graphite oxide powder.

Embodiment 2

[0057] Step (1): Add 100 g of concentrated sulfuric acid to 1 g of 325 mesh natural graphite under ice-water bath conditions, and mix for 10 minutes;

[0058] Step (2): Add 1.65 g of potassium permanganate to the mixture obtained in step (1), heat to 35° C., and mix for 1 hour;

[0059] Step (3): in the mixture that step (2) obtains, drip into the deionized water of 200g dropwise, then drop into the hydrogen peroxide of 15g;

[0060] Step (4): washing the product repeatedly until the pH value is 7, and freeze-drying to obtain graphite oxide powder.

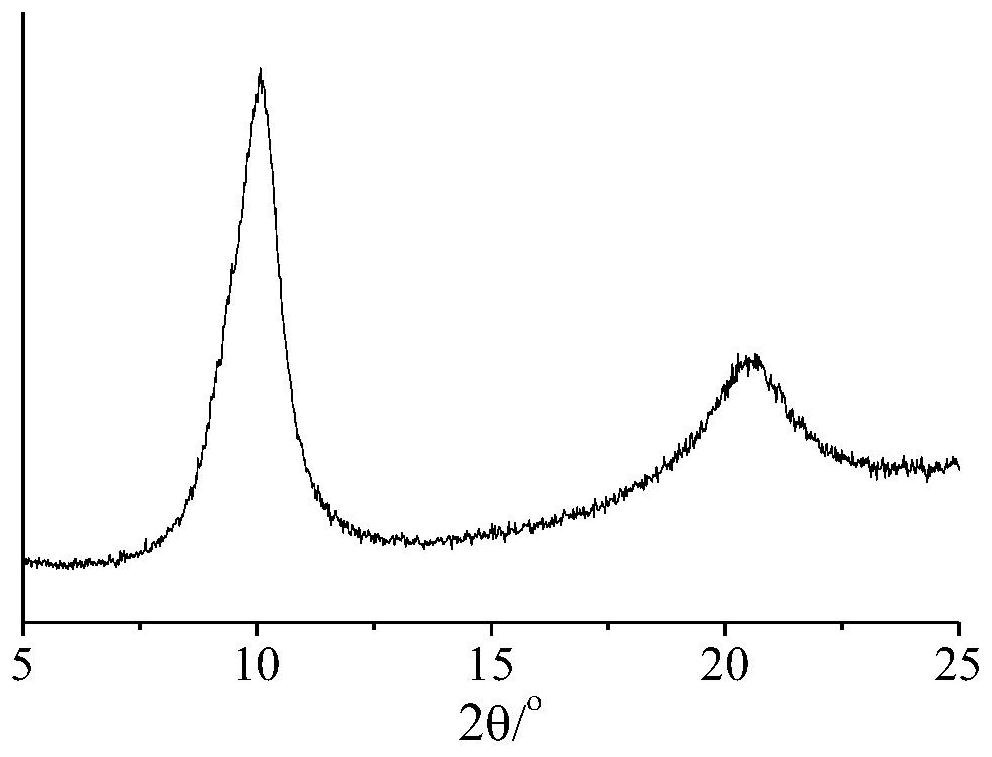

[0061] Since the oxidation degree of the graphite oxide is lower than that of the traditional graphite oxide, the XRD curve of the product not only has a diffraction peak around 2θ=10°, but also has a diffraction peak around 2θ=20° at the same time.

Embodiment 3

[0063] Step (1): Add 100 g of concentrated sulfuric acid to 1 g of 325 mesh natural graphite under ice-water bath conditions, and mix for 10 minutes;

[0064] Step (2): Add 1.65 g of potassium permanganate to the mixture obtained in step (1), heat to 35° C., and mix for 1.5 hours;

[0065] Step (3): in the mixture that step (2) obtains, drip into the deionized water of 200g dropwise, then drop into the hydrogen peroxide of 15g;

[0066] Step (4): washing the product repeatedly until the pH value is 7, and freeze-drying to obtain graphite oxide powder.

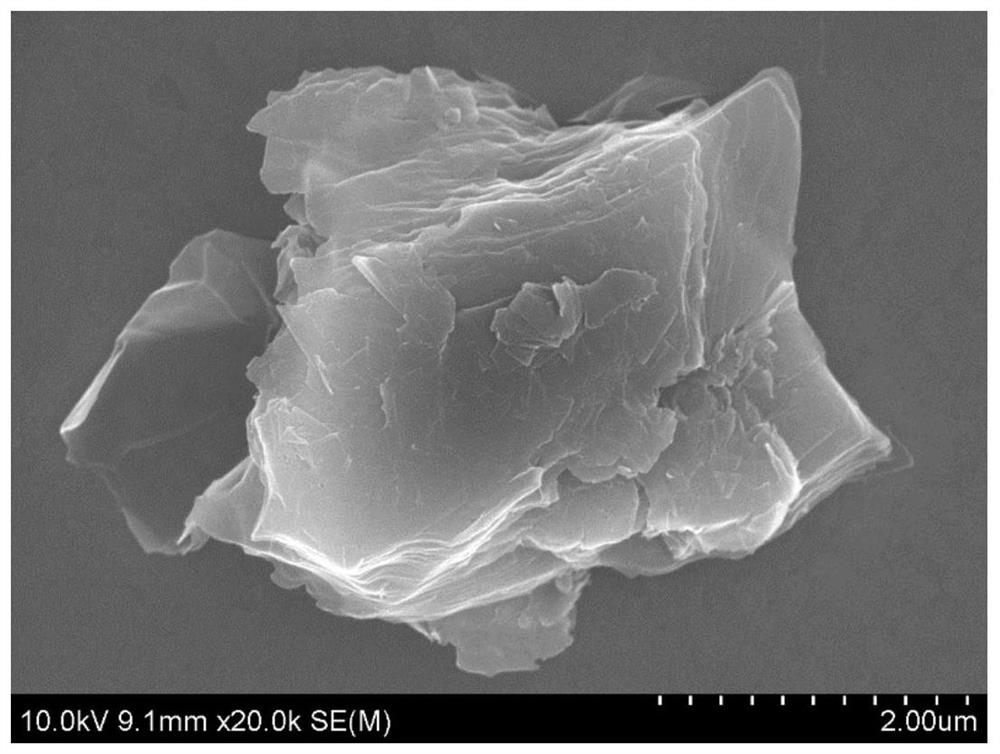

[0067] Electron micrographs show that graphite oxide maintains the morphology of natural graphite raw materials, and the edge is whiter than the center due to the high degree of oxidation and poor electrical conductivity.

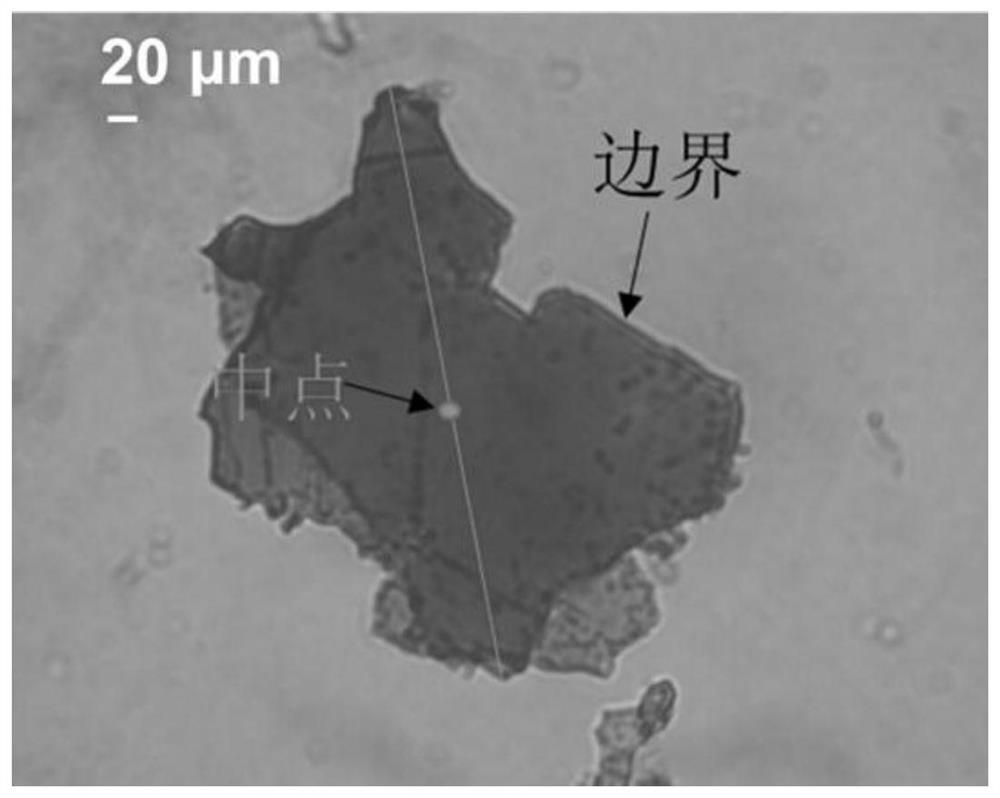

[0068] The optical microscope photos show that the graphite oxide is irregular in shape, and its maximum and minimum sheet diameters are relatively close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com