Three-dimensional oxidized graphene frame film and preparing method and application thereof

A graphene membrane and graphene technology, applied in the field of materials, can solve the problems of reduced separation performance, uncontrollable channels, and prone to defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

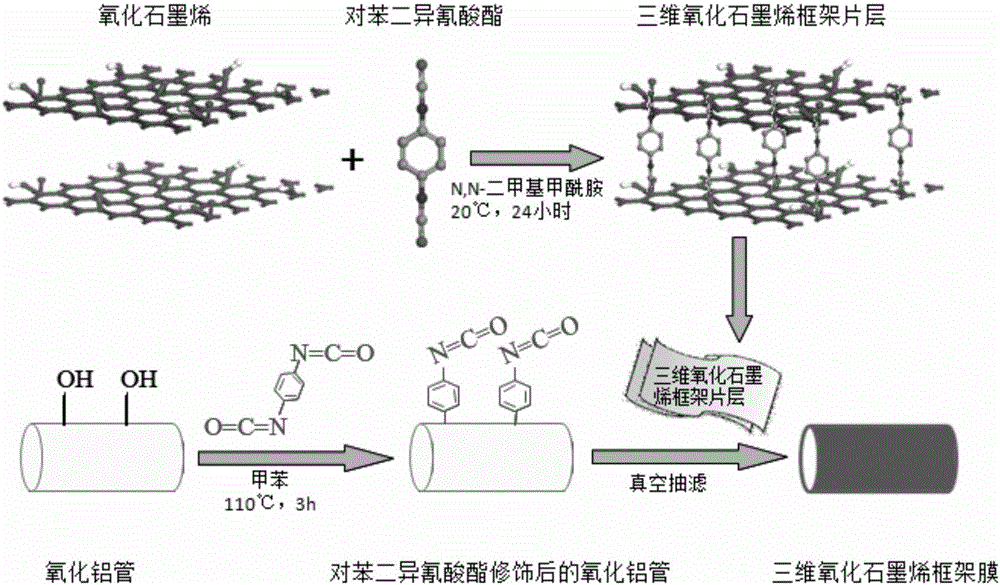

[0091] The present invention also provides a method for preparing the frame film, comprising the following steps:

[0092] i) providing PDI-modified graphene oxide and PDI-modified porous alumina tubular support; and

[0093] ii) loading the PDI-modified graphene oxide on the surface of the PDI-modified porous alumina tubular support by vacuum filtration to obtain the framework membrane.

[0094] In another preferred example, the vacuum filtration pressure in step ii) is 0.05-1 MPa.

[0095] In another preferred embodiment, after step ii), a step is further included: drying and curing the product obtained in the preceding steps at 20-40°C.

[0096] In another preferred example, the time for the drying and curing treatment is 1-48 hours, preferably 5-30 hours.

[0097] In the present invention, the graphene oxide modified by PDI is prepared as follows:

[0098] a-1) providing a first mixed solution, said first mixed solution comprising graphene oxide, PDI and a first solvent...

Embodiment 1 3

[0119] Embodiment 1 Three-dimensional graphene oxide frame film 1

[0120] Step 1. PDI functional modification of graphene oxide

[0121] Graphene oxide is modified with p-phenylene diisocyanate PDI to increase the interlayer distance, form covalent bonds between graphene oxide sheets, and connect graphene oxide sheets.

[0122] 40ml of the graphene oxide DMF dispersion with a concentration of 0.625mg / mL was mixed with 40ml of a DMF dispersion of PDI with a concentration of 0.025mg / mL, and stirred at room temperature for 24h to react.

[0123] Step 2: PDI functional modification of porous tubular alumina carrier

[0124] Put the porous alumina tubular support into 40ml of DMF emulsion dispersed with 1mmol of p-phenylene diisocyanate, and treat it at 110°C for 3h, so as to introduce -CNO organic functional group on the surface of the porous alumina tubular support (which is combined with the alumina support surface hydroxyl groups) to form a p-phenylene diisocyanate modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com