Non-woven fabric for facial mask base materials as well as preparation method thereof

A technology of non-woven fabrics and base materials, which is applied in the field of non-woven fabrics for mask base materials and its preparation, which can solve the problems of whiteness and antibacterial properties without a clear solution, achieve the best uniformity and comprehensive physical properties, and maintain appearance , the effect of good uniformity of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

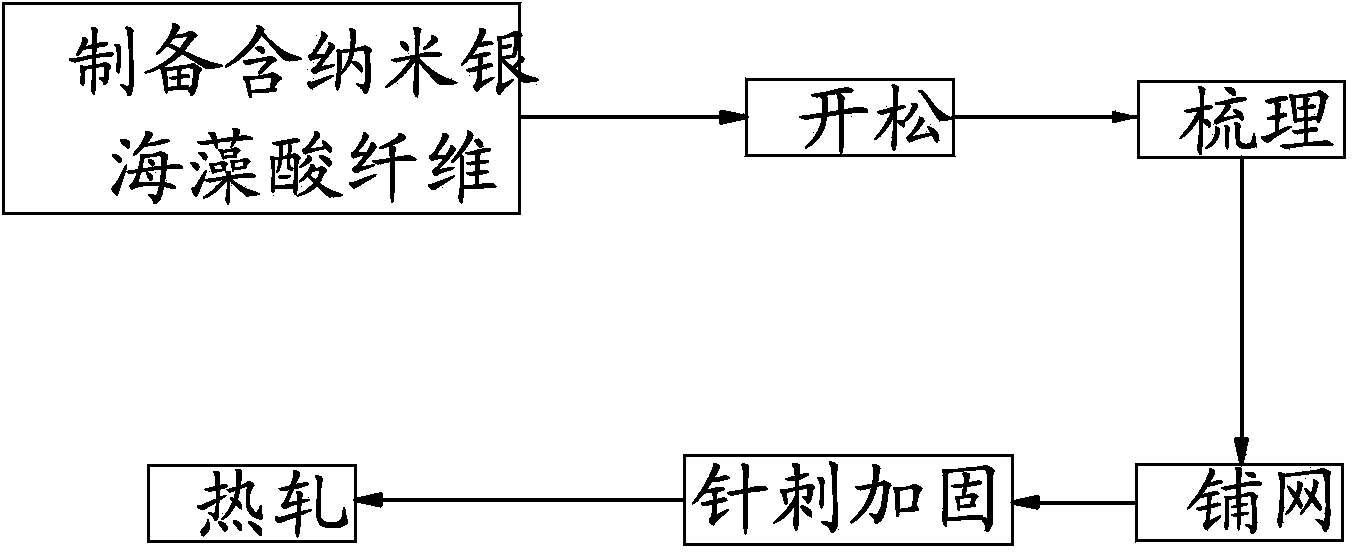

Method used

Image

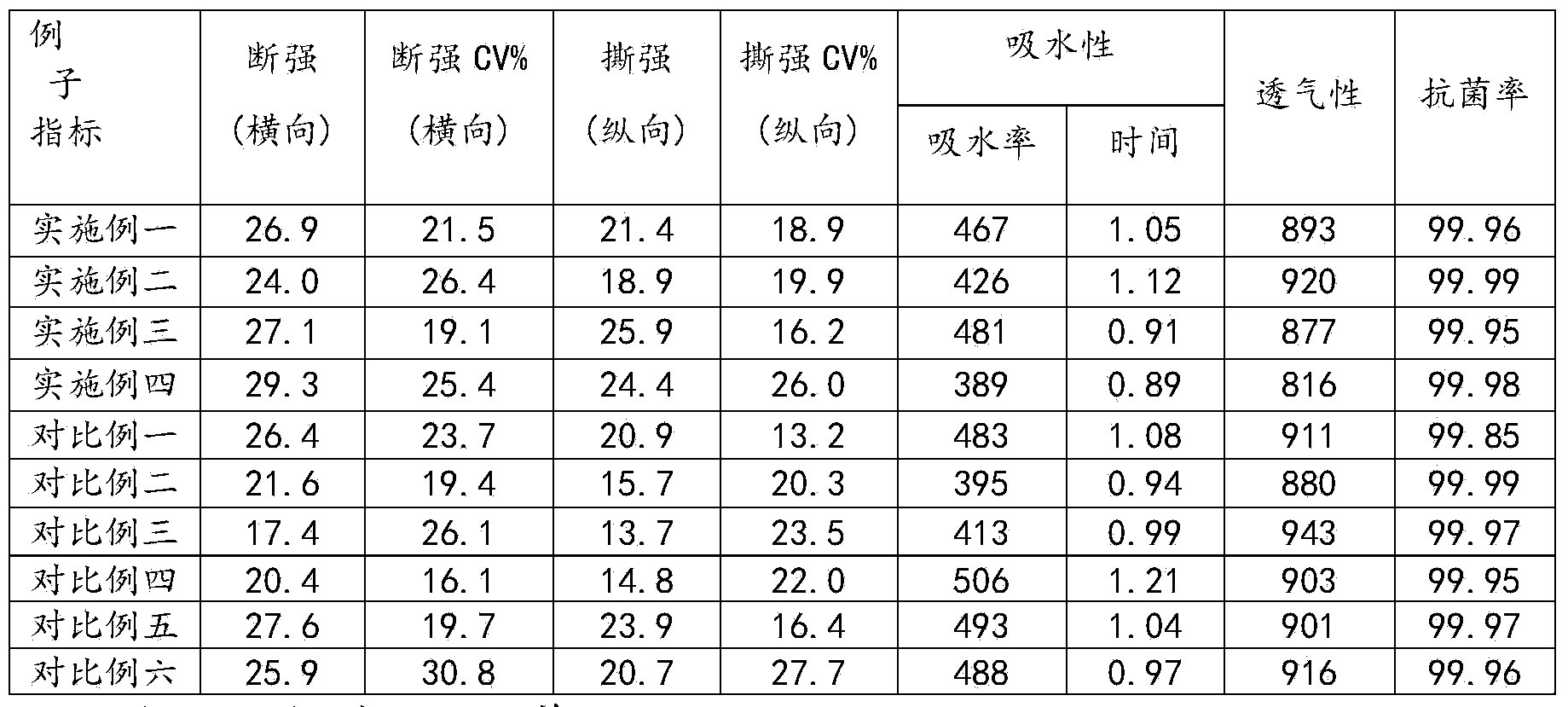

Examples

Embodiment 1

[0028] ①Preparation of nano-silver-containing alginate fiber: It is produced by blending and spinning sodium alginate and nano-silver-containing sodium zirconium phosphate compound, wherein the nano-silver ions are contained in the inner zirconium phosphate particles;

[0029] ②Opening: Send 60wt% of the mixed fiber containing nano silver alginate fiber and 40wt% of copper alginate fiber to the opener to maximize the fluffy state and mix them evenly.

[0030] ③Carding: the opened mixture containing nano-silver alginate fiber and copper alginate fiber is fed into a carding machine through a cotton feeding system to be carded into a fiber web; during this process, the indoor temperature is controlled at 18-23°C and relative humidity Control at 60-90%, the main cylinder frequency of the carding machine is controlled at 600-800r / min, and the feeding speed is controlled at 1-3m / min.

[0031] ④Laying the net: Repeatedly overlap the fiber net after carding, and the single net weight is 6g. ...

Embodiment 2

[0035] ①Preparation of nano-silver-containing alginate fiber: It is produced by blending and spinning sodium alginate and nano-silver-containing sodium zirconium phosphate compound, wherein the nano-silver ions are contained in the inner zirconium phosphate particles;

[0036] ②Opening: Send 90wt% of the mixed fiber containing nano silver alginate fiber and 10wt% of copper alginate fiber to the opener to maximize the fluffy state and mix them evenly.

[0037] ③Carding: the opened mixture containing nano-silver alginate fiber and copper alginate fiber is fed into a carding machine through a cotton feeding system to be carded into a fiber web; during this process, the indoor temperature is controlled at 18-23°C and relative humidity Control at 60-90%, the main cylinder frequency of the carding machine is controlled at 600-800r / min, and the feeding speed is controlled at 1-3m / min.

[0038] ④Laying the net: Repeatedly overlap the fiber net after carding, and the single net weight is 6g. ...

Embodiment 3

[0042] ①Preparation of nano-silver-containing alginate fiber: It is produced by blending and spinning sodium alginate and nano-silver-containing sodium zirconium phosphate compound, wherein the nano-silver ions are contained in the inner zirconium phosphate particles;

[0043] ②Opening: Send 60wt% of the mixed fiber containing nano silver alginate fiber and 40wt% of copper alginate fiber to the opener to maximize the fluffy state and mix them evenly.

[0044] ③Carding: the opened mixture containing nano-silver alginate fiber and copper alginate fiber is fed into a carding machine through a cotton feeding system to be carded into a fiber web; during this process, the indoor temperature is controlled at 18-23°C and relative humidity Control at 60-90%, the main cylinder frequency of the carding machine is controlled at 600-800r / min, and the feeding speed is controlled at 1-3m / min.

[0045] ④Laying the net: Repeatedly overlap the fiber net after carding, and the single net weight is 8g. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com