A kind of slow descender damping device for metal particle medium

A metal particle and damping device technology, applied in life-saving equipment, building rescue, etc., can solve the problems of high cost, high requirements on assembly accuracy and airtightness, fear of water, etc., and achieves anti-corrosion, assembly accuracy and low requirements on mechanism airtightness. , the effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

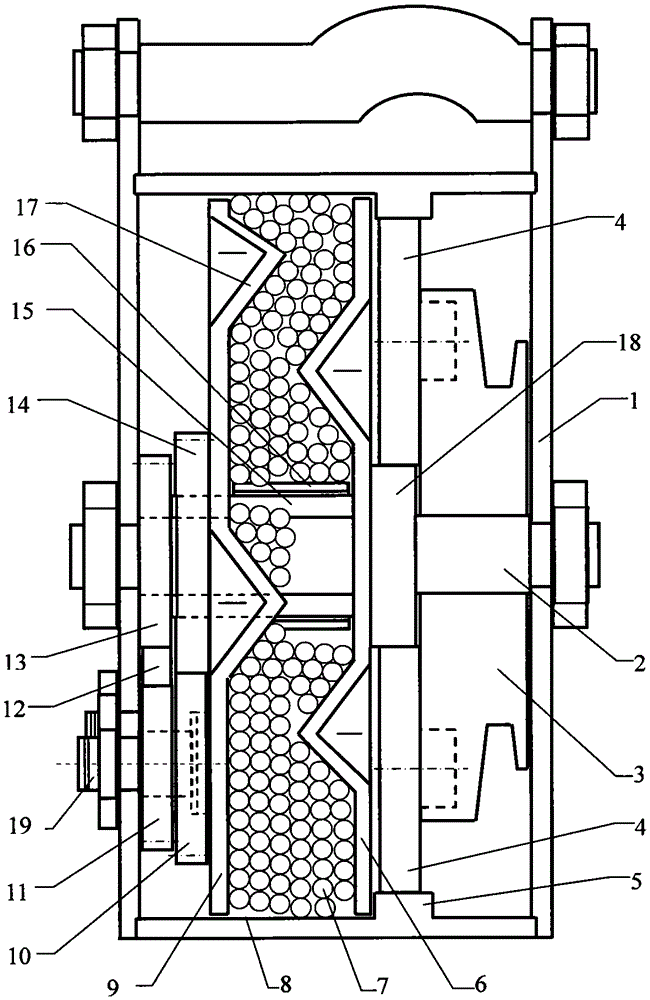

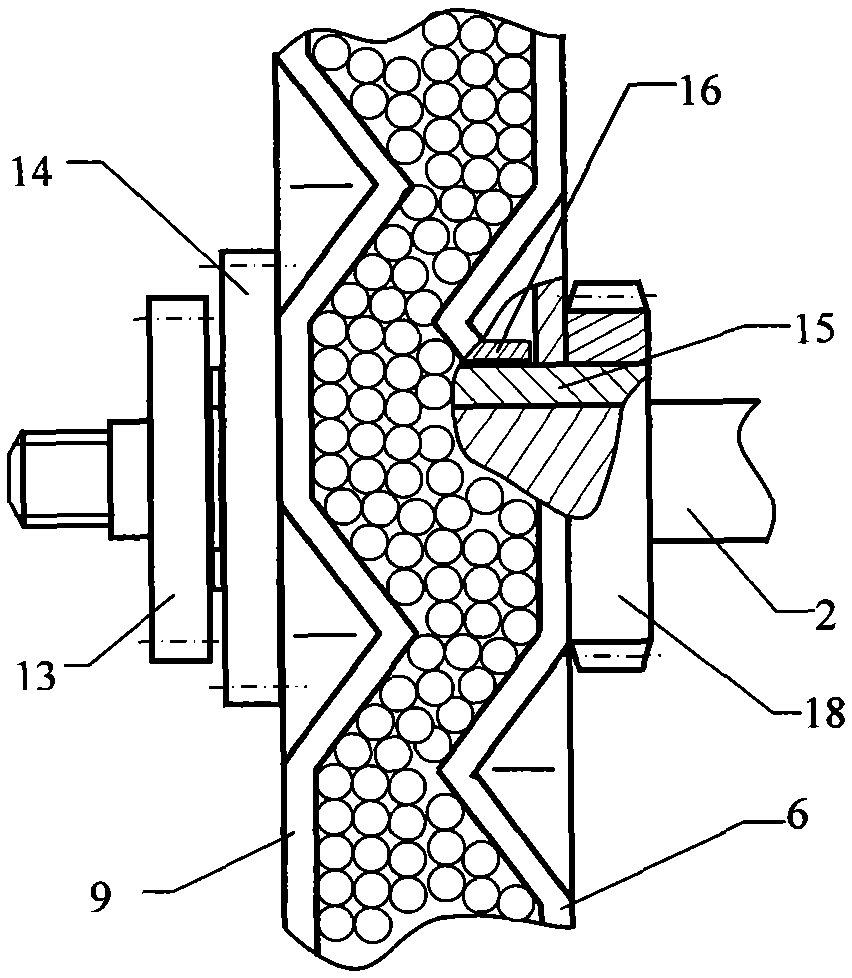

[0025] figure 2 A schematic diagram of the local structure of a slow descender damping device for granular media (hereinafter referred to as the damping device) provided by the present invention. descender such as figure 1 shown. The structure, assembly relationship and working principle of this damping device are as follows:

[0026] Such as figure 1 As shown, the rope winding mechanism mainly includes the rope wheel 3 and the central shaft 2; the speed-up mechanism includes the planetary gear 4, the ring gear 5 and the central gear 18; as figure 1 , Figure 7 As shown, the counter gear set is mainly composed of counter driving gear 13, gear A12, gear B11, gear C10 and counter driven gear 14.

[0027] exist figure 1 Among them, the sheave 3 is movably assembled with the central shaft 2, and the gear shafts of the planetary gears 4 (2 or 3) are fixedly installed on the sheave 3, and the planetary gears 4 mesh with the inner ring gear 5 of the box body respectively, ...

Embodiment 2

[0032] Such as Figure 8 As shown, compared with the slow descender of embodiment 1, the entire slow descender has a rope winding mechanism, a gear speed-up mechanism, and a damping device that are not on the same central axis, but are arranged in parallel and separated and connected to each other. In the entire descender, all the gears are ordinary cylindrical gears with external meshing. The advantage is that it is easy to process and manufacture, and the cost is low. The disadvantage is that the overall size of the descender is slightly larger, but the speed ratio can achieve a larger value. In this embodiment The rotational speed ratio of the rope wheel 3 and the damping wheel is 1:6. The counter gear set has been simplified, and mainly consists of a counter driving gear 13 and a counter driven gear 14 . The rope wheel 3 directly drives the forward damping wheel 6 to rotate through the speed-up gear on the left, and the rope wheel 3 drives the reverse damping wheel 9 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com