Method for cleaning external tubular membrane for deeply treating waste incineration leachate

A waste incineration and advanced treatment technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem that the membrane flux cannot achieve a high recovery rate, the membrane flux cannot be effectively recovered, and chemical reagents Consumption and other problems, to shorten the time, improve the degree of recovery, reduce pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

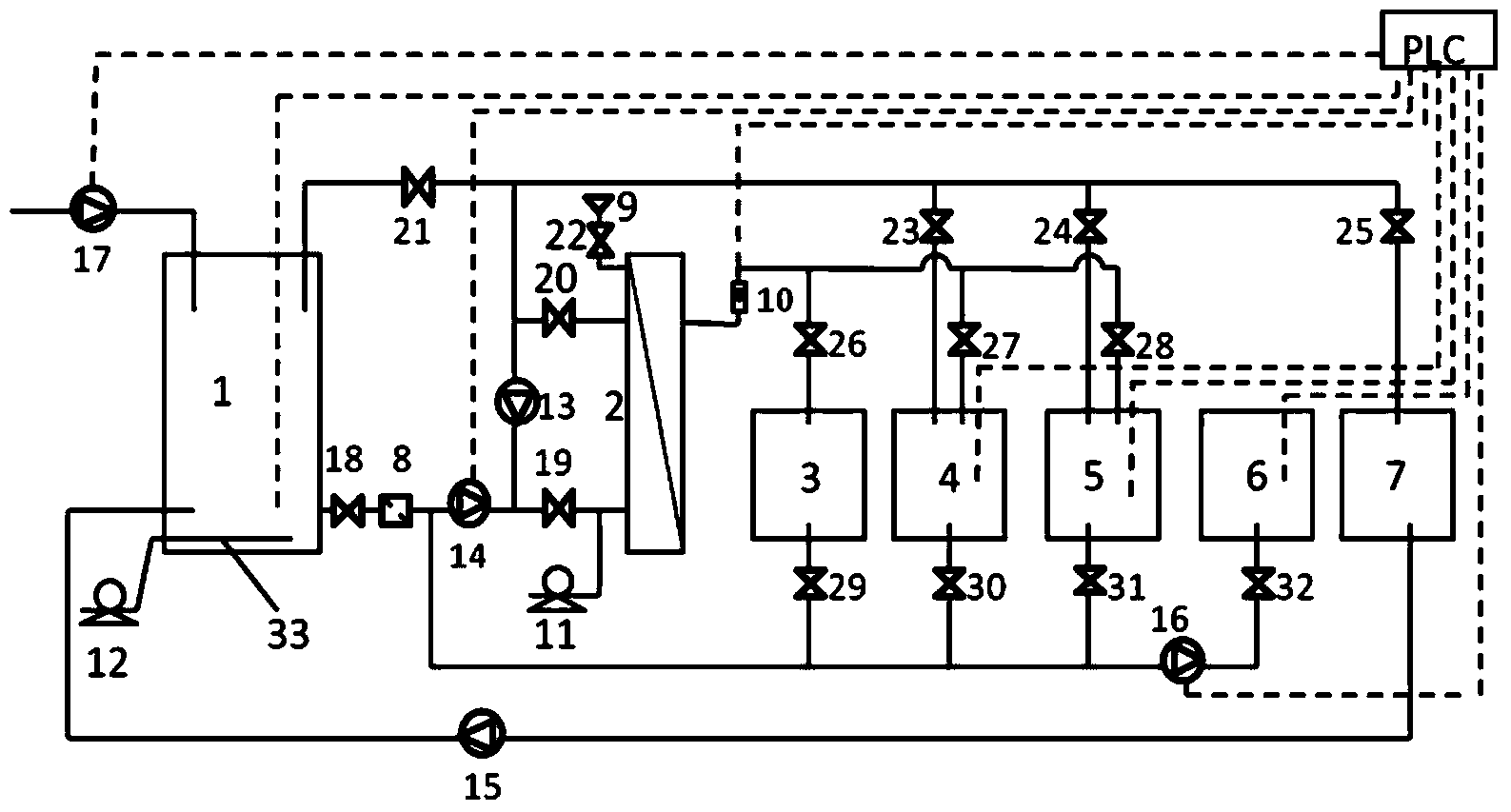

[0039] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

[0040] An external tubular membrane cleaning method for advanced treatment of waste incineration leachate mainly includes the following steps:

[0041] (1) Clean water flushing: Use conventional methods to carry out clean water flushing, mainly to discharge the muddy water in the membrane tube.

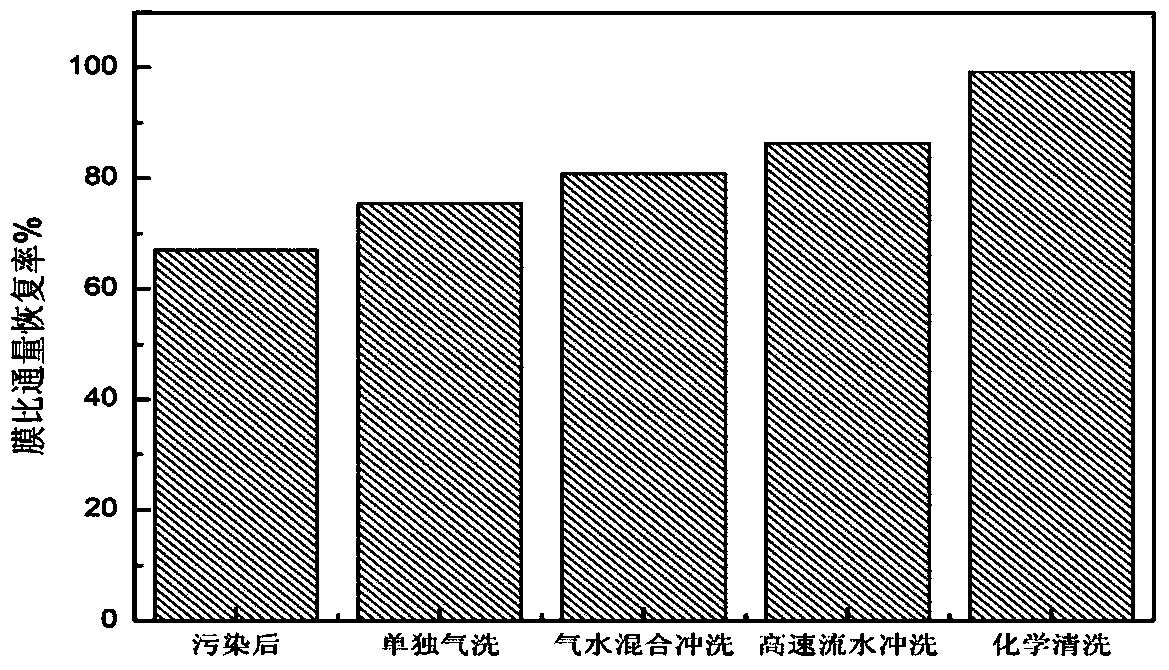

[0042] (2) Separate air washing: close the valves of the water inlet and return port of the membrane module, and only air is introduced into the membrane module, and the air bubbles formed in the water of the gas injected into the membrane module will wash away the mud cake layer on the membrane surface, making the mud cake layer loose , to facilitate subsequent cleaning to remove the mud cake layer on the membrane surface.

[0043] (3) Air-water mixed flushing: The membrane module is flushed with an air-water flushing fluid with a volume ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com