Electrostatic trapping device for fine particles based on rotating polar lines

A fine particle, electrostatic capture technology, applied in the direction of electrostatic separation, electrostatic effect separation, external electrostatic separator, etc., can solve the problems of single function and poor capture effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

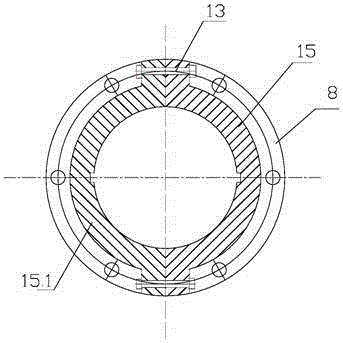

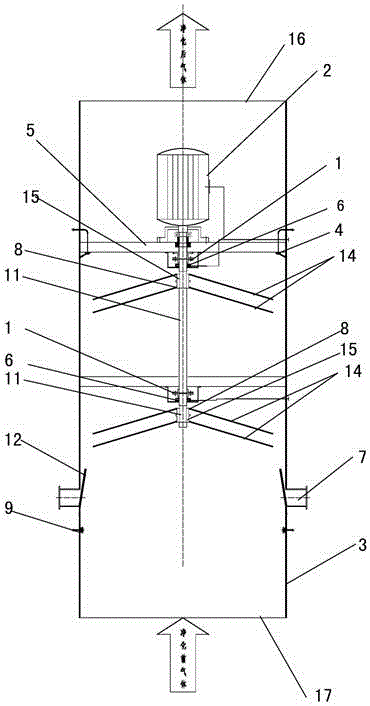

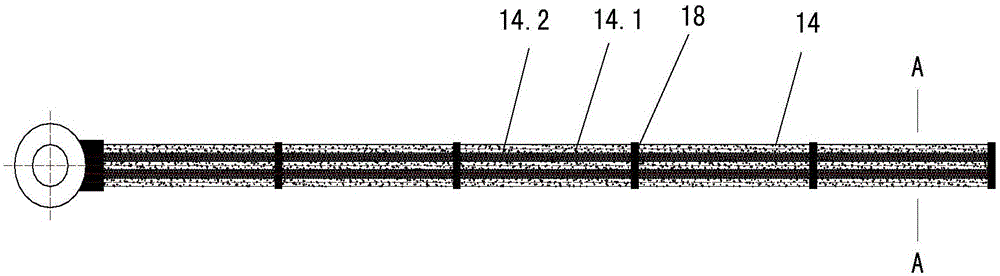

[0035] Below in conjunction with accompanying drawing, device of the present invention is further explained:

[0036] The bottom of the cylinder 3 is provided with an air inlet 16, and the top is provided with an air outlet 17. A motor 2 is provided at the central axis of the cylinder 3 on the upper section of the cylinder 3, and the motor 2 is fixed on the inner wall of the cylinder 3 via a support beam 5. The rotating shaft of the motor 2 (one motor is used in this embodiment) is connected in series with two layers (could be multi-layer, two layers in this embodiment) of electrostatic components, and the electrostatic components include an insulating coupling 1 and an insulating wire The live shaft 11 connected by the coupling 1 (which can be guided and supported by the bearing system), through the insulating coupling 1, the rotating shaft of the motor 2 is insulated from the live shaft 11 and the live shaft 11 in different electrostatic components to avoid The rotating shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com