Method for treating surface of glass accessory

A technology of surface treatment and accessories, which is applied in the field of surface treatment of glass accessories, can solve problems affecting production costs, troublesome operation, and many processes, and achieve the effects of improving installation adhesion, good surface bonding state, and optimizing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

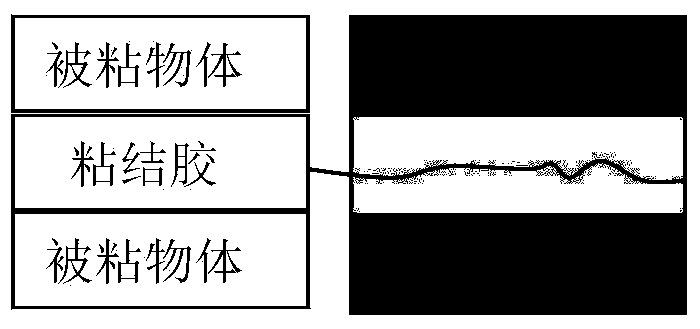

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A surface treatment method for a glass accessory, comprising the steps of:

[0037] (1) First place the glass accessory on the positioning plate, then place the glass accessory on the primer head in the alcohol bottle with the manipulator, clean the bonding area on the surface of the glass accessory, and blow the bonding area with 0.6MPa compressed gas 3s; every time 12 racks are wiped, the alcohol bottle will automatically switch to a primer head;

[0038] (2) Treat the bonded area of the glass accessory treated in step (1) with plasma equipment. The specific technical parameters are: the input pressure of the plasma equipment is 0.4MPa, the particles above 0.3μm are filtered out, and the oil content at 20°C is less than 0.1 mg / m 3 , try to ensure that there is no water and no oil, use the plasma outer flame to treat the bonding area at a speed of 120mm / s according to the glue track, and the spray gun nozzle of the plasma equipment is 15.5mm away from the bonding ar...

Embodiment 2

[0041] A surface treatment method for a glass accessory, comprising the steps of:

[0042] (1) First place the glass accessory on the positioning plate, then place the glass accessory on the primer head in the alcohol bottle with the manipulator, clean the bonding area on the surface of the bracket, and blow the bonding area with 0.8MPa compressed air for 5 seconds ;When wiping 12 racks, the alcohol bottle automatically switches to a primer head;

[0043] (2) Treat the bonded area of the glass accessory treated in step (1) with plasma equipment. The specific technical parameters are: the input pressure of the plasma equipment is 0.6MPa, the particles above 0.3μm are filtered out, and the oil content at 20°C is less than 0.1 mg / m 3 , try to ensure that there is no water and no oil, use the plasma outer flame to treat the bonding area at a speed of 80mm / s according to the glue track, and the nozzle of the plasma equipment is 11.5mm away from the bonding area;

[0044] (3) Ev...

Embodiment 3

[0046] A surface treatment method for a glass accessory, comprising the steps of:

[0047] (1) First place the glass accessory on the positioning plate, then place the glass accessory on the primer head in the alcohol bottle with the manipulator, clean the bonding area on the surface of the bracket, and blow the bonding area with 0.7MPa compressed air for 4s ;

[0048] (2) Treat the bonded area of the glass accessory treated in step (1) with plasma equipment. The specific technical parameters are: the input pressure of the plasma equipment is 0.5MPa, the particles above 0.3μm are filtered out, and the oil content at 20°C is less than 0.1 mg / m 3, use the plasma outer flame to treat the bonding area at a speed of 100mm / s according to the glue track, and the spray gun nozzle of the plasma device is 13.5mm away from the bonding area;

[0049] (3) Evenly coat the bonding area of the glass accessory treated in step (2) with primer DV954, and blow air on the bonding area for 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com