Method for preparing highly mono-dispersed metal nanoparticles in porous material

A technology of metal nanoparticles and porous materials, applied in the field of nanomaterials and nanometers, can solve the problems of easy aggregation of nanometer metals, reduction of specific surface area, easy blockage of pores, etc., and achieve the effect of short synthesis cycle, high activity and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

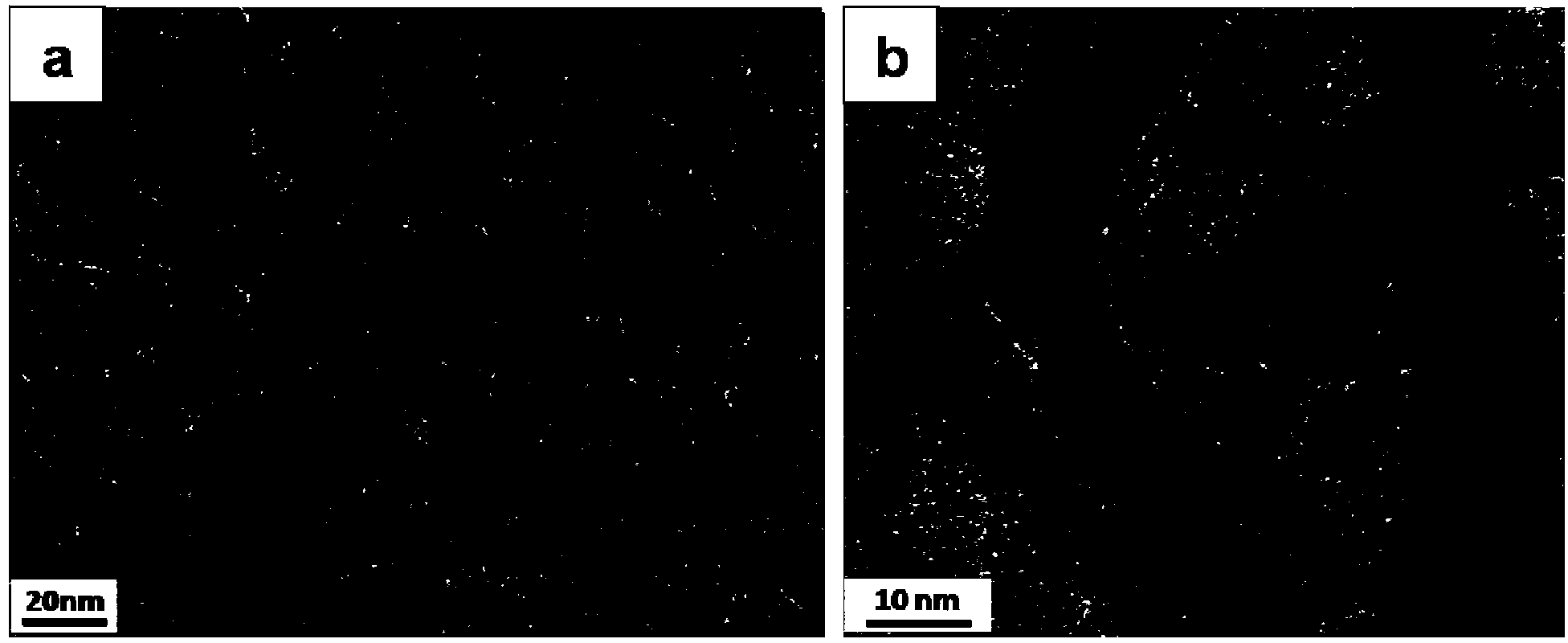

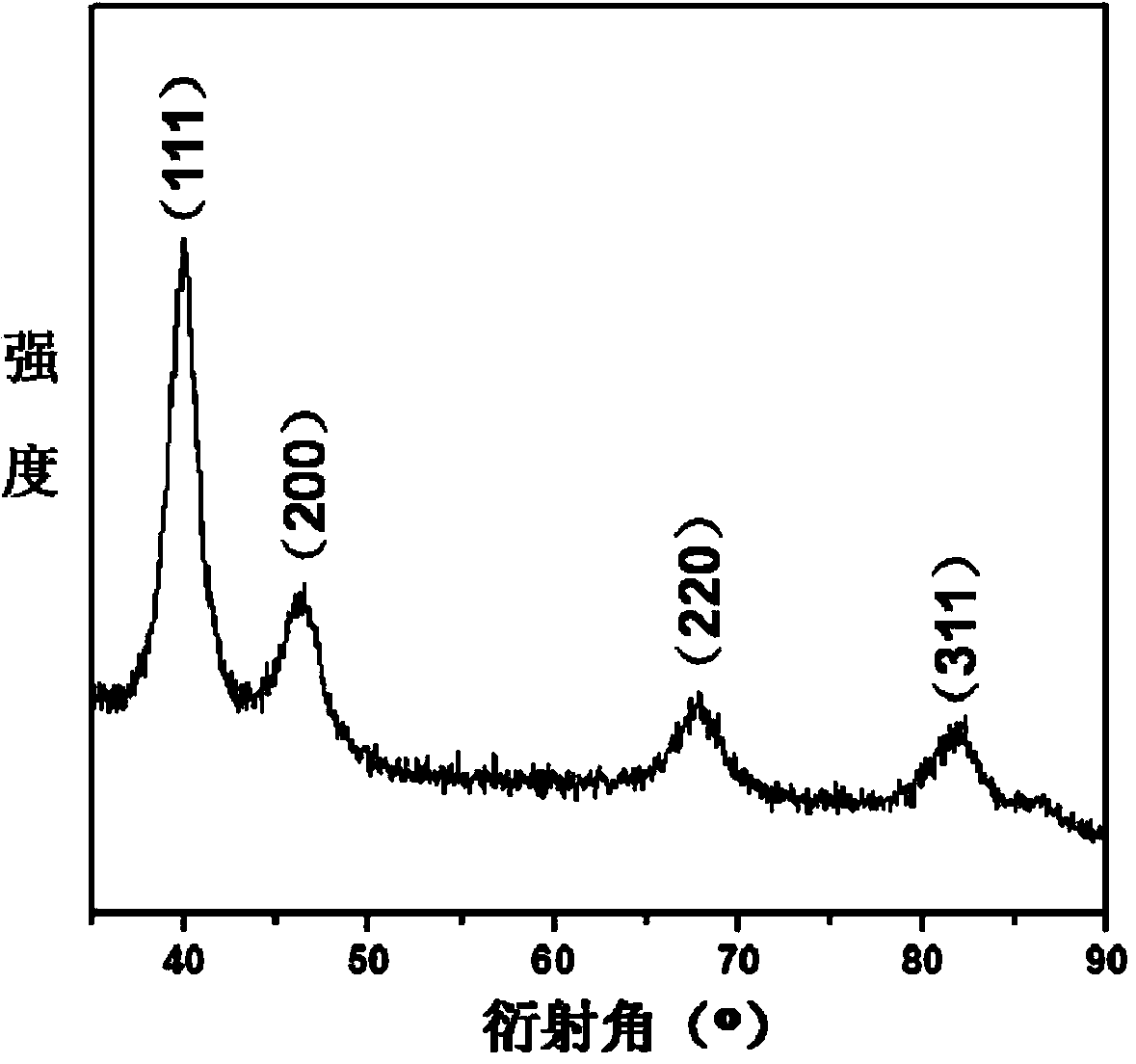

[0026] This example provides the preparation of a highly monodisperse bimetallic nanoparticle porous silica composite material (PtPdMCF), and the specific steps are as follows:

[0027] (1) Synthesis of porous silica material MCF with three-dimensional continuous penetration and uniform pore size:

[0028] At room temperature, add 1.5-2.5g of P123 and 1.5-2.5g of mesitylene into a hydrochloric acid solution with a concentration of 1.2-2.0M and a volume of 50-100mL, and mix well; then heat the mixed solution to 35-45°C, After 1 to 2 hours, add tetraethyl orthosilicate to the mixed solution and continue to stir at 35 to 45°C for 15 to 25 hours; then put the solution into the reaction kettle and age at 110 to 130°C for 20 to 30 hours; finally The obtained product is filtered, washed, dried in the air, and then calcined at 500-600° C. under atmospheric conditions for more than 5 hours to obtain the porous material MCF.

[0029] (2) Dissolve 0.1-1.0 g of the porous material MCF sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com