Co3O4/In2O3 heterostructure nanotube and preparation method and application thereof

A heterostructure and nanotube technology, which is applied in chemical instruments and methods, hollow filament manufacturing, filament/wire forming, etc., can solve the problems of complex and tedious processes, and the wall thickness of nanotube-like structures is not easy to control, and achieves cost-effective Inexpensive, good visible light catalytic activity, easy-to-form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

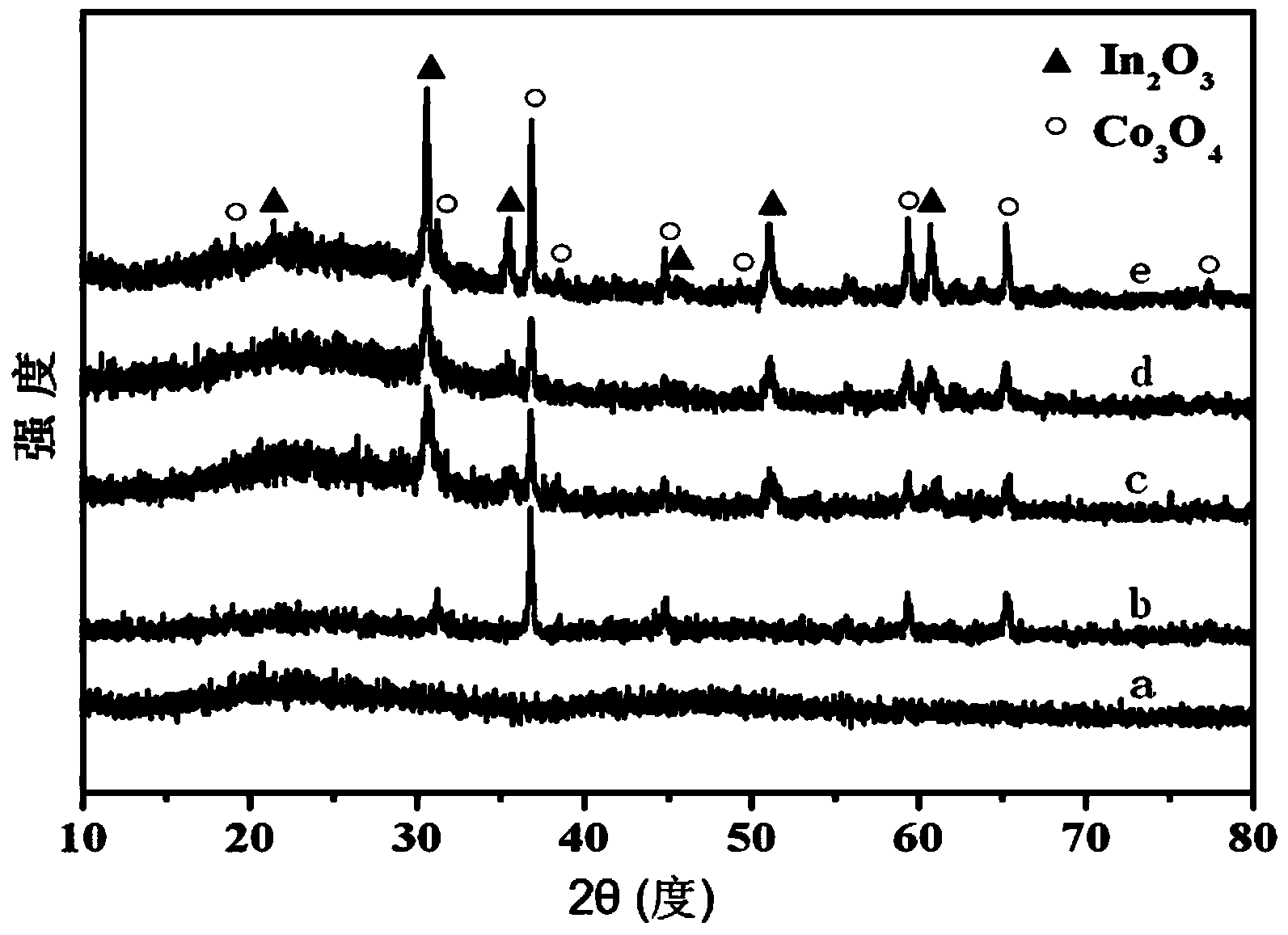

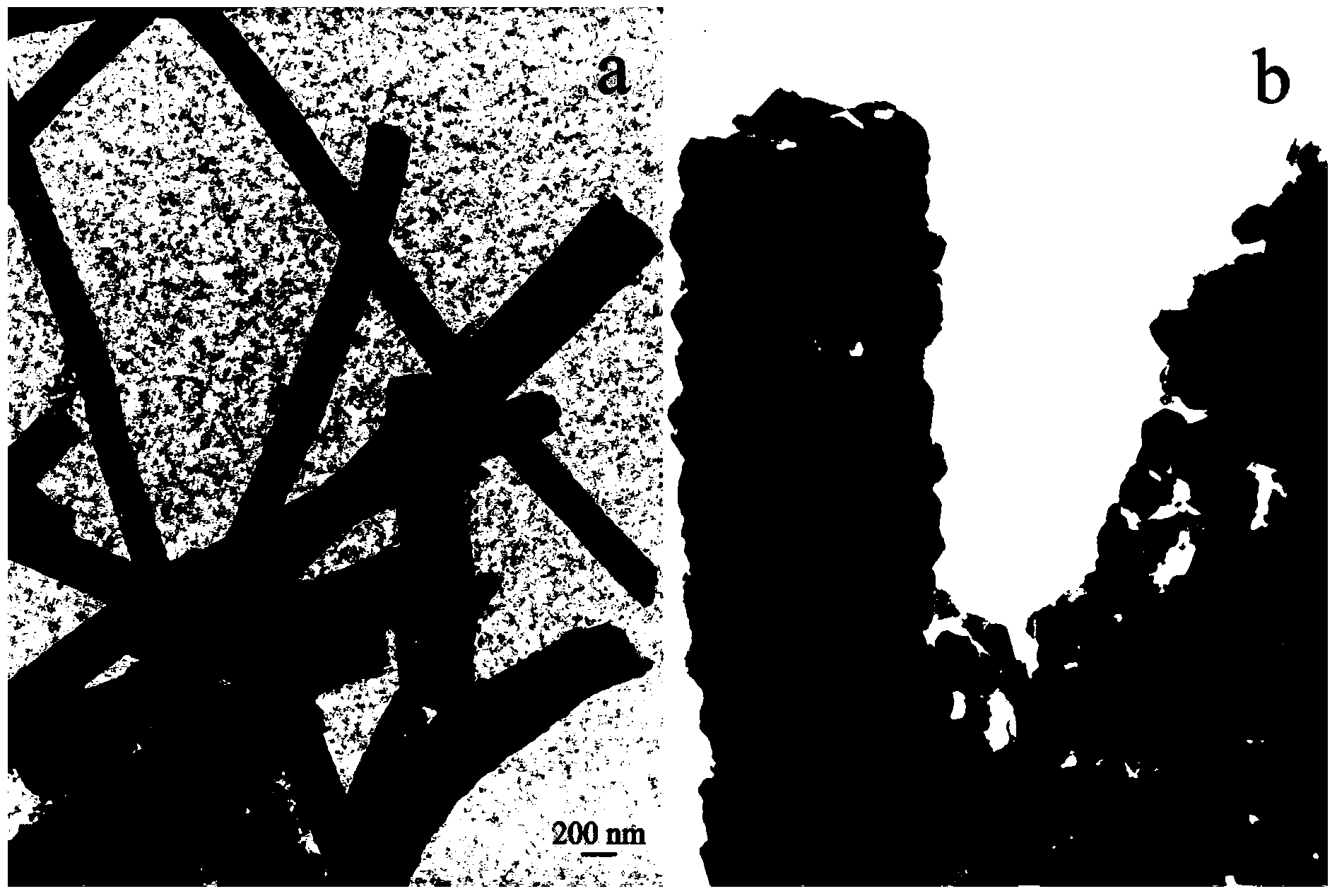

[0040] A kind of Co 3 o 4 / In 2 o 3 The preparation method of heterostructure nanotubes, the steps are as follows:

[0041] (1) 1.45g Co(NO 3 ) 2 ·6H 2 O (5mmol) and 0.95g In(NO 3 ) 3 4.5H 2 O (2.5mmol) was dissolved in a mixed solution of 16ml deionized water and 16ml absolute ethanol, and stirred until completely dissolved; 2.0g of polyvinylpyrrolidone (PVP) was added and stirred evenly to obtain a spinnability with a viscosity of 0.5Pa·S Sol;

[0042] (2) inject the spinnable sol prepared in step (1) into an electrospinning device, and perform electrospinning to obtain a precursor fiber;

[0043] Electrospinning conditions: spray the spinnable sol into the receiving plate with a plastic syringe with a stainless steel needle, the distance between the needle of the syringe and the receiving plate is 20cm, and the spray rate of the spinnable sol is 1.5mL / h , the voltage is 20kV, and the electrospinning temperature is controlled at 25°C;

[0044] (3) Dry the precurs...

Embodiment 2

[0053] A kind of Co 3 o 4 / In 2 o 3 The preparation method of heterostructure nanotubes, the steps are as follows:

[0054] (1) 1.45g Co(NO 3 ) 2 ·6H 2 O (5mmol) and 1.91g In(NO 3 ) 3 4.5H 2 O (5mmol) was dissolved in a mixed solution of 8ml deionized water and 8ml absolute ethanol, and stirred until completely dissolved; 1.0g polyvinylpyrrolidone was added, and stirred evenly to obtain a spinnable sol with a viscosity of 0.5Pa·S;

[0055] (2) inject the spinnable sol prepared in step (1) into an electrospinning device, and perform electrospinning to obtain a precursor fiber;

[0056] Electrospinning conditions: spray the spinnable sol into the receiving plate with a plastic syringe with a stainless steel needle, the distance between the needle of the syringe and the receiving plate is 25cm, and the spray rate of the spinnable sol is 1.5mL / h , the voltage is 20kV, and the electrospinning temperature is controlled at 25°C;

[0057] (3) Dry the precursor fibers prepar...

Embodiment 3

[0060] A kind of Co 3 o 4 / In 2 o 3 The preparation method of heterostructure nanotubes, the steps are as follows:

[0061] (1) 0.73g Co(NO 3 ) 2 ·6H 2 O (2.5mmol) and 0.95g In(NO 3 ) 3 4.5H 2 O (2.5mmol) was dissolved in a mixed solution of 11ml of deionized water and 5ml of absolute ethanol, and stirred until completely dissolved; 1.0g of polyvinylpyrrolidone was added, and stirred evenly to obtain a spinnable sol with a viscosity of 0.31Pa·S;

[0062] (2) inject the spinnable sol prepared in step (1) into an electrospinning device, and perform electrospinning to obtain a precursor fiber;

[0063] Electrospinning conditions: spray the spinnable sol into the receiving plate with a plastic syringe with a stainless steel needle, the distance between the needle of the syringe and the receiving plate is 25cm, and the spray rate of the spinnable sol is 1.5mL / h , the voltage is 20kV, and the electrospinning temperature is controlled at 25°C;

[0064](3) Dry the precursor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com