High temperature pressure sensor and preparation method thereof

A pressure sensor, high temperature technology, applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve the problems of product failure, rise, no record of PN junction leakage current, etc., and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

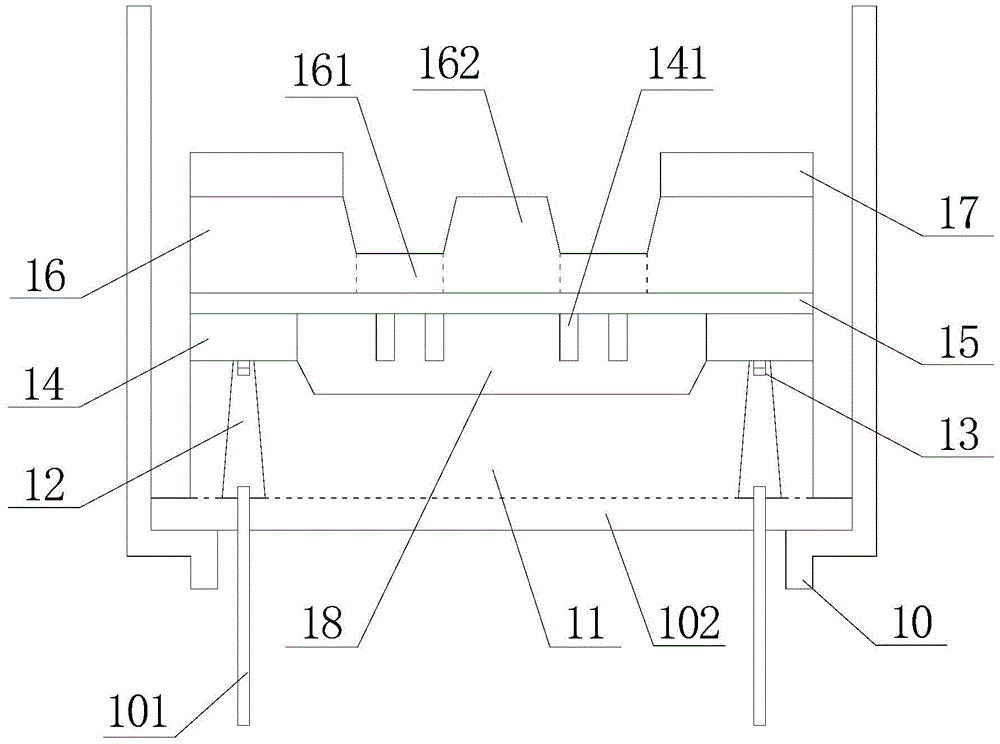

[0049] figure 1 It is a structural schematic diagram of an embodiment of the high temperature pressure sensor of the present invention; as figure 1 Shown, a high temperature pressure sensor, including:

[0050]A base 10 made of a metal material (such as stainless steel) is provided with a base glass 102 sintered with glass glue; preferably, the above-mentioned base 10 is hollow cylindrical to be sleeved on on the base glass 102, and the base 10 is also provided with an inwardly convex protruding structure for supporting the edge portion of the base glass 102, that is, the middle part of the base glass 102 is not in contact with the base 10, and then The base glass 102 and the base 10 form a barrel-shaped structure, the base glass 102 serves as the bottom of the barrel-shaped structure, and the base 10 serves as the sidewall of the barrel-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com