All-solid LMA (large mode area) photonic band gap optical fiber

A photonic bandgap and large mode field technology, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problem of difficult large mode field transmission, and achieve the effect of low binding loss, low bending loss and regular mode field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

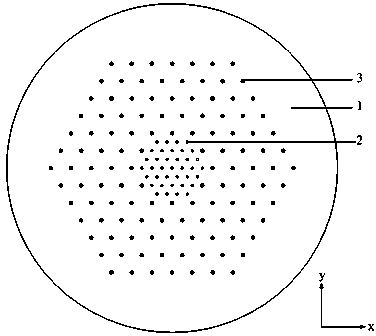

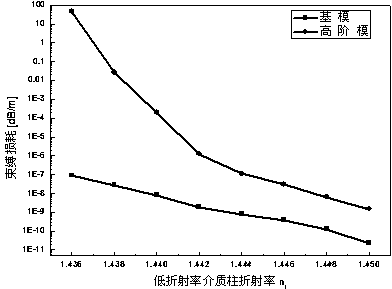

[0047] figure 1 A schematic cross-sectional view of one embodiment of the invention is given. The matrix material is pure quartz, and the material of the high-refractive-index medium column and the low-refractive-index medium column is doped quartz material. Among them, the period Λ of the low refractive index dielectric column (2) l =5.5 μm, diameter d l =1.2 μm, refractive index n l =1.44; the period Λ of the high refractive index medium column (3) h =11 μm, diameter d h =1.8 μm, the refractive index n h =1.48; the refractive index of the matrix material (1) n b =1.45. That is, the fiber core is formed by missing 7 high-refractive-index dielectric columns (3) in the periodic grid, and then arranging low-refractive-index dielectric columns (2), that is, m=2, N=2, and the low-refractive-index dielectric columns ( 2) The number of layers is 2×2-1=3. When the bending radius is 16-52 cm, the bending loss of the high-order mode of the fiber is greater than 10 dB / m, while ...

Embodiment 2

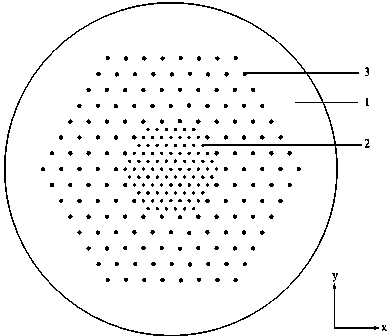

[0049] In order to further increase the mode field area of the fiber, figure 2 A cross-sectional view of another embodiment of the invention is shown. The period Λ of the low refractive index dielectric column (2) l =5.5 μm, diameter d l =1.2 μm, refractive index n l =1.436; period Λ of high refractive index medium column (3) h =11 μm, diameter d h =1.8 μm, the refractive index n h =1.48; the refractive index of the matrix material (1) n b =1.45. That is, the fiber core is formed by missing 7 high-refractive-index dielectric columns (3) in the periodic grid, and then arranging low-refractive-index dielectric columns (2), that is, m=3, N=2, and the low-refractive-index dielectric columns ( 2) The number of layers is 3×2-1=5. When the bending radius is 24-32 cm, the bending loss of the high-order mode of the fiber is greater than 10 dB / m, while the bending loss of the fundamental mode is less than 0.1 dB / m. It can be considered that the fiber can transmit single-mode ...

Embodiment 3

[0051] This embodiment provides a large mode field bandgap fiber that can be transmitted in a single mode without bending under a straight fiber. Its cross-sectional diagram is shown in figure 1 shown. Among them, the period Λ of the low refractive index dielectric column (2) l =5.5 μm, diameter d l =1.2 μm, refractive index n l =1.434; period Λ of high refractive index medium column (3) h =11 μm, diameter d h =1.8 μm, the refractive index n h =1.48; the refractive index of the matrix material (1) n b =1.45. That is, the fiber core is formed by missing 7 high-refractive-index dielectric columns (3) in the periodic grid, and then arranging low-refractive-index dielectric columns (2), that is, m=2, N=2, and the low-refractive-index dielectric columns ( 2) The number of layers is 2×2-1=3. Its mode field area can reach 693 μm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com