Method for preparing piezoelectric bimorph

A piezoelectric bimorph, piezoelectric body technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve problems such as device failure, bonding defects, bimorph failure, etc. Reliable work and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

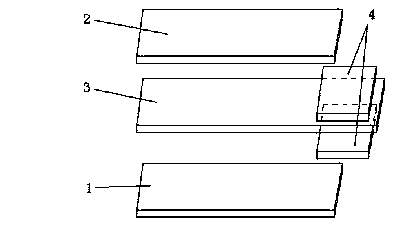

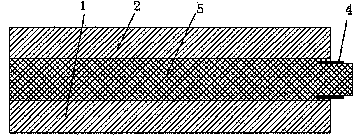

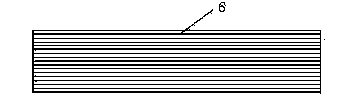

[0029] In this embodiment, the upper and lower piezoelectric bodies and the fiberboard prepreg adopt a rectangular structure, the electrode layer of the upper and lower piezoelectric bodies adopts gold electrodes, and the fiberboard prepreg is a unidirectional glass fiber prepreg, and the fiber bundle distribution is shown in image 3 ; The uncured prepreg resin in the fiberboard prepreg is epoxy resin, and the upper and lower piezoelectric bodies have the same size and the same material.

[0030] The piezoelectric bimorph preparation method in the present embodiment comprises the following steps:

[0031] Step 1: Wash the lower piezoelectric body 1 with electrodes and the upper piezoelectric body 2 with electrodes with water, alcohol and acetone, and dry them at 120°C for use;

[0032] Step 2: Cut the uncured fiberboard prepreg 3 into the required size for use;

[0033] Step 3: The lower piezoelectric body 1 with electrodes, the upper piezoelectric body 2 with el...

Embodiment 2

[0038] In this embodiment, the upper and lower piezoelectric body and the fiberboard prepreg adopt a rectangular structure, the electrode layer of the upper and lower piezoelectric body adopts silver electrodes, and the fiberboard prepreg is an ordinary two-way glass fiber prepreg, and the fiber bundle distribution is shown in Figure 4 ; The uncured prepreg resin in the fiberboard prepreg is epoxy resin, and the upper and lower piezoelectric bodies have the same size and the same material.

[0039] The piezoelectric bimorph preparation method in the present embodiment comprises the following steps:

[0040] Step 1: Wash the lower piezoelectric body 1 with electrodes and the upper piezoelectric body 2 with electrodes with water, alcohol and acetone, and dry them at 120°C for use;

[0041] Step 2: Cut the uncured fiberboard prepreg 3 into the required size for use;

[0042] Step 3: The lower piezoelectric body 1 with electrodes, the upper piezoelectric body 2 with ...

Embodiment 3

[0047] In this embodiment, the upper and lower piezoelectric body and the fiberboard prepreg adopt a rectangular structure, the electrode layer of the upper and lower piezoelectric body adopts silver-palladium electrodes, the fiberboard prepreg is a unidirectional carbon fiber prepreg, and the distribution of fiber bundles is the same as in Example 1. ; The uncured prepreg resin in the fiberboard prepreg is epoxy resin; the upper and lower piezoelectric bodies have the same size and the same material.

[0048] The piezoelectric bimorph preparation method in the present embodiment comprises the following steps:

[0049] Step 1: Wash the lower piezoelectric body 1 with electrodes and the upper piezoelectric body 2 with electrodes with water, alcohol and acetone, and dry them at 120°C for use;

[0050] Step 2: Cut the uncured fiberboard prepreg 3 into the required size for use;

[0051] Step 3: The lower piezoelectric body 1 with electrodes, the upper piezoelectric b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com