Motor speed-regulation system energy-saving controller based on super-capacitor energy storage and control method

A supercapacitor and motor speed regulation technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of low operating efficiency of the motor speed regulation system, inability to effectively realize energy storage and reuse, and achieve storage and reuse, and improve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

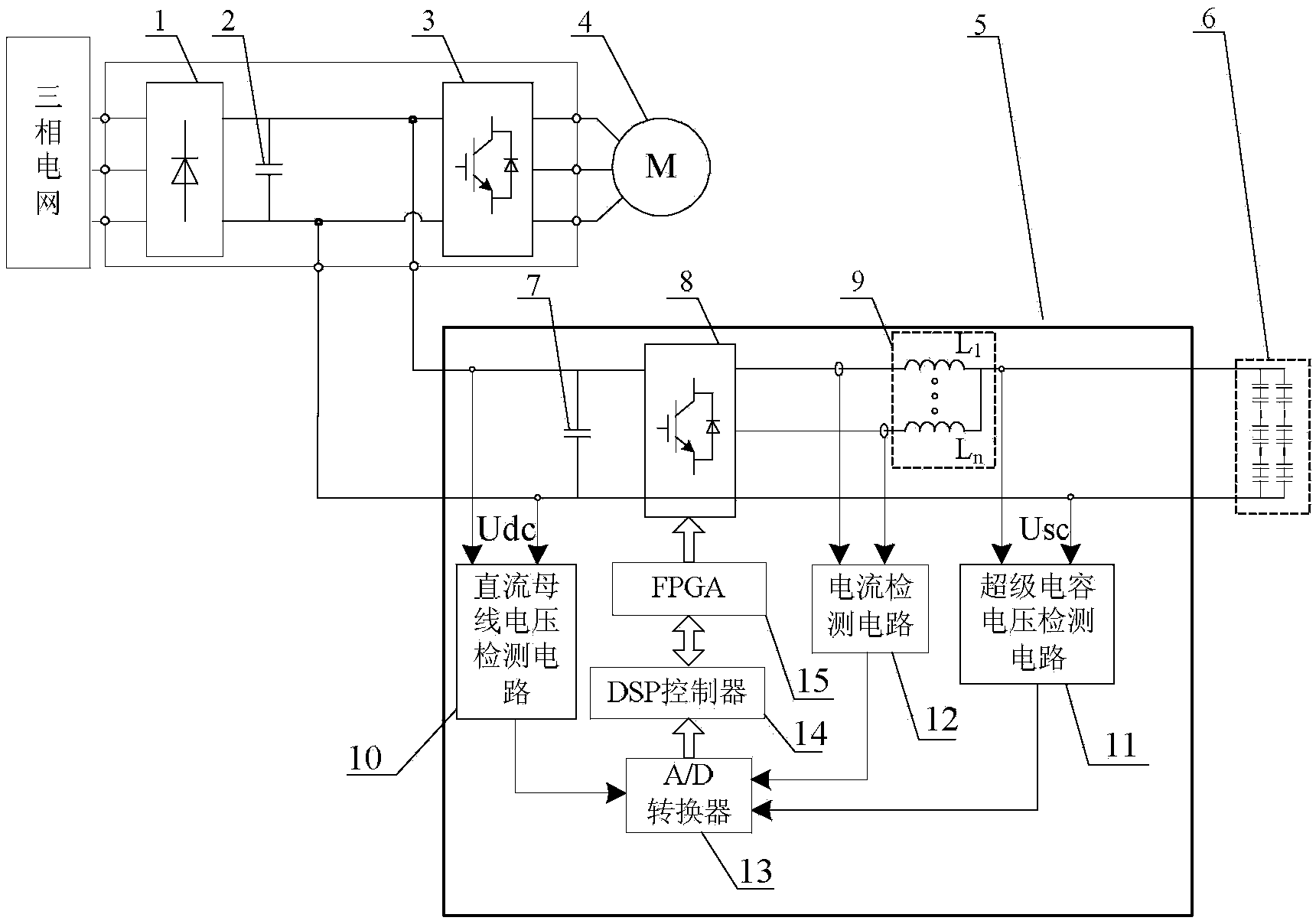

[0022] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the energy-saving controller of the motor speed regulation system based on supercapacitor energy storage described in this embodiment, it includes a diode rectifier bridge 1, a first DC filter capacitor 2, an inverter 3, a bidirectional DC / DC power converter 5 and supercapacitor module 6,

[0023] The bidirectional DC / DC power converter 5 includes a second DC filter capacitor 7, an n-fold IGBT bridge circuit 8 and n filter inductors 9, wherein the n filter inductors include the first filter inductor L 1 , the second filter inductance L 2 ...the nth filter inductor Ln, where n is a positive integer, the DC bus voltage detection circuit 10, the supercapacitor voltage detection circuit 11, the current detection circuit 12, the A / D converter 13, the DSP controller 14 and the FPGA15,

[0024] The three-phase AC input terminal of the diode rectifier bridge 1 is connected to the three-phase grid, ...

specific Embodiment approach 2

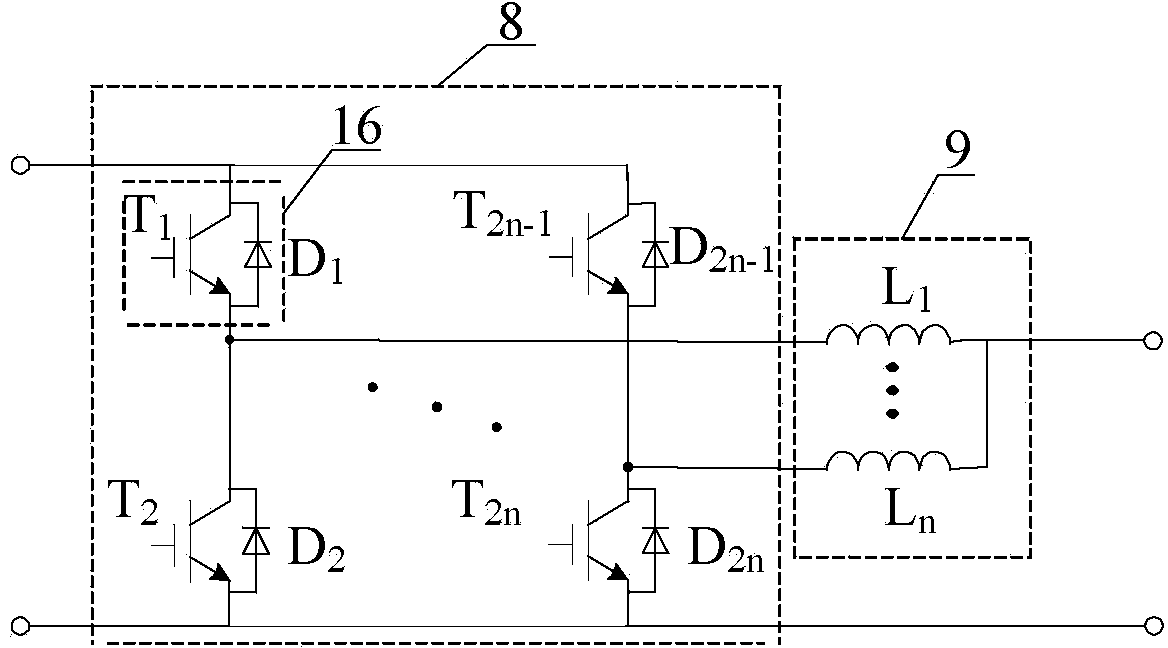

[0034] Embodiment 2. The difference between this embodiment and the energy-saving controller of the motor speed regulation system based on supercapacitor energy storage described in Embodiment 1 is that the n-fold IGBT bridge circuit 8 includes 2n full control circuits 16, n is a positive integer, two full-control circuits 16 are connected to form a bridge arm, and the midpoint of each bridge arm is connected to a filter inductor L k , where, k=1~n, k is a positive integer;

[0035] Each of the full control circuits 16 includes an IGBT T 1 and diode D 1 , IGBT T 1 The collector of the diode D is connected 1 Cathode of IGBT T 1 The emitter of the diode D is connected 1 the anode.

[0036] In this embodiment, each IGBT is connected in antiparallel to each diode.

specific Embodiment approach 3

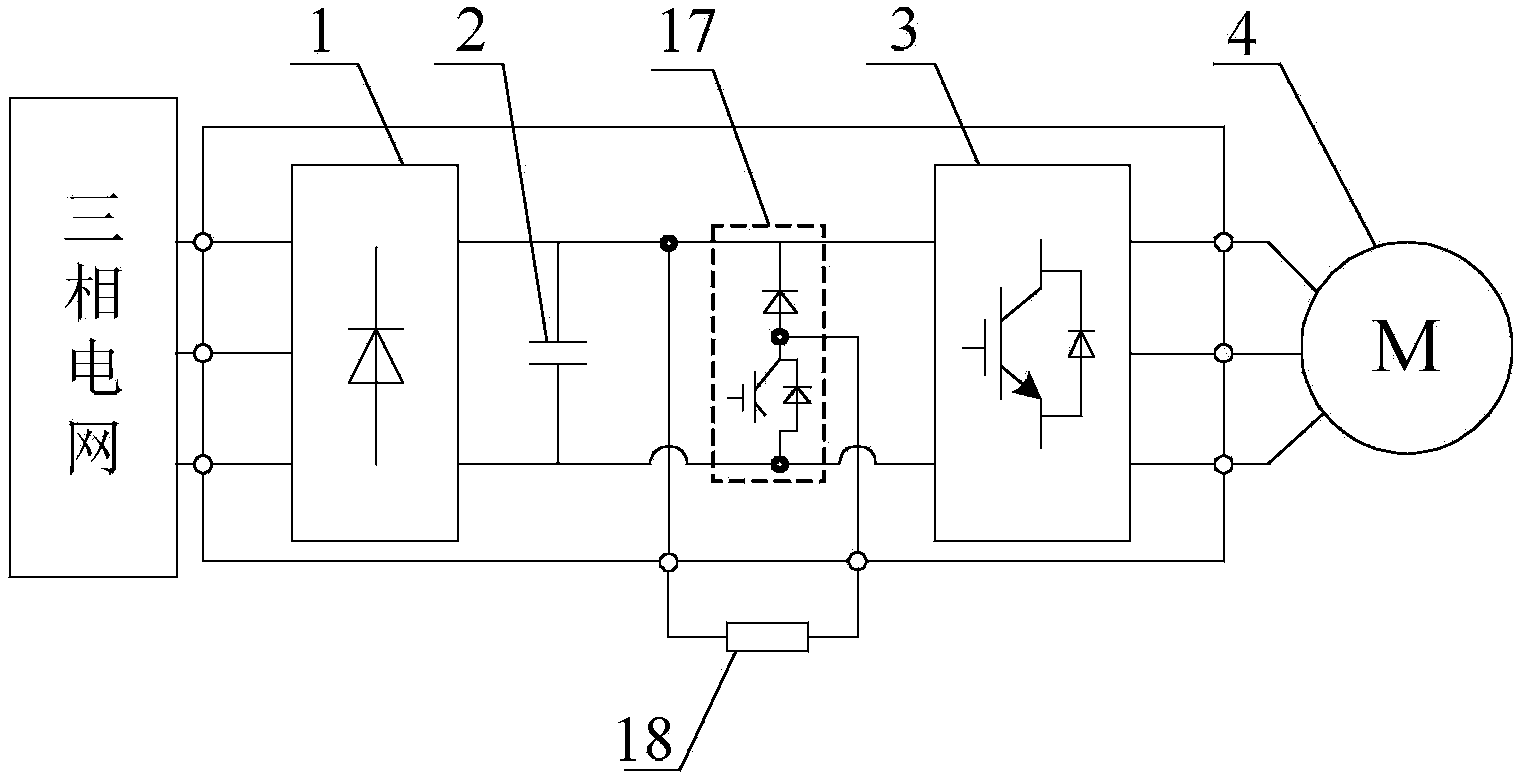

[0037] Embodiment 3. The difference between this embodiment and the energy-saving controller of the motor speed regulation system based on supercapacitor energy storage described in Embodiment 1 is that the supercapacitor module 6 includes two sets of capacitors and the two sets of capacitors are connected in parallel. , each capacitor group is composed of a plurality of capacitors connected in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com