Long-acting frozen sweet dough and preparation process thereof

A technology for freezing dough and preparation process, which is applied in the processing of dough, dough ready for oven, baking, etc. It can solve the problem of only a few days at the longest and no more than 14 days, and the commercial use of dough is unsatisfactory, etc. problems, to achieve the effect of convenient purchase and use, convenient distribution, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

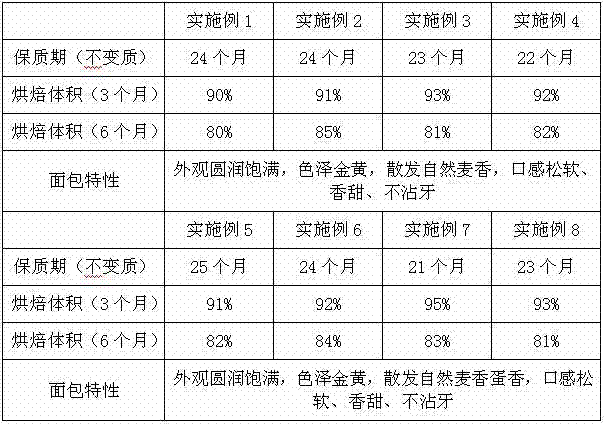

Examples

Embodiment 1

[0084] A long-lasting frozen sweet dough, comprising the following raw materials in parts by weight: 100 parts of high-gluten flour, 0.5 parts of emulsifier, 1 part of semi-dry yeast, 2 parts of frozen dough improver, 15 parts of sugar, 1 part of salt, and 8 parts of vegetable oil and 45 parts of water. The emulsifier is monoglyceride, and the frozen dough improver is Eskimo improver.

[0085] A preparation technique for long-acting frozen sweet dough, comprising the following processing steps:

[0086]Step A, material selection: sieve the selected high-gluten flour, the mesh number of the sieve is 40 mesh, set aside;

[0087] Step B. Stirring: Put the above-mentioned high-gluten flour, emulsifier, semi-dry yeast, frozen dough improver, sugar, salt, vegetable oil and water into the mixer and stir evenly. The stirring time is 15 minutes, and the stirring temperature is controlled at 24 ℃;

[0088] Step C. Segmentation and shaping: Put the stirred material into the division a...

Embodiment 2

[0091] A long-lasting frozen sweet dough, comprising the following raw materials in parts by weight: 100 parts of high-gluten flour, 1 part of emulsifier, 2 parts of semi-dry yeast, 2 parts of frozen dough improver, 20 parts of sugar, 2 parts of salt, and 10 parts of vegetable oil and 50 parts of water. The emulsifier is monoglyceride, and the frozen dough improver is Angel Diamond 99 frozen dough improver.

[0092] A preparation technique for long-acting frozen sweet dough, comprising the following processing steps:

[0093] Step A, material selection: sieve the selected high-gluten flour, the mesh number of the sieve is 45 mesh, set aside;

[0094] Step B, stirring: Put the high-gluten flour, emulsifier, semi-dry yeast, frozen dough improver, sugar, salt, vegetable oil and water into the mixer and stir evenly. The stirring time is 18 minutes, and the stirring temperature is controlled at 20 ℃;

[0095] Step C. Segmentation and shaping: Put the stirred material into the di...

Embodiment 3

[0098] A long-lasting frozen sweet dough, comprising the following raw materials in parts by weight: 100 parts of high-gluten flour, 1.5 parts of emulsifier, 3 parts of semi-dry yeast, 3 parts of frozen dough improver, 25 parts of sugar, 2 parts of salt, and 12 parts of vegetable oil and 60 parts of water. The emulsifier is a mixture of sucrose fatty acid ester monoglyceride, sucrose fatty acid ester diglyceride, and sucrose fatty acid ester triglyceride in a mass ratio of 1.5:2:1. The frozen dough improver is Meishan Marley frozen dough improver.

[0099] A preparation technique for long-acting frozen sweet dough, comprising the following processing steps:

[0100] Step A, material selection: sieve the selected high-gluten flour, the mesh number of the sieve is 50 mesh, set aside;

[0101] Step B. Stirring: put the above-mentioned high-gluten flour, emulsifier, semi-dry yeast, frozen dough improver, sugar, salt, vegetable oil and water into the mixer and stir evenly. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com