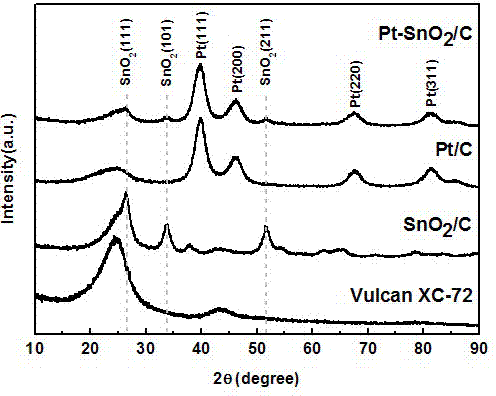

Method for preparing high-dispersibility nano Pt-SnO2/C catalyst

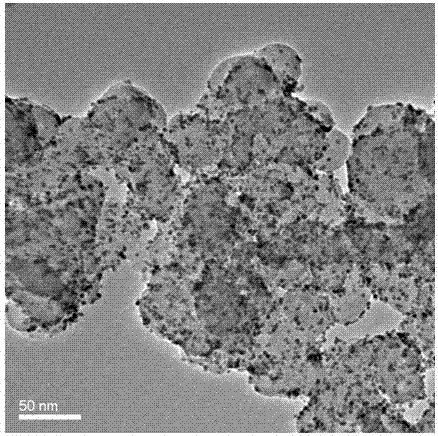

A pt-sno2, catalyst technology, applied in the chemical industry, can solve the problems of complex preparation process, poor loading morphology, etc., and achieve the effects of simple operation, uniform distribution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

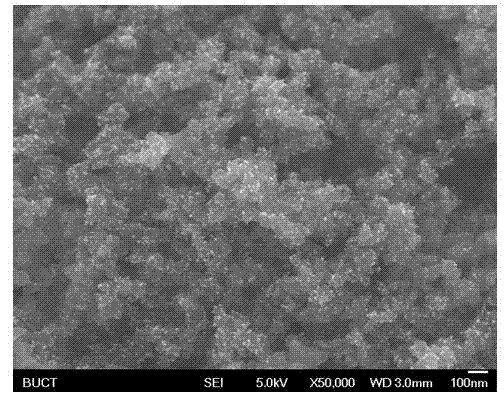

[0023] Preparation of Carbon Black-supported Nano-SnO Composite Catalyst with 20% Loading Capacity and Highly Dispersed Nano-Pt-SnO 2 / C Catalyst

[0024] (1) Preparation of 20% carbon black-supported nano-tin dioxide catalyst by ultrasonic method

[0025] In the 1g carbon black isopropanol solution acidified with nitric acid, the volume of isopropanol is 30~70ml, ultrasonically disperse for 5min~30min, so that the carbon black solution is evenly dispersed;

[0026] 20% SnO loading per unit mass of carbon black 2 Add soluble tin salt to the carbon black solution, adjust the pH value of the solution to 1~3 at the same time, put it into an ultrasonic washing machine for 10~100min, and the ultrasonic power is 30Hz~100Hz to obtain acidified carbon black containing tin salt the suspension;

[0027] Put the solution into an oven for drying at a temperature of 60°C to 100°C, collect the sample after evaporating to dryness, and heat-treat the solid powder under the conditi...

Embodiment 2

[0032] Preparation of 40% Carbon Black-supported Nano-SnO Composite Catalyst and Highly Dispersed Nano-Pt-SnO2 / C Catalyst

[0033] (1) Preparation of 40% carbon black-supported nano-tin dioxide catalyst by ultrasonic method

[0034] In 1 g of carbon black isopropanol solution acidified with nitric acid, the volume of isopropanol is 30-70 parts by weight, ultrasonically dispersed for 5min-30min, so that the carbon black solution is evenly dispersed;

[0035] 40% SnO loading per unit mass of carbon black 2 Add soluble tin salt to the carbon black solution, adjust the pH value of the solution to 1~3 at the same time, put it into an ultrasonic washing machine for 10~100min, and the ultrasonic power is 10Hz~50Hz to obtain acidified carbon black containing tin salt the suspension;

[0036] Put the solution into an oven for drying at a temperature of 60°C to 100°C, collect the sample after evaporating to dryness, and heat-treat the solid powder under the condition of iner...

Embodiment 3

[0041] Preparation of Carbon Black-supported Nano-SnO Composite Catalyst with 60% Loading Capacity and Highly Dispersed Nano-Pt-SnO 2 / C Catalyst

[0042] (1) Preparation of 60% carbon black-supported nano-tin dioxide catalyst by ultrasonic method

[0043] In 1 g of carbon black isopropanol solution acidified with nitric acid, the volume of isopropanol is 10 to 100 parts by weight, ultrasonically dispersed for 5 min to 30 min, so that the carbon black solution is uniformly dispersed;

[0044] 60% SnO loading per unit mass of carbon black 2 Add soluble tin salt to the carbon black solution, adjust the pH value of the solution to 1~3 at the same time, put it into an ultrasonic washing machine for 10~100min, and the ultrasonic power is 10Hz~50Hz to obtain acidified carbon black containing tin salt the suspension;

[0045] Put the solution into an oven for drying at a temperature of 60°C to 100°C, collect the sample after evaporating to dryness, and heat-treat the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com