Improved strip steel weld joint mark hole detection device of cold rolling and pickling combined unit

A technology of combined unit and strip weld seam, applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of excessive thickness deviation, undetectable and disconnection of strip steel 3, and achieve the elimination of thickness deviation Excessive or broken bands to ensure accurate detection and increase the effect of the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

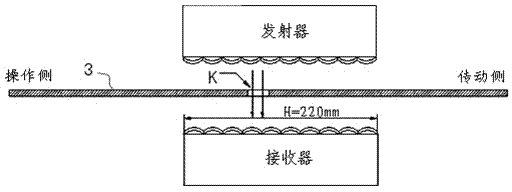

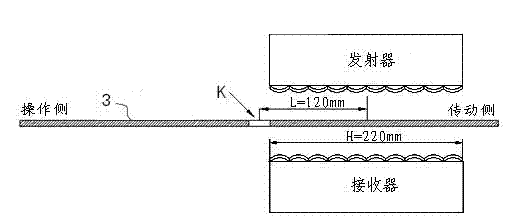

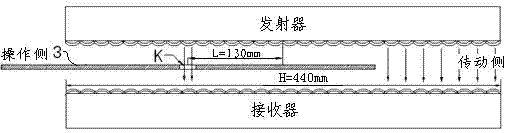

[0017] Example: such as Figure 5As shown, when the strip steel 3 deviates 130mm or more to the operating side, the 20mm diameter marking hole K punched in the middle of the width direction of the strip steel 3 is synchronously and horizontally moved to the left relative to the longitudinal center line of the entire weld marking hole detector side by side L=130mm or more, move out of the detection area with a width H of 220mm set by the main weld mark hole detector, and enter the detection area with a width H of 220mm set by the first weld mark hole detector, the operation side 1 # The grating emitter 1C emits a beam of infrared light with a wavelength of 875 nanometers, which is blocked by the strip steel 3, and the 1# grating receiver 1D will not be able to receive the infrared beam, and the 1# grating receiver 1D will send out a signal detecting the strip steel 3 The signal is sent to the control system, and the control system determines that the detection signal of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com