Vacuum pressure sensor detection device

A technology of vacuum pressure and detection device, used in measuring devices, vacuum gauges, measuring fluid pressure, etc., can solve problems such as malfunction of automation equipment, reduce production efficiency, and fast manipulator speed, and achieve the improvement of automation level, reduction of labor costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

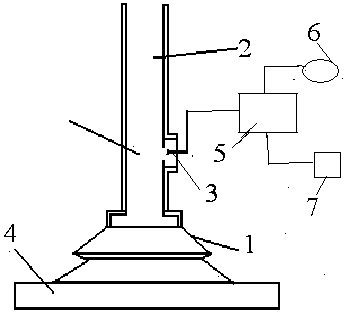

[0014] see figure 1 , a kind of vacuum pressure sensor detecting device of the present invention, comprises: vacuum generator, alarm 7 and control system 5, is provided with a sensor 3 for detecting self vacuum pressure on vacuum generator, then sensor 3 will detect The vacuum pressure is transmitted to the control system 5. When the vacuum pressure is lower than the set pressure value, the control system 5 triggers the alarm 7 and stops the equipment. The inspectors will deal with it after receiving the alarm signal. This detection method is reliable, effective and timely, which ensures the safe production.

[0015] Specifically, the vacuum generator includes: a vacuum suction cup 1 for absorbing a product 4 , and a suction cup guide rod 2 connected to the vacuum suction cup 1 . Such as figure 1 As shown, the product 4 is adsorbed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com