A Wax Polishing Method for Reducing Chemical Burns of Monocrystalline Silicon Wafer Polishing Sheets

A technology for chemical burns and polishing sheets, which is applied to chemical instruments and methods, cleaning methods using tools, cleaning methods using liquids, etc., to achieve good matching of chemical effects, improve process parameters, and reduce chemical burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Experimental material: 6-inch heavily doped silicon wafer to be thrown, resistivity 0.008-0.02Ω·cm 2 , the thickness is 625±15μm, and the quantity is 192 pieces.

[0033] Processing equipment: Wax single-sided polishing system (including one waxing machine, two rough polishing machines, one medium polishing machine, one fine polishing machine, one wafer downloading device, one ceramic disc cleaning machine, PTU Ceramic disc transfer device), one JAC cleaning machine after polishing, one pre-cleaning machine, CR81 silicon wafer surface particle tester.

[0034] Auxiliary materials: ceramic disc, disc brush, polishing pad, coarse polishing liquid, medium polishing liquid, fine polishing liquid, pure water, potassium hydroxide, acetic acid, PFA chip basket, lower chip shovel.

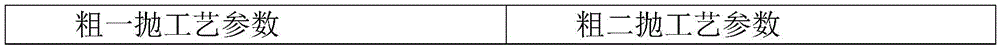

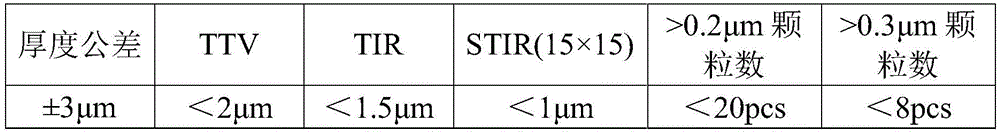

[0035] The middle throwing process and fine throwing process parameters are the same as the parameters in (6) (7) in the specific implementation steps, and the process parameters of the rough throw...

Embodiment 2

[0045] Experimental material: 6-inch lightly doped silicon wafer to be thrown, resistivity 2-10Ω·cm 2 , the thickness is 510±10μm, and the quantity is 192 pieces.

[0046] Processing equipment: Wax single-sided polishing system (including one waxing machine, two rough polishing machines, one medium polishing machine, one fine polishing machine, one wafer downloading device, one ceramic disc cleaning machine, PTU Ceramic disc transfer device), one JAC cleaning machine after polishing, one pre-cleaning machine, CR81 silicon wafer surface particle tester.

[0047] Auxiliary materials: ceramic disc, disc brush, polishing pad, coarse polishing liquid, medium polishing liquid, fine polishing liquid, pure water, potassium hydroxide, acetic acid, PFA chip basket, lower chip shovel.

[0048] The middle throwing process and fine throwing process parameters are the same as the parameters in (6) (7) in the specific implementation steps, and the process parameters of the rough throwing pr...

Embodiment 3

[0052] Experimental material: 5-inch lightly doped silicon wafer to be thrown, resistivity 3000-8000Ω·cm 2 , the thickness is 400±10μm, and the quantity is 192 pieces.

[0053] Processing equipment: Wax single-sided polishing system (including one waxing machine, two rough polishing machines, one medium polishing machine, one fine polishing machine, one wafer downloading device, one ceramic disc cleaning machine, PTU Ceramic disc transfer device), one JAC cleaning machine after polishing, one pre-cleaning machine, CR81 silicon wafer surface particle tester.

[0054] Auxiliary materials: ceramic disc, disc brush, polishing pad, coarse polishing liquid, medium polishing liquid, fine polishing liquid, pure water, potassium hydroxide, acetic acid, PFA chip basket, lower chip shovel.

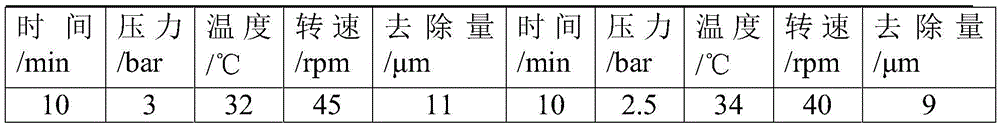

[0055] The process parameters are shown in the table below:

[0056]

[0057] Through the detection, it is concluded that the quality parameters of the 5-inch lightly doped silicon wafer process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com