Control system for servo press

A technology for servo presses and control systems, applied in presses, manufacturing tools, etc., can solve the problems of high control system cost, waste of hardware resources, and high power consumption, and achieve improved system accuracy, enhanced real-time performance, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

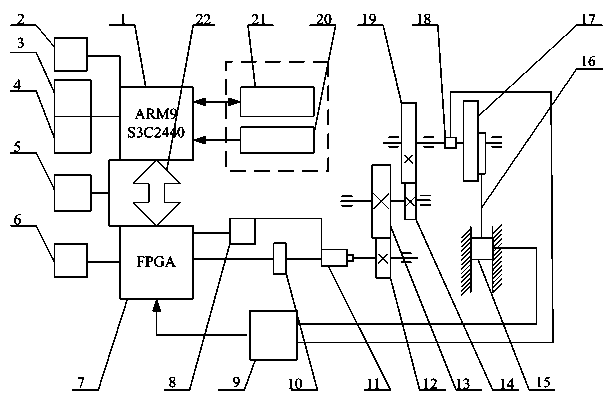

[0013] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

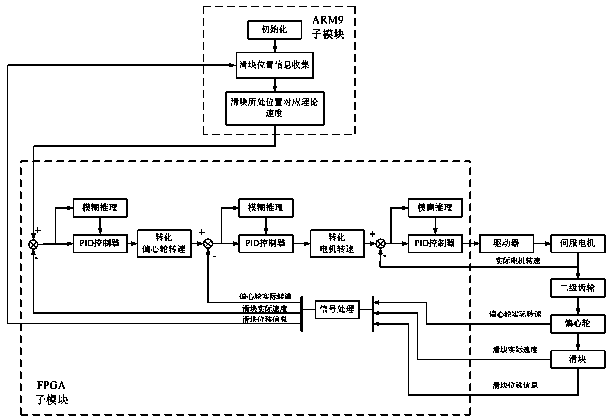

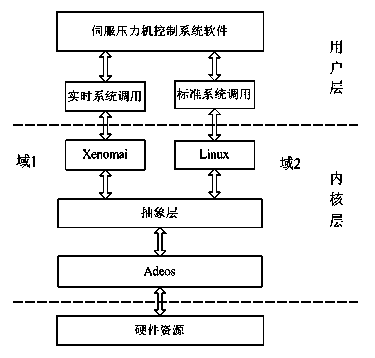

[0014] figure 1 Shown the structure of a preferred embodiment of the present invention, as shown in the figure, the servo press control system of the present invention, take S3C2440 chip 1 as core, take SRAM unit 3, NANDFLASH unit 4 as memory and storage device to form ARM9 microprocessing Device sub-module; the external interface sub-module includes a USB interface, a serial port, and a parallel port, which can be connected with the host machine through the external interface sub-module, so as to facilitate the upgrade of the system in the core board; the operation panel 20 and the touch screen 21 constitute the whole man-machine interface The sub-module realizes the connection with the ARM9 microprocessor sub-module through serial port communication, transmits the user-set parameters to the system, and can display the monitoring screen of the servo pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com