Constantan-oxygen-free copper composite tuning material and preparation method thereof

A technology of oxygen-free copper and constantan alloy, which is applied in the direction of chemical instruments and methods, transit time electron tubes, lamination devices, etc., can solve the problem of poor density on the surface of the coating, poor connection of the coating of the tuning diaphragm, and difficulty in the thickness of the coating. Precise control and other issues, to achieve the effect of bright surface, overcome the weak connection of the coating, and strong anti-fatigue ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

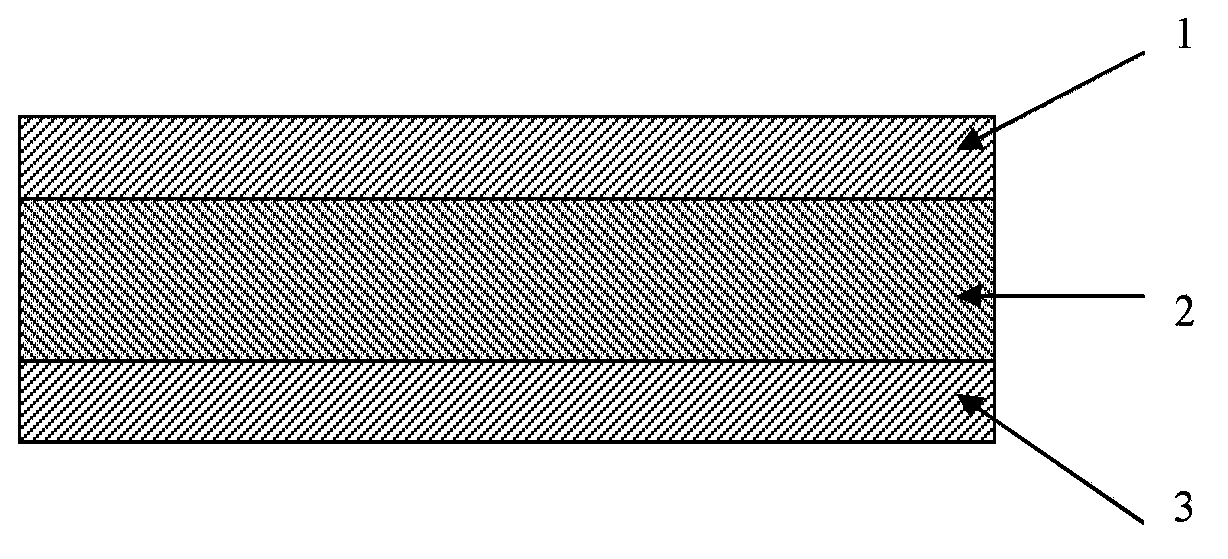

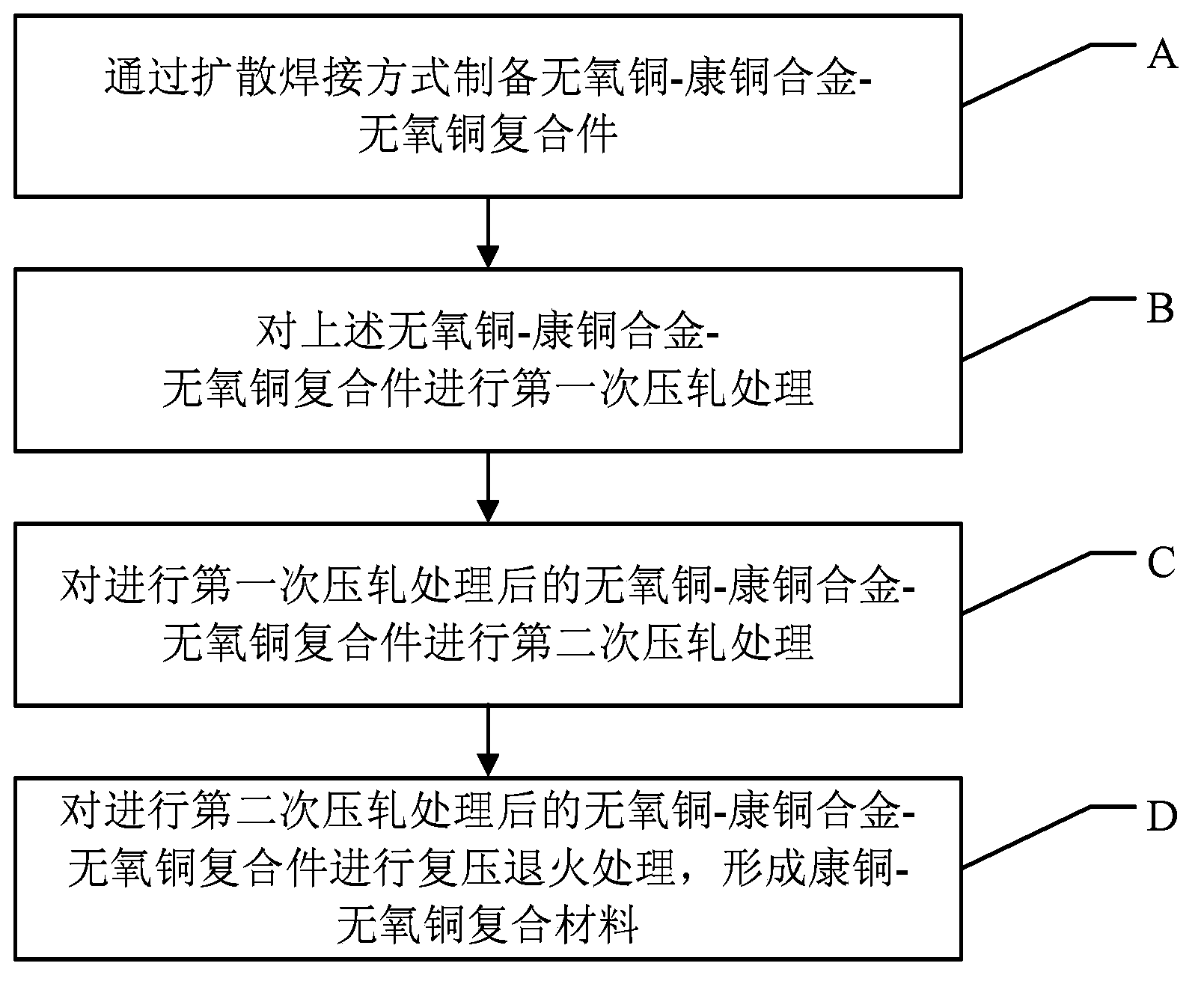

[0024] In yet another exemplary embodiment of the present invention, a method for preparing the above-mentioned constantan-oxygen-free copper composite tuning material is also provided. Please refer to figure 2 , the preparation method comprises:

[0025] Step A, preparing an oxygen-free copper-constantan alloy-oxygen-free copper composite by diffusion welding;

[0026] This step A can further include:

[0027] Sub-step A1, cleaning and degreasing the processed cuboid-shaped upper oxygen-free copper material, constantan alloy material and lower oxygen-free copper material, wherein the upper oxygen-free copper material and the lower oxygen-free copper material have the same thickness, and the constantan The thickness ratio of alloy material and upper oxygen-free copper material is 1:1~4:1;

[0028] Sub-step A2, assembling and positioning the parts in the order of the upper oxygen-free copper material, the constantan alloy material and the lower oxygen-free copper material; ...

specific example

[0038] A specific example is given below: prepare two oxygen-free copper parts with a diameter of 50mm and a thickness of 5mm and one constantan alloy part, perform assembly and positioning in the order of oxygen-free copper-constantan-oxygen-free copper, and conduct diffusion welding in a vacuum furnace. The vacuum degree is not lower than 1.0×10 -3 Pa, diffusion pressure 0.3MPa, diffusion temperature 900°C, diffusion time 180min. After diffusion welding, the parts are cold-rolled to 15% of the parts, and the deformation rate of each rolling is 10% to 15%, and then vacuum annealing is carried out. The annealing temperature is 700°C, the heat preservation is 60min, and the vacuum degree is not lower than 1× 10 -3 Pa, after cooling to room temperature with the furnace, take it out and carry out the second rolling treatment, cold rolling to 0.2mm, the deformation rate of each rolling is 15-20%, and finally carry out re-pressure annealing treatment, the annealing temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com