Three-level interlocking brake system of pneumatic tyre roller

A technology for tire rollers and braking systems, which is applied to hydraulic braking transmissions, motor vehicles, safety devices of power plant control mechanisms, etc. Fast and other problems, to achieve the effect of good operating comfort, protection from premature wear and reliable braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

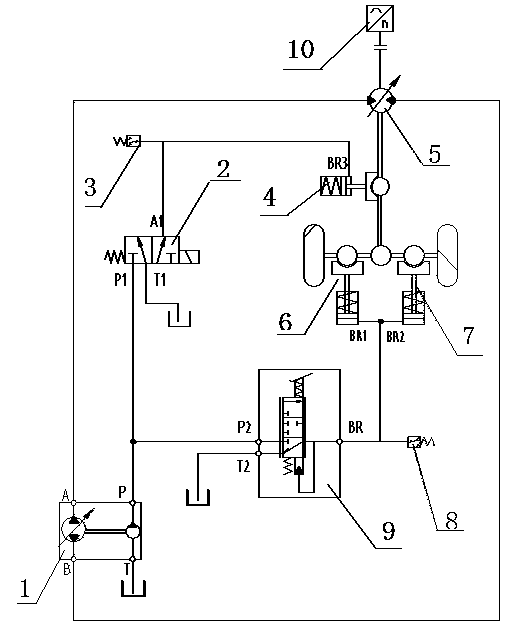

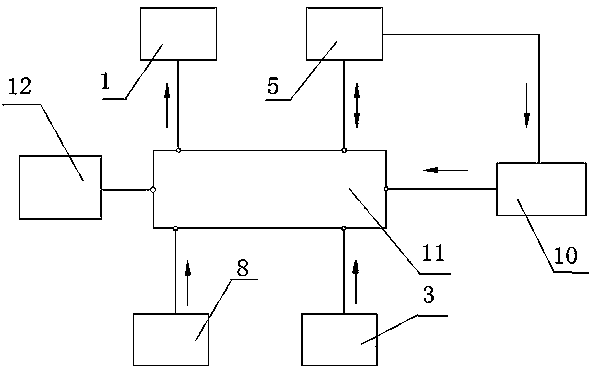

[0033] see figure 1 with figure 2 , the present invention relates to a three-stage interlocking brake system of a tire roller, which are: the handle returns to the middle hydraulic neutral position self-locking brake (hand brake), rear wheel edge brake (pedal brake), rear axle Brakes (parking and emergency braking).

[0034] It includes travel pump 1, emergency brake solenoid valve 2, emergency brake pressure switch 3, drive axle brake 4, drive motor 5, first wheel brake 6, second wheel brake 7, foot brake pressure transmitter 8. Foot brake valve 9, drive motor speed sensor 10, controller 11 and handle 12.

[0035] Port A (first high-pressure oil outlet) and port B (second high-pressure oil outlet) of walking pump 1 are connected to the inlet and outlet of drive motor 5 to form a closed system. Port P of walking pump 1 (charge pump outlet) is connected with the P1 port (oil inlet port) of the emergency brake solenoid valve 2 and the P2 port (oil inlet port) of the foot bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com