Method and apparatus for controlling engine shutdown in hybrid vehicles

A technology for engines and vehicles, which is applied in the layout of multiple different prime movers of hybrid vehicles and general power plants, power plants, etc., can solve problems such as unevenness, noise, vibration, etc., to reduce noise and reduce engine starting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A detailed description of illustrative embodiments of the invention is provided below. The disclosed embodiments are exemplary of the invention, which may be embodied in various and alternative forms. The drawings are not necessarily drawn to scale. Some features can be zoomed in or out to reveal details of a particular part. Specific structural and functional details disclosed in the present invention are not to be interpreted as limiting, but merely as a representative basis for teaching one skilled in the art how to practice the invention.

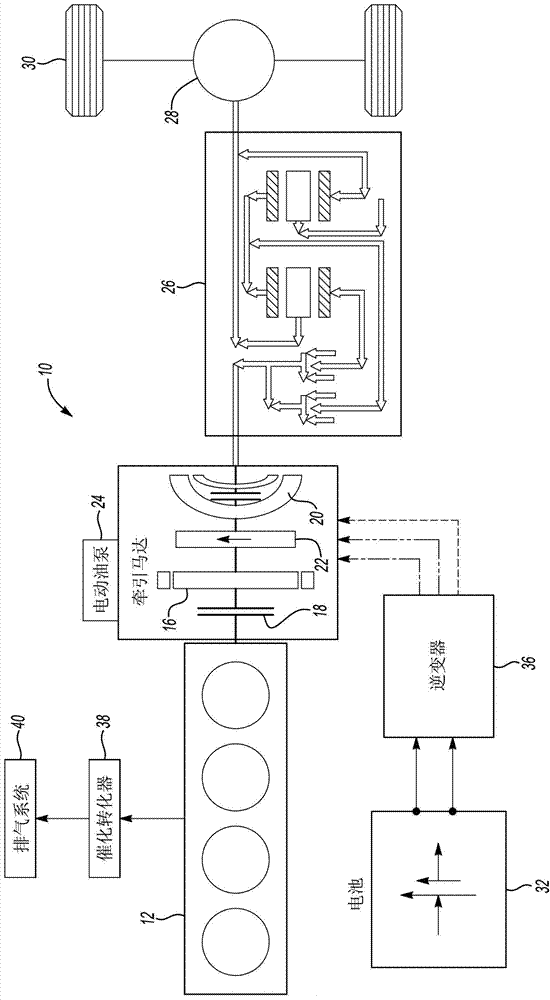

[0042] refer to figure 1 , a hybrid vehicle 10 is schematically illustrated to show the torque flow paths, charging system, and exhaust system. Internal combustion engine 12 and electric machine 16 are selectively coupled to disconnect clutch 18 such that torque may be provided by internal combustion engine 12 , electric machine 16 , or both. The torque converter 20 provides torque from the internal combustion engine 12 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com