Method and device for preparing graphene through processing dry ice by shock waves

A technology of graphene and shock wave, applied in the direction of graphene, nano-carbon, etc., can solve the problems of high cost, complicated process, low cost, etc., and achieve the effect of short time-consuming, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

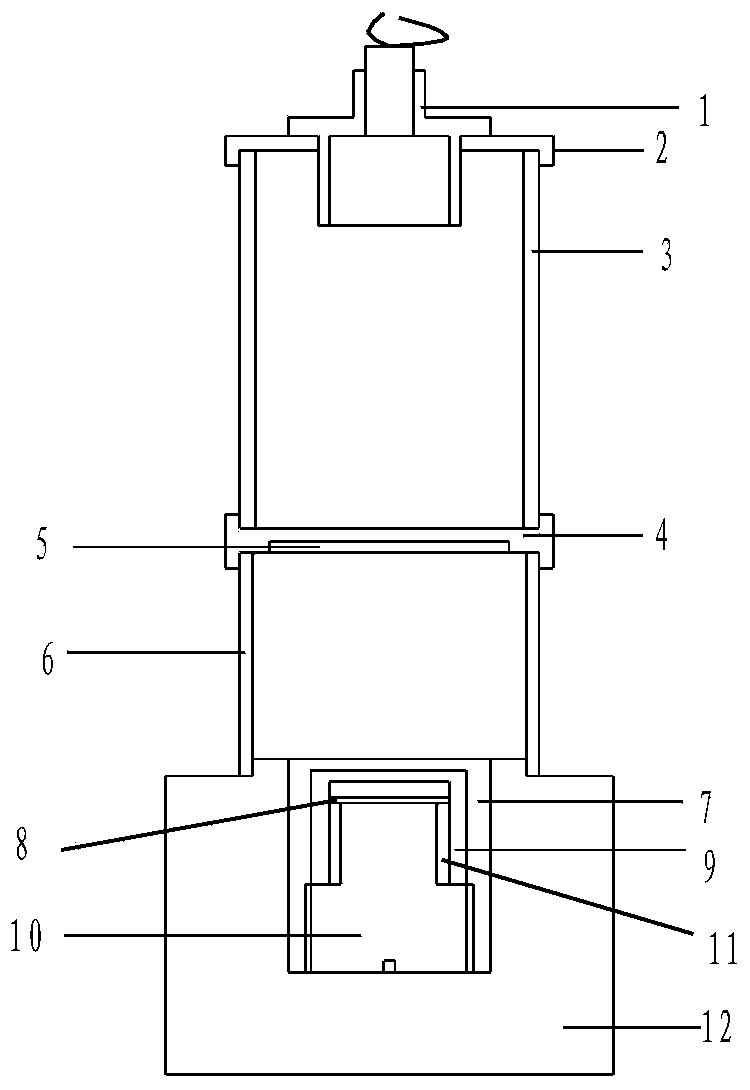

Method used

Image

Examples

Embodiment 1

[0052] Dry ice and calcium hydride are selected as the precursor material, and the dry ice and calcium hydride are uniformly mixed at a mass ratio of 3:1 to make a powder raw material, and the powder raw material is pressed into a shock wave synthesis graphene device to form a preform, and the preform is The density is 60%. The nitromethane liquid explosive detonation is used to drive the stainless steel flyer to hit the stainless steel sample box at high speed to generate instantaneous high temperature and high pressure for the shock wave synthesis of graphene, and the sample is recovered and cleaned.

[0053] The charge height of the nitromethane liquid explosive is 130mm, the material of the flyer is stainless steel, and the thickness of the flyer is 2mm. The speed loss of the flyer during flight is negligible. The calculation shows that the speed of the flyer hitting the sample box is 2.87km / s.

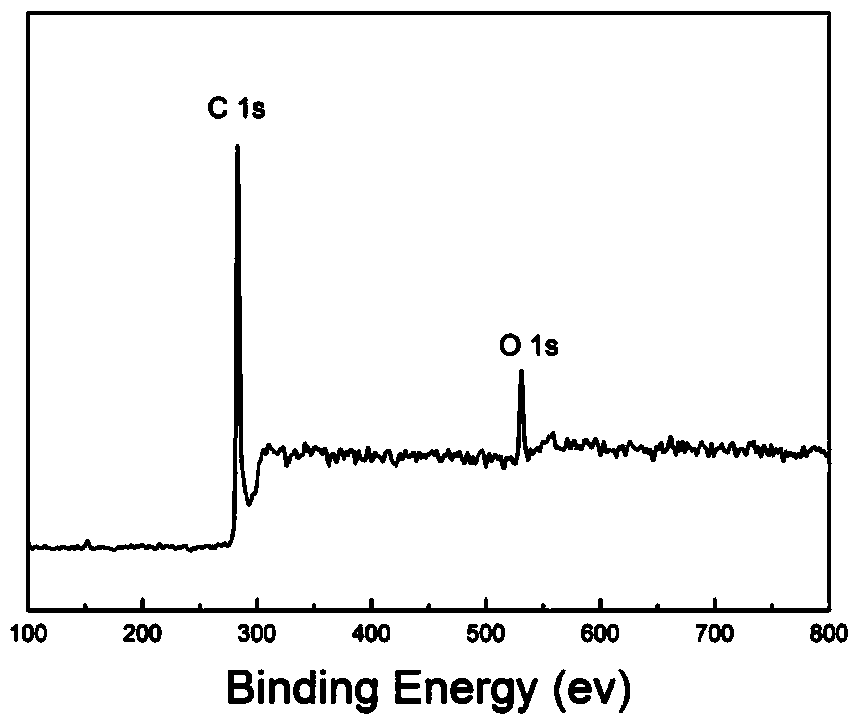

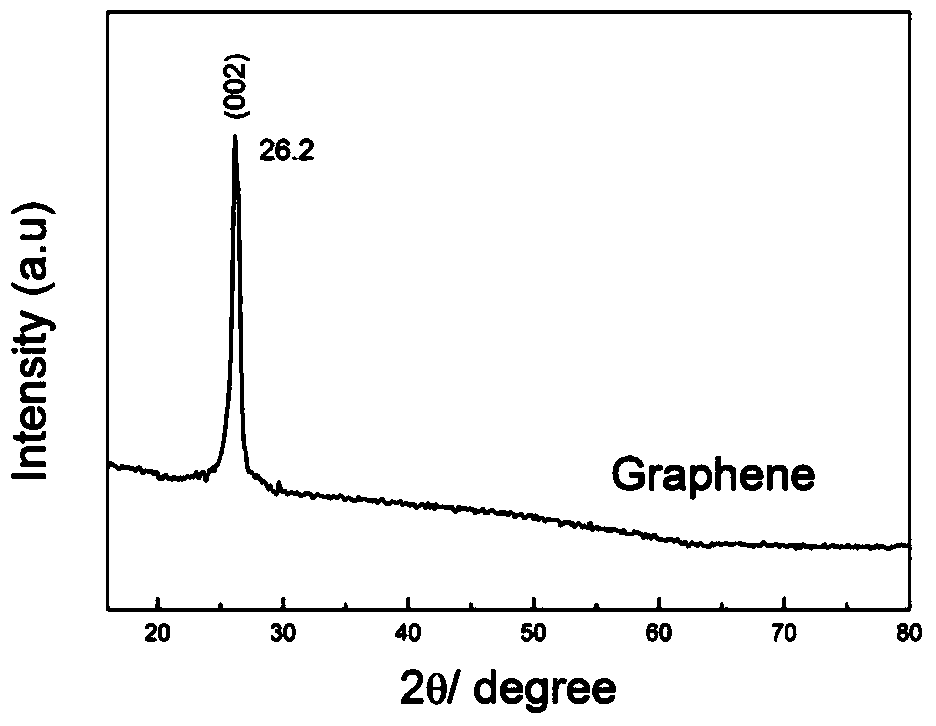

[0054] For the XPS spectrum of the experimental product, see figure 2 , XRD...

Embodiment 2

[0056] Dry ice and calcium hydride are selected as the precursor material, and the dry ice and calcium hydride are uniformly mixed at a mass ratio of 4:1 to make a powder raw material, and the powder raw material is pressed into a shock wave synthesis graphene device to be pressed into a blank, and the blank is dense. 70%. The nitromethane liquid explosive detonation is used to drive the stainless steel flyer to hit the stainless steel sample box at high speed to generate instantaneous high temperature and high pressure for the shock wave synthesis of graphene, and the sample is recovered and cleaned.

[0057] The charge height of the nitromethane liquid explosive is 100mm, the flyer material is stainless steel, and the thickness of the flyer is 2mm. The speed loss of the flyer during the flight is negligible, and the calculation shows that the speed of the flyer hitting the sample box is 2.58km / s.

[0058] From the XPS spectrum of the experimental product, it can be seen tha...

Embodiment 3

[0061] Dry ice and calcium hydride are selected as the precursor material, and the dry ice and calcium hydride are uniformly mixed at a mass ratio of 2:1 to make a powder raw material, and the powder raw material is pressed into a shock wave synthesis graphene device to be pressed into a preform, and the preform has a high density. 70%. The nitromethane liquid explosive detonation is used to drive the stainless steel flyer to hit the stainless steel sample box at high speed to generate instantaneous high temperature and high pressure for the shock wave synthesis of graphene, and the sample is recovered and cleaned.

[0062] The charge height of the nitromethane liquid explosive is 150mm, the material of the flyer is stainless steel, and the thickness of the flyer is 2mm. The speed loss of the flyer during the flight is negligible, and the calculation shows that the speed of the flyer hitting the sample box is 3.07km / s.

[0063] From the XPS spectrum of the experimental produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com