Method for treating and utilizing coal gasification wastewater

A coal gasification wastewater purification treatment technology, applied in the field of water treatment, can solve the problems of lack of economical and effective emission reduction measures, and achieve the effects of resource utilization, carbon dioxide emission reduction, and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] This embodiment is used to illustrate the treatment and utilization method of coal gasification wastewater provided by the present invention.

[0093] (1) Biochemical treatment:

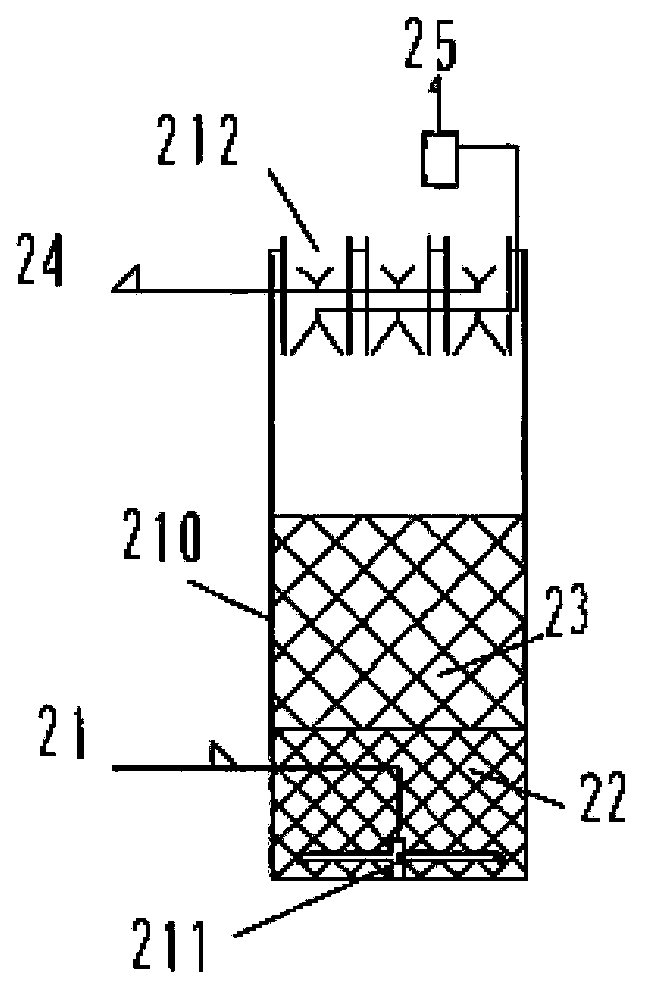

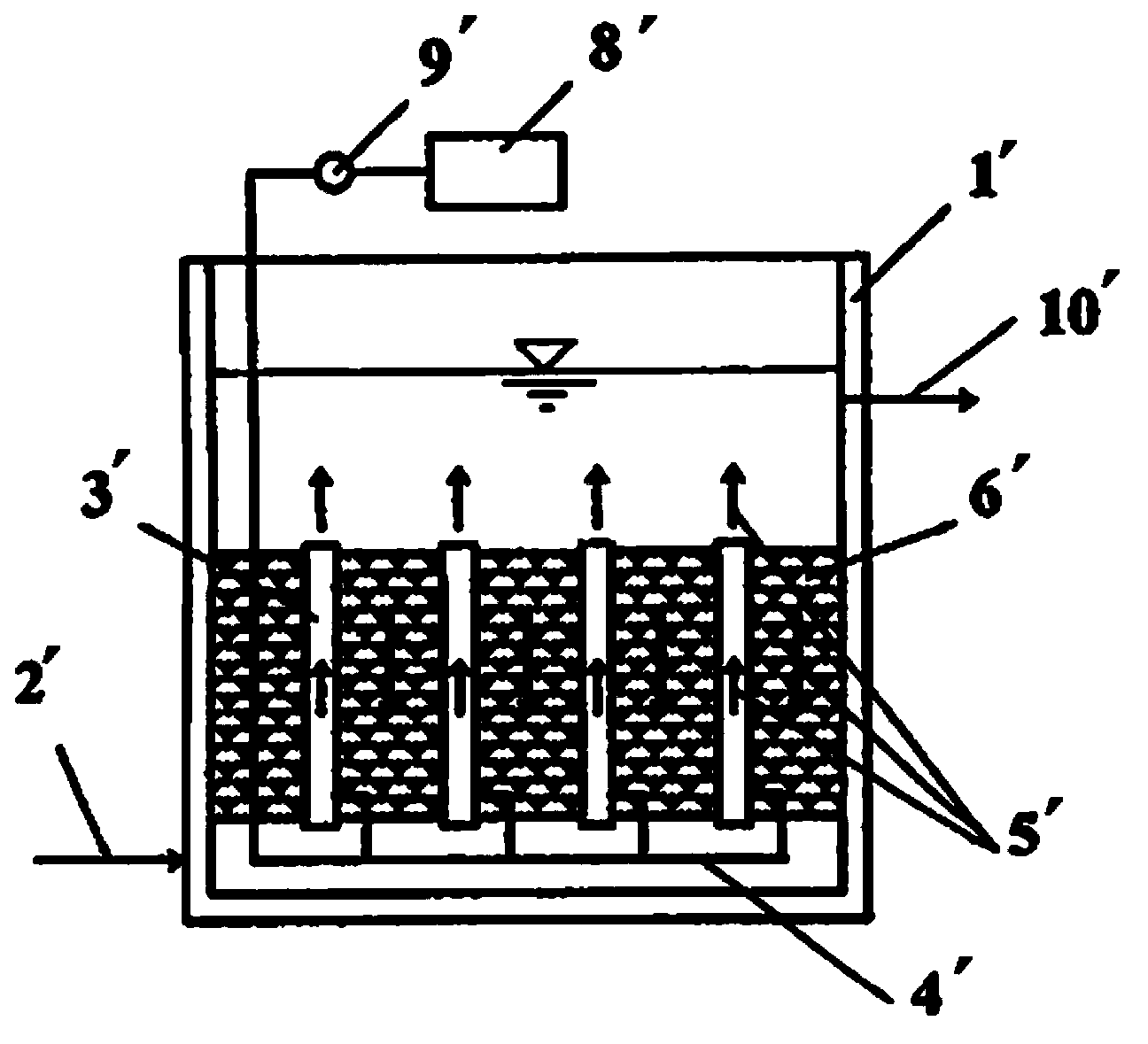

[0094] Biochemical treatment includes sequential anaerobic biological treatment and aerobic biological treatment, wherein, the anaerobic biological treatment is figure 1 Carried out in the shown anaerobic sludge expanded bed reactor, the sludge concentration in the acid-producing bacteria accumulation area 22 and the methanogen accumulation area 23 is 30g / L, and the high 18m of described anaerobic sludge expanded bed reactor, The diameter is 14m, the height of the acid-producing bacteria gathering area 22 is 4.2m, and the height of the methanogenic bacteria gathering area 23 is 8.4m. The aerobic biological treatment in figure 2 Carried out in the shown aerobic biofilm reactor, wherein, the sludge concentration is 5g / L;

[0095] Under the conditions of a temperature of 34°C and a pH value o...

Embodiment 2

[0105] This embodiment is used to illustrate the treatment and utilization method of coal gasification wastewater provided by the present invention.

[0106] (1) Biochemical treatment:

[0107] Biochemical treatment includes sequential anaerobic biological treatment and aerobic biological treatment, wherein, the anaerobic biological treatment is figure 1 The anaerobic sludge expanded bed reactor shown is carried out, wherein, the sludge concentration in the acid-producing bacteria accumulation area 22 and the methanogen accumulation area 23 is 10g / L, and the described anaerobic sludge expanded-bed reactor is high The height of the acid-producing bacteria gathering area 22 is 4.8 m, and the height of the methanogenic bacteria gathering area 23 is 8.4 m. The aerobic biological treatment in figure 2 Carried out in the shown aerobic biofilm reactor, wherein, the sludge concentration is 4g / L;

[0108] Under the conditions of a temperature of 37°C and a pH value of 7, the pretre...

Embodiment 3

[0118] This embodiment is used to illustrate the treatment and utilization method of coal gasification wastewater provided by the present invention.

[0119] (1) Biochemical treatment:

[0120] Biochemical treatment includes sequential anaerobic biological treatment and aerobic biological treatment, wherein, the anaerobic biological treatment is figure 1 Carried out in the shown anaerobic sludge expanded bed reactor, the sludge concentration in the acid-producing bacteria accumulation area 22 and the methanogen accumulation area 23 is 50g / L, and the high 18m of described anaerobic sludge expanded bed reactor, The height of the acid-producing bacteria gathering area 22 is 4.8m, and the height of the methanogenic bacteria gathering area 23 is 9.6m. The aerobic biological treatment in figure 2 Carried out in the shown aerobic biofilm reactor, wherein, the sludge concentration is 3g / L;

[0121] Under the conditions of a temperature of 36°C and a pH value of 8, the pretreated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com