Catalyst component for ethylene polymerization reaction and catalyst

A technology of ethylene polymerization and catalyst, which is applied in the field of preparation of the catalyst component, can solve the problem of high fine powder content, etc., and achieve the effects of less fine powder content, simple preparation process and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

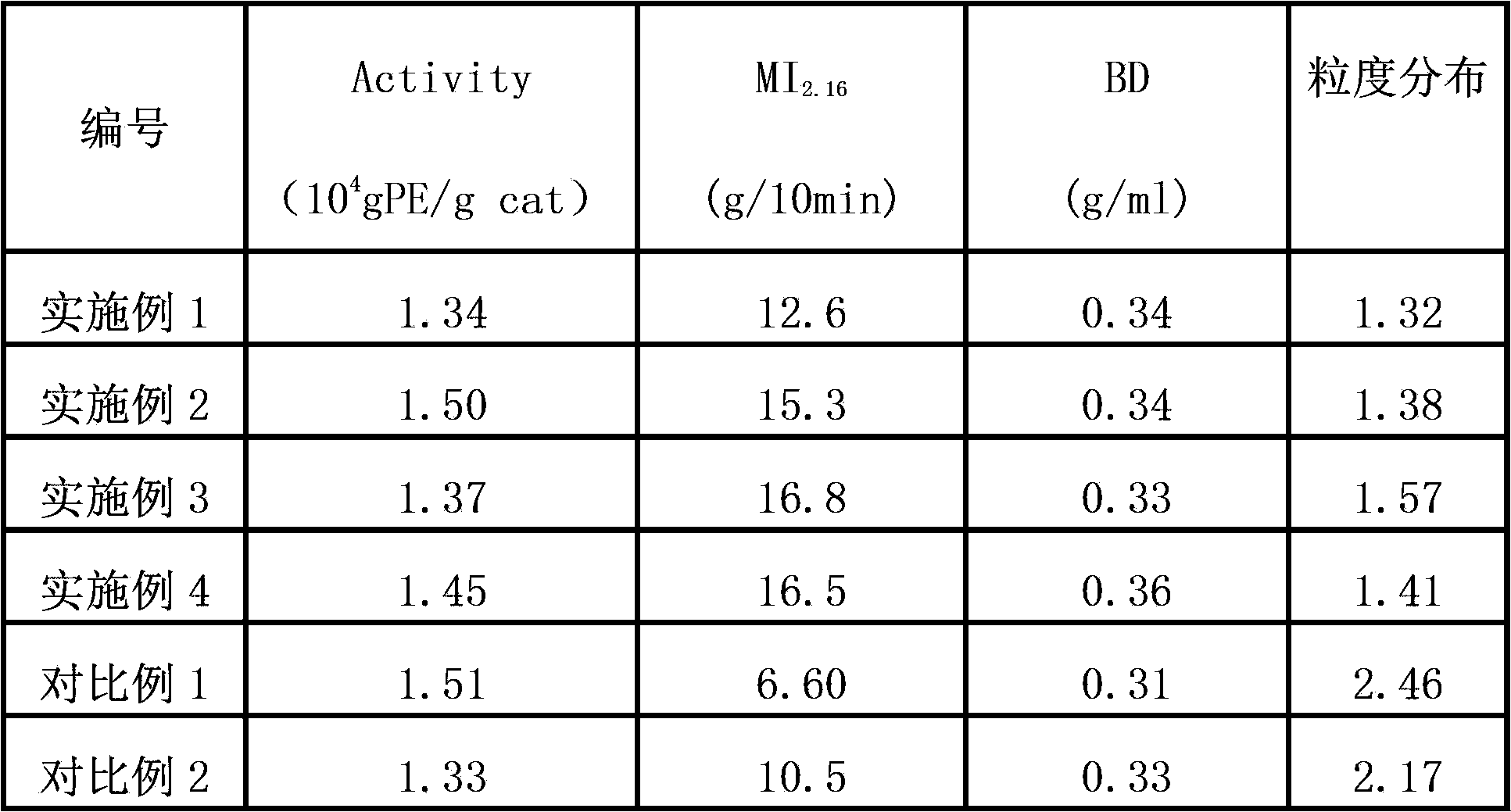

Examples

Embodiment 1

[0047] (1) Weigh 24g of magnesium dichloride, add 195ml of tetrabutyl titanate, heat up to 140°C and stir to react until a transparent solution is formed. After the solution is cooled to close to room temperature, add 180ml of toluene, stir and mix evenly, and take out the obtained solution for later use.

[0048] (2) Take 10 ml of the solution obtained in step (1), add 20 ml of hexane to dilute, add 1.0 ml of isoamyl acetate, and stir at room temperature for 1 hour.

[0049] (3) Slowly add 10.5 ml of 3.0M dichloroethylaluminum solution to the reaction product in the second step with a constant pressure dropper at room temperature. After the addition is completed, raise the bath temperature to 45°C for 1 hour. The reaction was stirred at 60° C. for 4 hours to obtain a catalyst component suspension.

[0050] (4) Lower the temperature of the catalyst component suspension to room temperature, let it stand still, settle for 30 minutes, wash three times with hexane, the amount of h...

Embodiment 2

[0053] Change 1.0 milliliters of isoamyl acetate in the catalyst preparation step (2) to 0.5 milliliters, and other conditions are the same as in Example 1.

[0054] The evaluation conditions for the slurry polymerization of the catalyst are the same as in Example 1, and the polymerization results are shown in Table 1.

Embodiment 3

[0056] Change 1.0 milliliters of isoamyl acetate in the catalyst preparation step (2) to 0.2 milliliters, and other conditions are the same as in Example 1.

[0057] The evaluation conditions for the slurry polymerization of the catalyst are the same as in Example 1, and the polymerization results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com