Formula for producing polyurethane material with uniform bubbles and high air permeability and fabrication technology thereof

A polyurethane material and manufacturing process technology, applied in the field of polyurethane materials, can solve the problems of disordered cell structure, skin infection, excessive sweat secretion, etc., and achieve the effect of reducing bacterial proliferation, tidy cell structure, and avoiding excessive heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

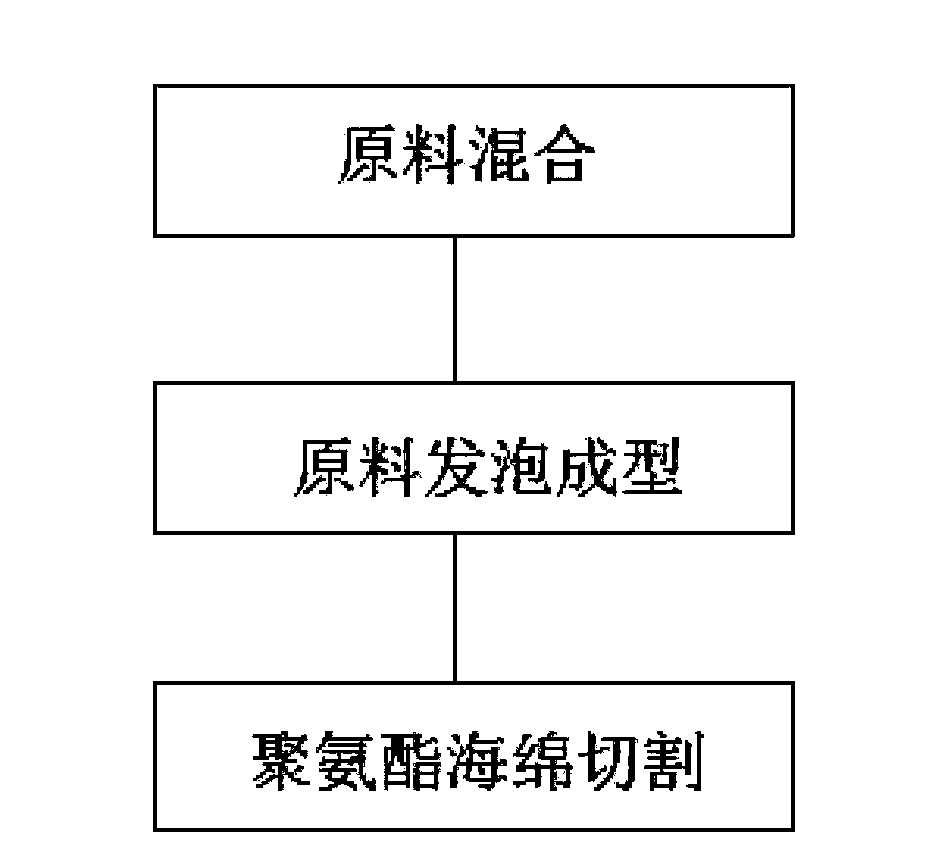

Method used

Image

Examples

Embodiment 1

[0026] Put 10-30 parts of isocyanate, 50-65 parts of polyether polyol, 1 part of water, 1 part of silicone oil, 1.5 parts of foaming agent, 0.8 part of antibacterial agent, 0.05 part of tin, and 2 parts of other additives into the The working storage tank is used for high-speed stirring, and the stirring speed is 3000~6000r / min, which can be adjusted step by step.

[0027] When it is put into the working storage tank for high-speed stirring to form a raw material mixture, the temperature in each working storage tank is controlled within the range of 18-20°C, and the fluctuation range should be less than 1°C. The raw material is sprayed from the working storage tank into the foaming room filled with nitrogen through the foamer. When foaming, the nozzle of the foamer swings at a constant speed, and the raw material mixture is evenly sprayed on the lining paper laid in the foaming room through the hose. , so that the raw material mixture is foamed, and the foaming time is control...

Embodiment 2

[0029] Mix 31-45 parts of isocyanate, 35-45 parts of polyether polyol, 15-30 parts of polymer polyol, 2 parts of water, 1.5 parts of silicone oil, 5 parts of foaming agent, 1 part of antibacterial agent, 0.5 part of tin, and other additives The 3 parts of the agent are respectively put into the working storage tank with a metering pump, and stirred at a high speed. The stirring speed is 3000~6000r / min, which can be adjusted in stages.

[0030] When it is put into the working storage tank for high-speed stirring to form a raw material mixture, the temperature in each working storage tank is controlled within the range of 21-25°C, and the fluctuation range should be less than 1°C. The raw material is sprayed from the working storage tank into the foaming room filled with nitrogen through the foamer. When foaming, the nozzle of the foamer swings at a constant speed, and the raw material mixture is evenly sprayed on the lining paper laid in the foaming room through the hose. , so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com