Hydroprocessing method for producing high quality solvent oil

A technology for hydrotreating and solvent oil, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems such as the difficulty in producing food-grade solvent oil products, and achieve the omission of high-pressure gas stripping facilities and reduce equipment costs , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

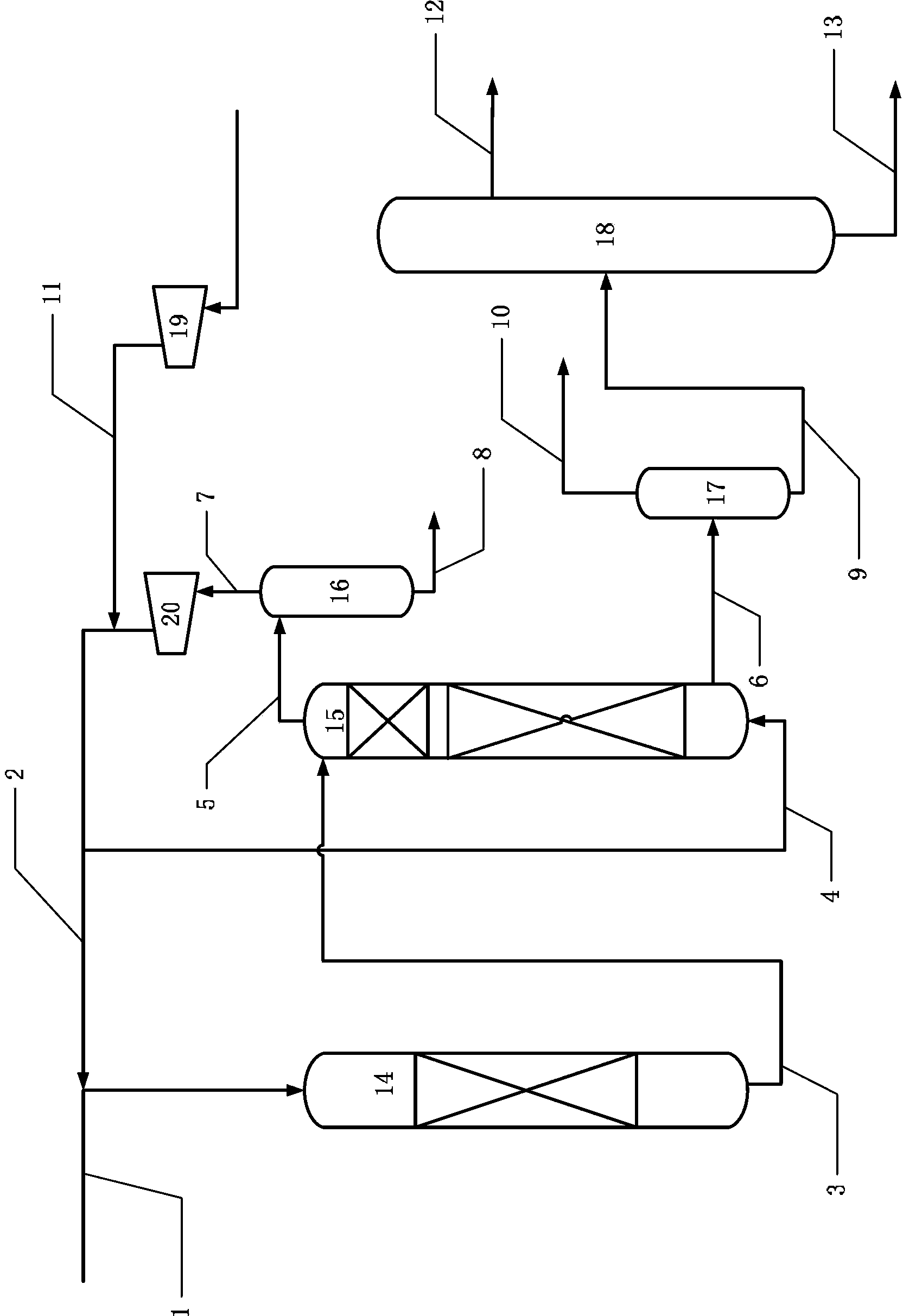

[0038] The raw material oil A is first fully mixed with hydrogen, enters the first reaction zone, and at a relatively high reaction temperature, it contacts with the non-noble metal hydrogenation catalyst I (Cat-A) to carry out deep hydrodesulfurization reaction, denitrogenation reaction and partial aromatics Saturation reaction; the reaction product enters the second reaction zone, and under the action of non-noble metal hydrotreating catalyst II (Cat-A) and noble metal hydrotreating catalyst (Cat-B), it is countercurrently contacted with hydrogen to continue deep aromatics saturation For the reaction, the loading volume ratio of the non-noble metal hydrotreating catalyst II and the noble metal hydrotreating catalyst is 1:7. At the same time, the second reactor has the effect of a stripping tower, which can remove hydrogen sulfide and ammonia in the raw material. After the reaction product at the top of the second reaction zone is cooled and separated, the hydrogen-rich gas ob...

Embodiment 2

[0040] The raw material oil A is first fully mixed with hydrogen, enters the first reaction zone, and contacts with the non-precious metal hydrotreating catalyst I (Cat-A) at a relatively high reaction temperature to carry out deep hydrodesulfurization reaction, denitrogenation reaction and partial aromatics saturation Reaction; the reaction product enters the second reaction zone, under the action of non-precious metal hydrotreating catalyst II (Cat-A) and noble metal hydrotreating catalyst (Cat-B), it is in countercurrent contact with hydrogen to continue the deep aromatic saturation reaction , the loading volume ratio of non-precious metal hydrotreating catalyst II and noble metal hydrotreating catalyst is 1:5. At the same time, the second reactor has the effect of a stripping tower, which can remove hydrogen sulfide and ammonia in the raw material. The reaction product at the top of the second reaction zone is cooled, and the hydrogen-rich gas obtained is recycled hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com