A Two-Stage Dissolved Oxygen Control Method for Improving the Production of Spinosad

A spinosad and stage technology, applied in the fields of fermentation engineering and biopharmaceuticals, can solve the problems of stages and control of dissolved oxygen of Saccharopolyspora spinosa that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

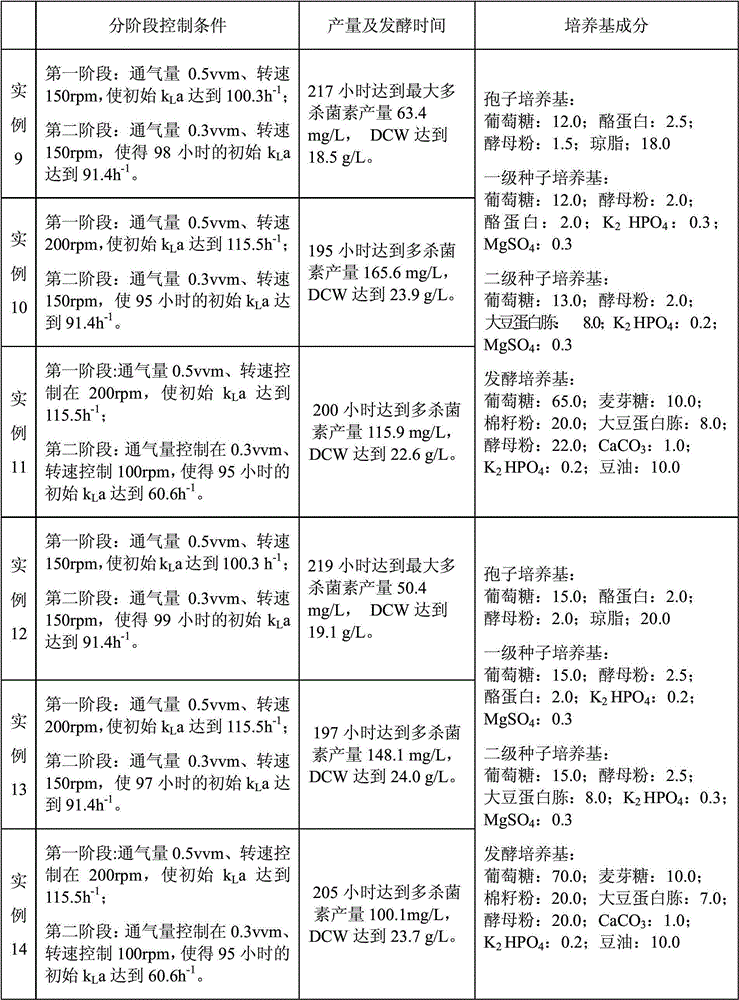

Examples

Embodiment 1

[0031] A kind of two-stage dissolved oxygen control method provided by the invention improves spinosad output, and its specific steps are as follows:

[0032] 1. Spore Preparation of S. spinosa

[0033] The freeze-dried powder in the freeze-drying tube of S. spinosa was transferred into the slant medium, and activated at 28° C. for 10 days to obtain Saccharopolyspora spinosa spores.

[0034] The slant medium per liter (unit: gram / liter) contains glucose: 10.0; casein: 2.0; yeast powder: 1.0; agar: 15.0.

[0035] 2. Preparation of Primary Seed Solution of Saccharopolyspora spinosa

[0036] Inoculate the S. spinosa spores obtained in step 1 into the S. spinosa primary seed medium, and culture at 30° C. for 72 hours to obtain the S. spinosa primary seed liquid.

[0037] Described per liter primary seed culture medium (unit: gram / liter) contains glucose: 10.0; Yeast powder: 2.0; Casein: 2.0; K 2 HPO 4 : 0.2; MgSO 4 : 0.3.

[0038] 3. Secondary Seed Liquid Preparation of Sacc...

Embodiment 2

[0046] The composition and inoculum size of slant medium, primary seed medium, secondary seed medium, and fermentation medium are the same as in Example 1.

[0047] The control conditions of the fermentation process: at the beginning of the fermentation, the ventilation volume is controlled at 0.5vvm, and the rotation speed is controlled at 200rpm, so that the initial k L a reached 115.5h -1 ; Fermentation 96 hours thalline growth enters logarithmic growth terminal stage, from 96 hours to the end of fermentation, the ventilation volume is controlled at 0.3vvm, and the rotating speed is controlled at 150rpm, so that the initial k of 96 hours L a reached 91.4h -1 , the two-stage dissolved oxygen control made the production of spinosyn reach 160.9mg / L in 196 hours, and the DCW reached 24.1g / L.

Embodiment 3

[0049] The composition and inoculum size of slant medium, primary seed medium, secondary seed medium, and fermentation medium are the same as in Example 1.

[0050] The control conditions of the fermentation process: at the beginning of the fermentation, the ventilation volume is controlled at 0.7vvm, and the rotation speed is controlled at 150rpm, so that the initial k L a reached 110.1h -1 ; Fermentation 98 hours thalline growth enters logarithmic growth terminal stage, from 98 hours to the end of fermentation, the ventilation volume is controlled at 0.3vvm, and the rotating speed is controlled at 150rpm, so that the initial k of 98 hours L a reached 91.4h -1 , the two-stage dissolved oxygen control made spinosad production reach 70.1mg / L in 215 hours, and DCW reached 21.9g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com