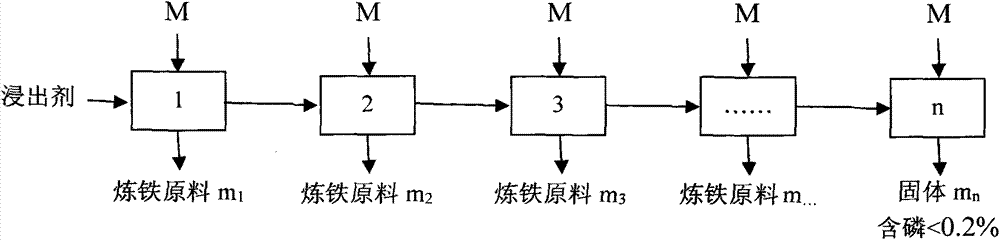

Method for removing phosphorus and leaching iron from high-phosphorus oolitic hematite through cross flow

A technology for high-phosphorus oolites and hematites, which is applied in the field of cross-flow leaching of high-phosphorus oolitic hematites for iron-rich dephosphorization, can solve the problems of difficulty in effectively improving ore grades, large environmental pollution, and high acidity of wastewater, and can reduce iron The effect of high content, large processing capacity and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1. use tap water and concentrated hydrochloric acid preparation concentration to be the hydrochloric acid solution of 2.5mol / L as leaching agent, at liquid-solid ratio 3: 1, normal temperature, under the condition of rotating speed 300r / min, add particle size below 0.147mm, total iron content is 49%, 50 g of high-phosphorus oolitic hematite powder with a phosphorus content of 1.125%, stirred for 45 minutes, filtered after stopping the stirring, and obtained ironmaking raw material 1 and filtrate 1, the total iron content of raw material 1 was 58.3% and the phosphorus content was 0.086%; Using filtrate 1 as leaching agent, add the same amount of high-phosphorus oolitic hematite powder under the same conditions as above, stir for 45 minutes, stop stirring and filter to obtain ironmaking raw material 1' and filtrate 1', the total iron content of raw material 1' 59.1% and phosphorus content 0.127%; use filtrate 1' as the leaching agent to repeat the operation of f...

Embodiment 2

[0023] Embodiment 2. use tap water and concentrated hydrochloric acid preparation concentration to be the hydrochloric acid solution of 2.5mol / L as leaching agent, at liquid-solid ratio 3: 1, normal temperature, under the condition of rotating speed 250r / min, add particle size below 0.147mm, total iron content is 52.4%, 50 g of high-phosphorus oolitic hematite powder with a phosphorus content of 0.82%, stirred for 45 minutes, filtered after stopping the stirring, and obtained ironmaking raw material 2 and filtrate 2, the total iron content of raw material 2 was 60.8% and the phosphorus content was 0.086%; Using the filtrate 2 as the leaching agent, add the same amount of high-phosphorus oolitic hematite powder under the same conditions as above, stir for 45 minutes, stop stirring and filter, and then obtain the ironmaking raw material 2' and filtrate 2', the total iron content of the raw material 2' 61.5% and phosphorus content 0.127%; repeat the operation of filtrate 2 with fi...

Embodiment 3

[0024] Embodiment 3. use tap water and concentrated hydrochloric acid preparation concentration to be the hydrochloric acid solution of 2.0mol / L as leaching agent, at liquid-solid ratio 3: 1, normal temperature, under the condition of rotating speed 250r / min, add particle size and be less than 0.147mm, total iron content is 46%, 50 g of high-phosphorus oolitic hematite powder with a phosphorus content of 0.82%, stirred for 45 minutes, filtered after stopping the stirring, and obtained ironmaking raw material 3 and filtrate 3, the total iron content of raw material 3 was 51.5% and the phosphorus content was 0.090%; Using the filtrate 3 as the leaching agent, add the same amount of high-phosphorus oolitic hematite powder under the same conditions as above, stir for 45 minutes, stop stirring and then filter to obtain the ironmaking raw material 3' and filtrate 3'. The ironmaking raw material 3' has a total iron content of 53.2%, a phosphorus content of 0.133%, and two leaching sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com