Method for maintaining morphology of ADN (ammonium dinitramide) spherical particle

A technology of ammonium dinitramide and spheroidization, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of storage and propellant production process inconvenience, and achieve easy implementation and promotion, and simple operation , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

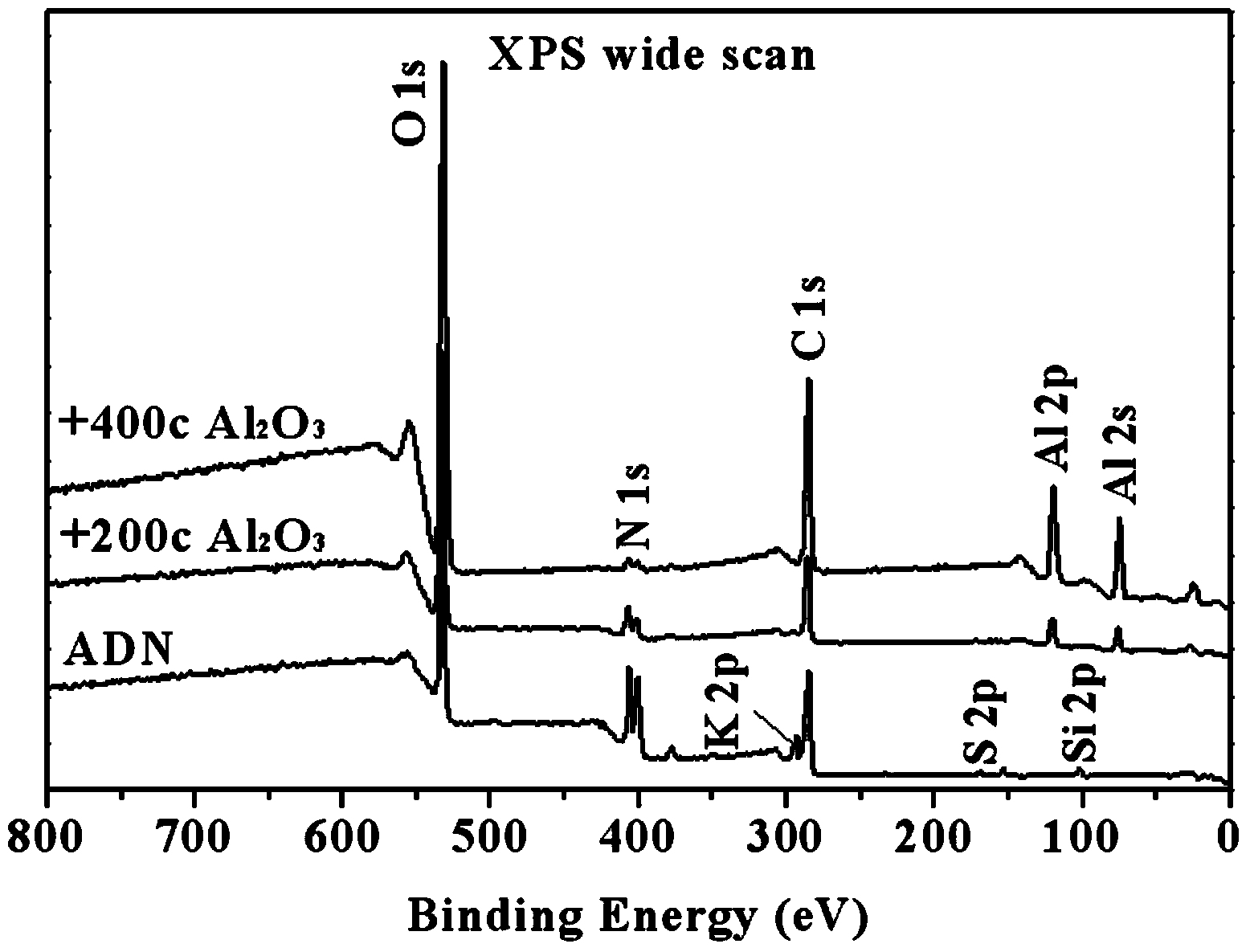

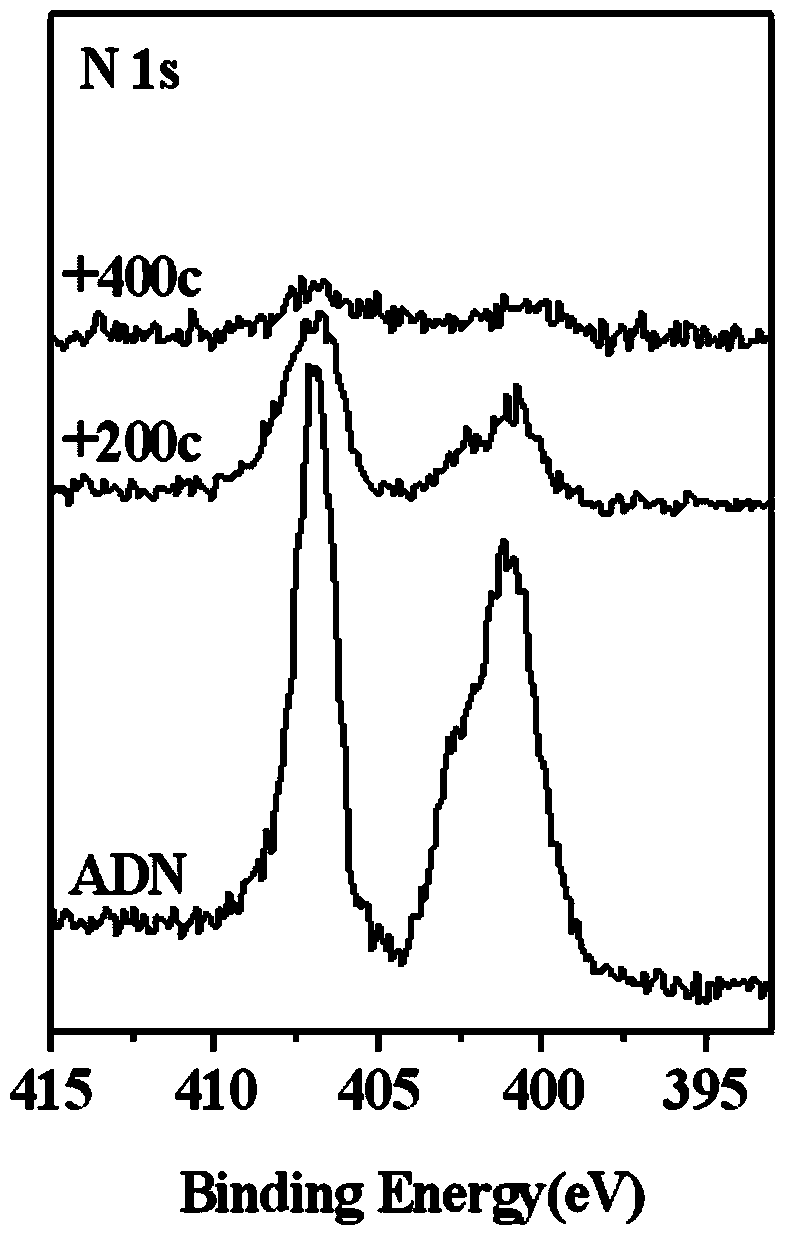

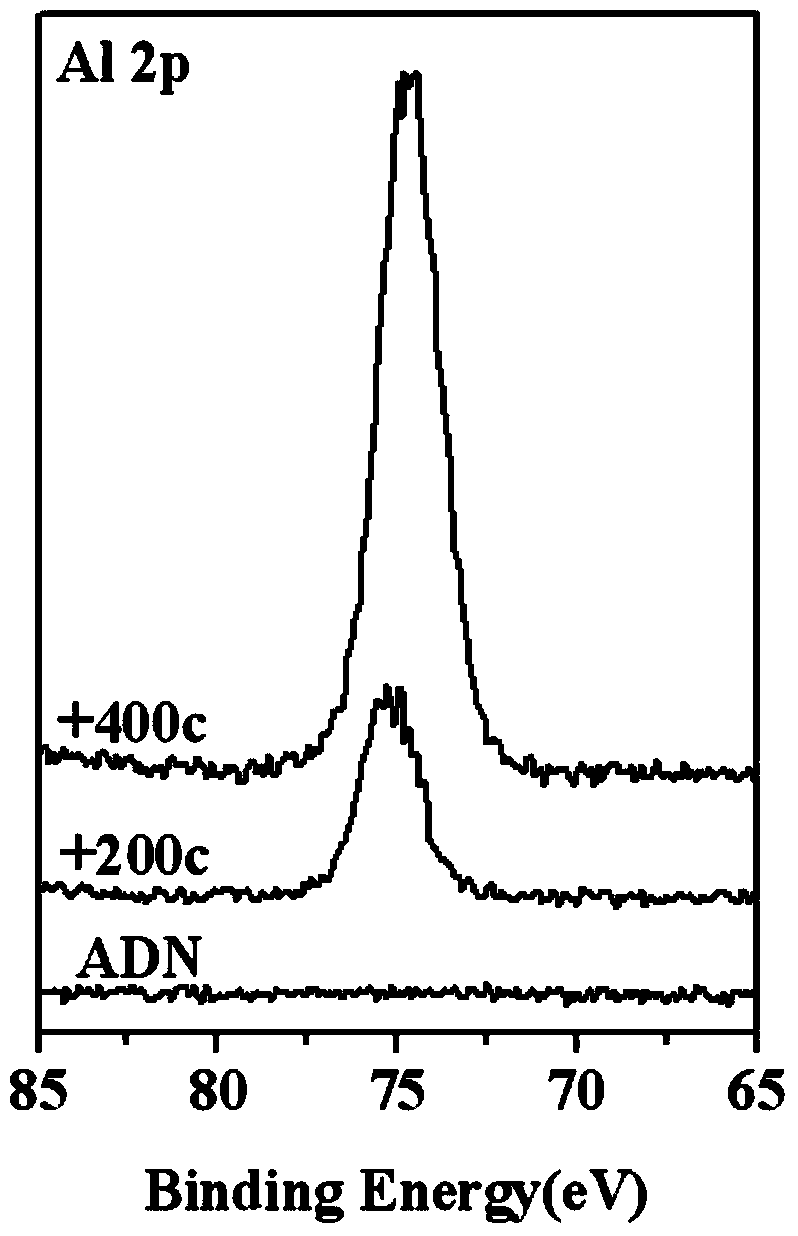

[0047] This example provides a method for maintaining the structure and morphology of ammonium dinitramide (ADN) spheroidized particles. The method specifically includes the following steps:

[0048] Step 1: Place the ADN spheroidized particle sample in the reaction chamber of the vapor phase atomic layer deposition system, seal the reaction chamber, feed nitrogen gas into the vapor phase atomic layer deposition system and vacuumize it, adjust the flow rate of nitrogen gas to 80 sccm, and adjust the outlet valve of the reaction chamber so that The pressure in the chamber is controlled at 133Pa; and the sample temperature is kept at 55°C by heating;

[0049] Step 2: Perform atomic layer deposition on the ADN spheroidized particle sample to form a coating film. A cycle of atomic layer deposition growth includes the following four links:

[0050] (1) Inject the first reaction precursor trimethylaluminum (TMA) into the reaction chamber to make it undergo a saturated surface chemic...

Embodiment 2

[0063] This embodiment provides a method for maintaining the morphology of ADN spheroidized particles. This method is the same as in Embodiment 1, the only difference is that in step 3 of this embodiment, step 2 needs to be repeated for 400 cycles. Atomic layer deposition was carried out on the ADN spheroidized particles, and a coating film with a thickness of 45nm was formed on the surface of the ADN spheroidized particles, so that the coating film content was 0.1% of the total weight of the ADN spheroidized particles after coating, and the average film growth of the coating film The rate is 0.11 nm / cycle, and the shape of the ADN spheroidized particles is maintained by the coating film.

[0064] The ADN spheroidized particles treated with 400 cycles of ALD alumina coating in this example have no obvious change in the shape of the sample after being placed in humid air (temperature 23 °C, humidity 70%) for 48 hours, as shown in Figure 10 shown. Figure 9 It is the topograph...

Embodiment 3

[0072] This embodiment provides a method for maintaining the morphology of ADN spheroidized particles. This method is the same as in Embodiment 1, the only difference is that in step 3 of this embodiment, step 2 needs to be repeated for 800 cycles. Atomic layer deposition was carried out on the ADN spheroidized particles, and a coating film with a thickness of 90nm was formed on the surface of the ADN spheroidized particles, so that the coating film content was 0.2% of the total weight of the ADN spheroidized particles after coating, and the average film growth of the coating film The rate is 0.11 nm / cycle, and the shape of the ADN spheroidized particles is maintained by the coating film.

[0073] The morphology of the ADN spheroidized particles treated with 800 cycles of ALD alumina coating in this example did not change significantly after being placed in humid air (temperature 23°C, humidity 70%) for 48 hours.

[0074] It can be seen from the above examples 1 to 3 that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com