A nepe propellant burning rate inhibitor

A propellant and inhibitor technology, applied in the field of amide organic compound type NEPE propellant burning rate inhibitor, can solve the problems of difficulty, low burning rate, narrow adjustable range of burning rate, etc., to reduce the burning rate, expand the Application field, the effect of expanding the adjustable range of burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

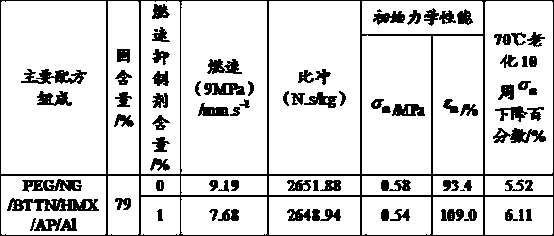

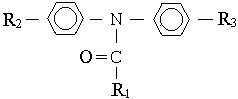

[0019] The static burning rate of the propellant bar added with NEPE propellant burning rate inhibitor, the burning rate test method is the underwater acoustic emission method. Table 1 shows the composition of the NEPE propellant formula and the added burning rate inhibitor in the molecular formula R 1 , R 2 , R 3 The groups are 2-phenylbutyl, 2-phenylpropyl and ethyl, respectively. Table 1 shows the comparison of the energy performance, mechanical performance and storage performance of the propellant before and after adding the burning rate depressant. in FIG. 1 , , , are the maximum tensile strength of the propellant in uniaxial tension, the elongation corresponding to the maximum tensile strength, the elongation at break and the initial modulus, respectively. Table 2 and Table 3 show the changes in the burning rate when different amounts of the burning rate inhibitor are added.

[0020] Table 1 Performance comparison of a NEPE propellant before and after adding ...

Embodiment 2

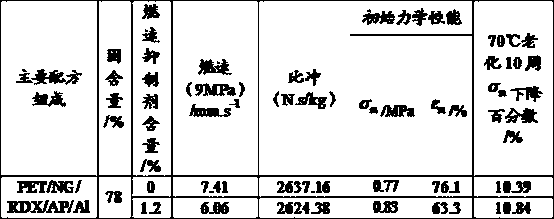

[0023] The static burning rate of the propellant bar added with NEPE propellant burning rate inhibitor, the burning rate test method is the underwater acoustic emission method.

[0024] Table 2 Performance comparison of a NEPE propellant before and after adding burning rate inhibitor

[0025]

Embodiment 3

[0027] The static burning rate of the propellant bar added with NEPE propellant burning rate inhibitor, the burning rate test method is the underwater acoustic emission method.

[0028] Table 3 Performance comparison of a NEPE propellant before and after adding burning rate inhibitor

[0029]

[0030] It can be seen from Tables 1 to 3 that when the burning rate inhibitor is added in the NEPE propellant formula mentioned in this patent to 0.5%~2% of the mass fraction of the propellant formula, it can significantly reduce the propellant combustion rate. speed effect, and because its content is small, it has no obvious impact on the energy performance, mechanical performance and storage performance of the propellant, so the present invention has extremely strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com