Paper raw material pulp smashing device

A technology for equipment and raw materials, applied in the field of paper raw material mashing equipment, can solve the problems of low manual operation efficiency, large manual labor, and inability to meet the output, and achieve the effects of simple structure, large processing volume, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

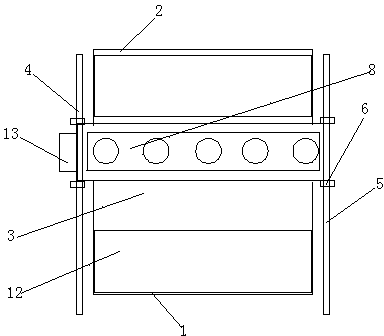

[0015] Example 1, such as figure 1 , 2 As shown, a kind of paper raw material pulping equipment includes a pulping area and a mechanical pulping device, and the pulping area includes a front pulping tank 1, a rear pulping tank 2 and a central stock preparation area 3, in the pulping area A first slideway 4 and a second slideway 5 are arranged on both sides, and a mechanical pulping device is arranged on the first slideway 4 and the second slideway 5 .

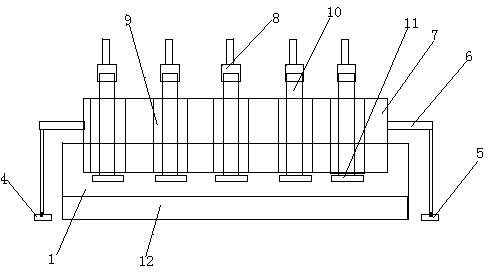

[0016] The mechanical pulping device includes a walking frame 6 arranged on the first slideway 4 and a second slideway 5, an equipment positioning block 7 arranged on the walking frame 6, and a power output arranged on the upper part of the equipment positioning block 7 Walking control motor 13 is also set on equipment 8, walking frame 6.

[0017] The device positioning block 7 is provided with a plurality of through holes 9, and a connecting rod 10 is arranged in the through hole 9, and a mashing block 11 is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com