Horizontal closestool system

A horizontal row toilet and horizontal row technology, applied in flush toilets, water supply devices, buildings, etc., can solve the problems of polluting the surrounding environment, insecurity, and odor return, and achieve the elimination of visual pollution, high engineering quality, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

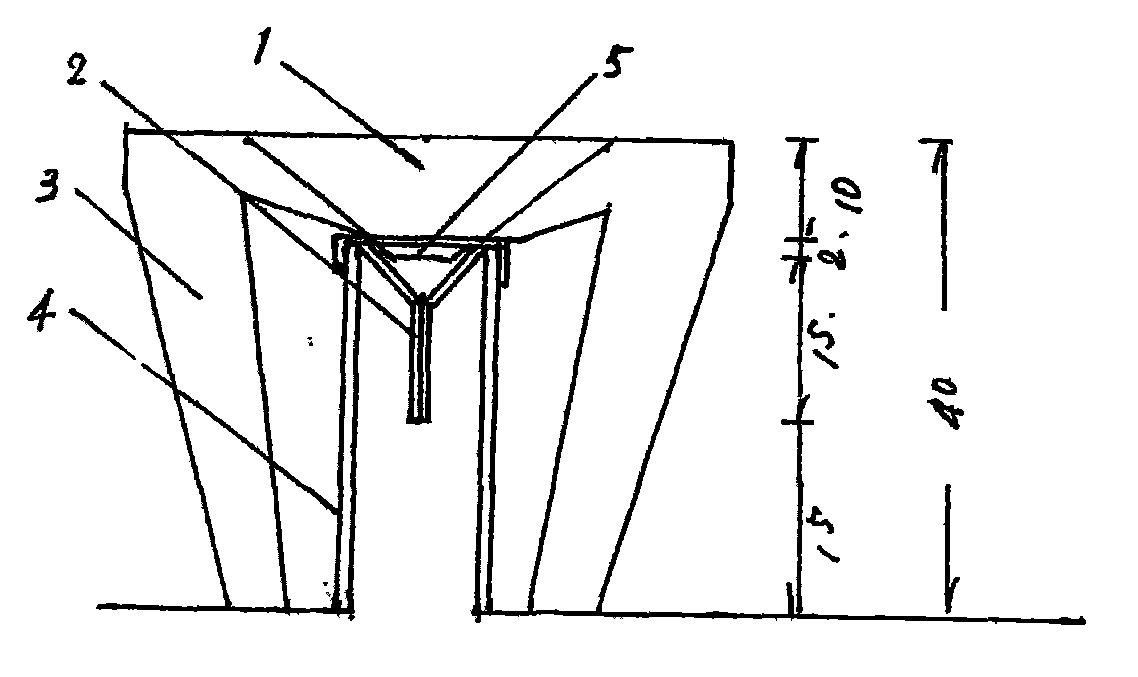

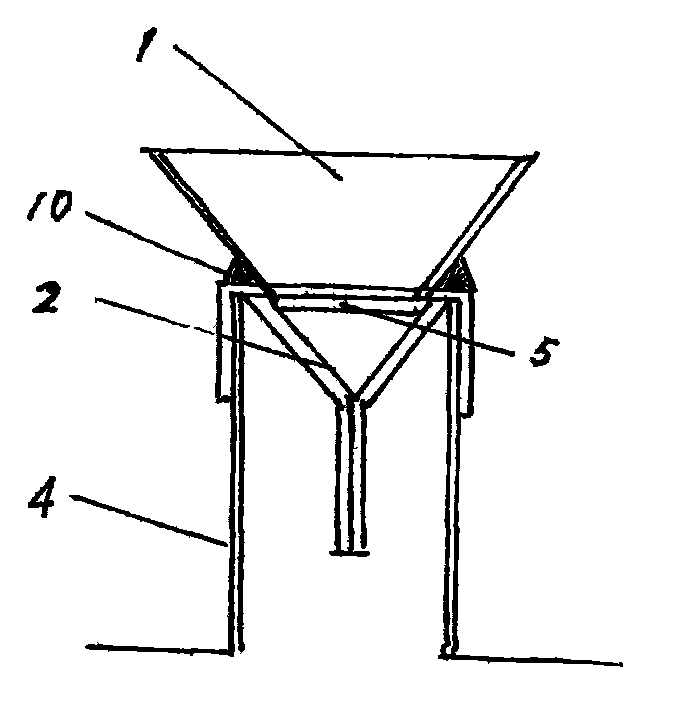

[0044] (1) Horizontal toilet:

[0045] 1. Installation method:

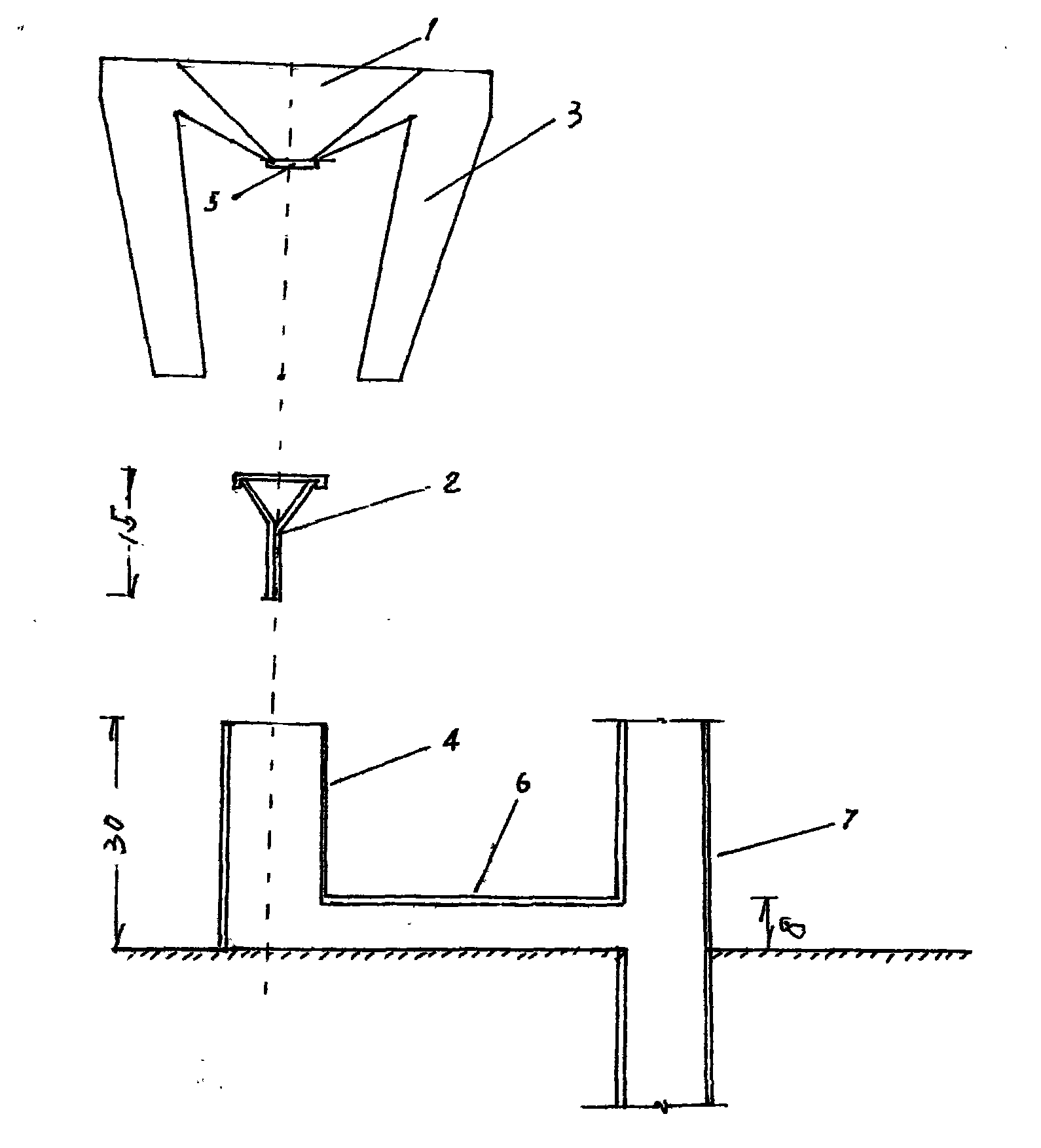

[0046] ( image 3 ) firstly connect the horizontal pipes (6) to the main drainage pipe (7) according to the above-ground type, underground type, or semi-underground type, and then connect the vertical drainage pipe (4) to the horizontal drainage pipe (6) to install the anti-odor Put the automatic cutting (2) in the upper opening of the vertical drainage pipe (4), and then accurately insert the horizontal toilet bowl outlet (5) into the deodorant automatic cutting (2), apply sealant (10) on the socket, That's it.

[0047] 2. How to use:

[0048] When the feces come down, they just fall into the anti-odor automatic valve (2), and the gravity of the instant feces opens the anti-odor automatic valve (2), and is discharged into the vertical drainage pipe (4), and the anti-odor automatic valve is closed immediately, realizing 100% anti-odor Return to odor, there is no feces residue in the toilet, just rinse with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com