Novel regeneration recycle gas aftercooler

A technology of circulating gas and aftercooler, used in chemical industry, cold exchange equipment, and petroleum field, can solve the problems of increased use cost, medium leakage, and short anticorrosion time, so as to reduce industrial use cost, reduce maintenance and replacement, and reduce environmental protection. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate description and understanding of the technical content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

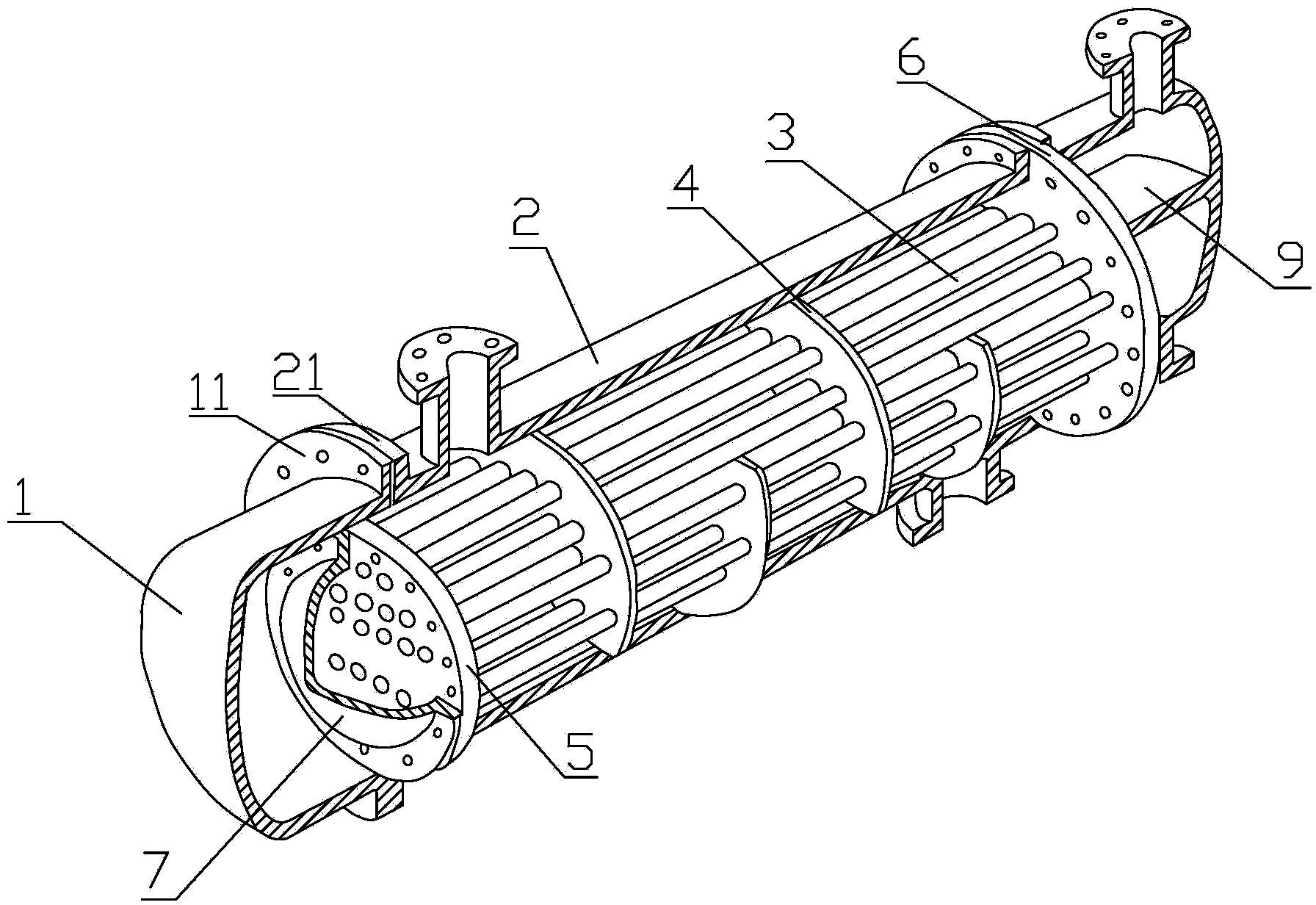

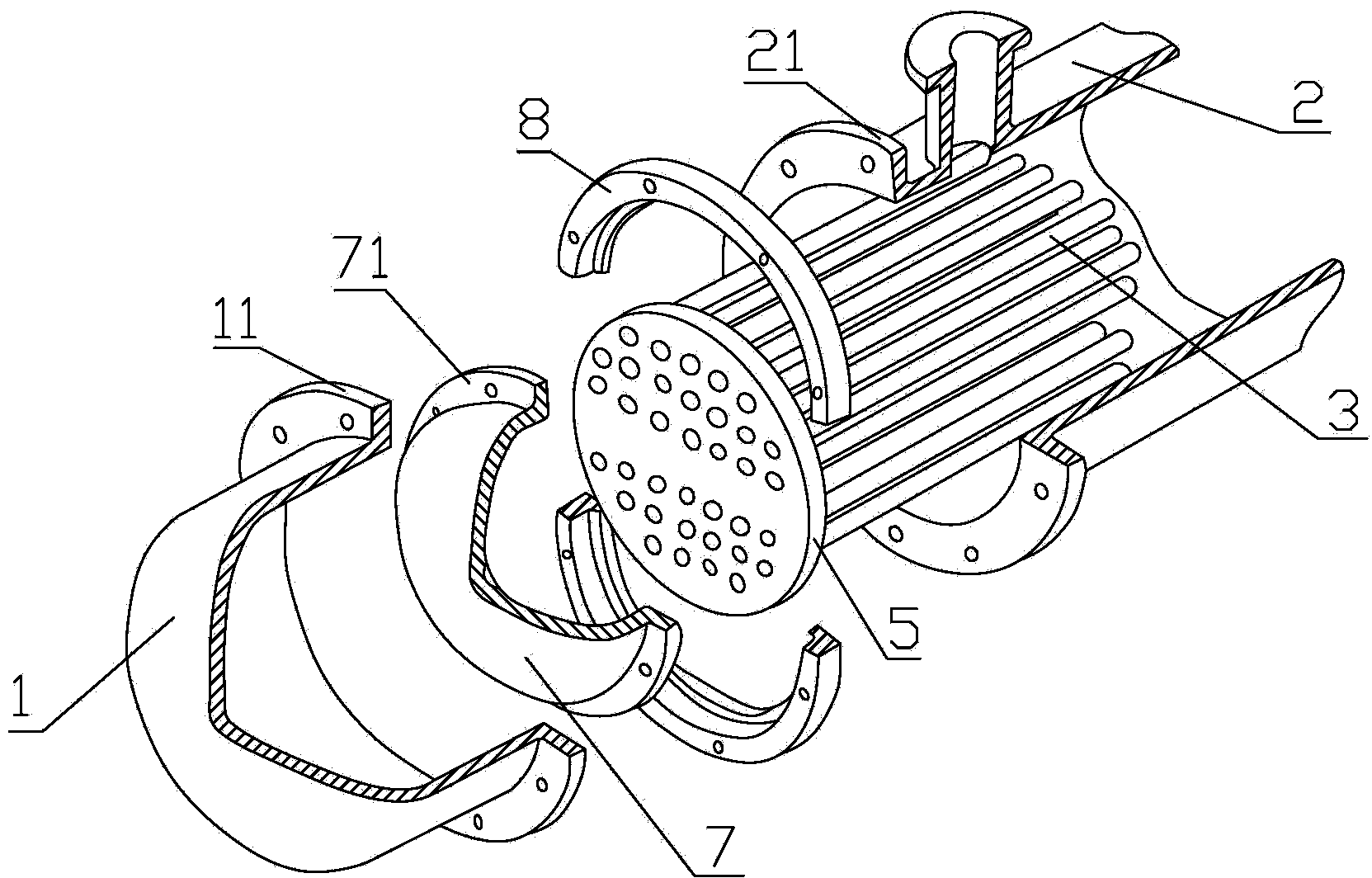

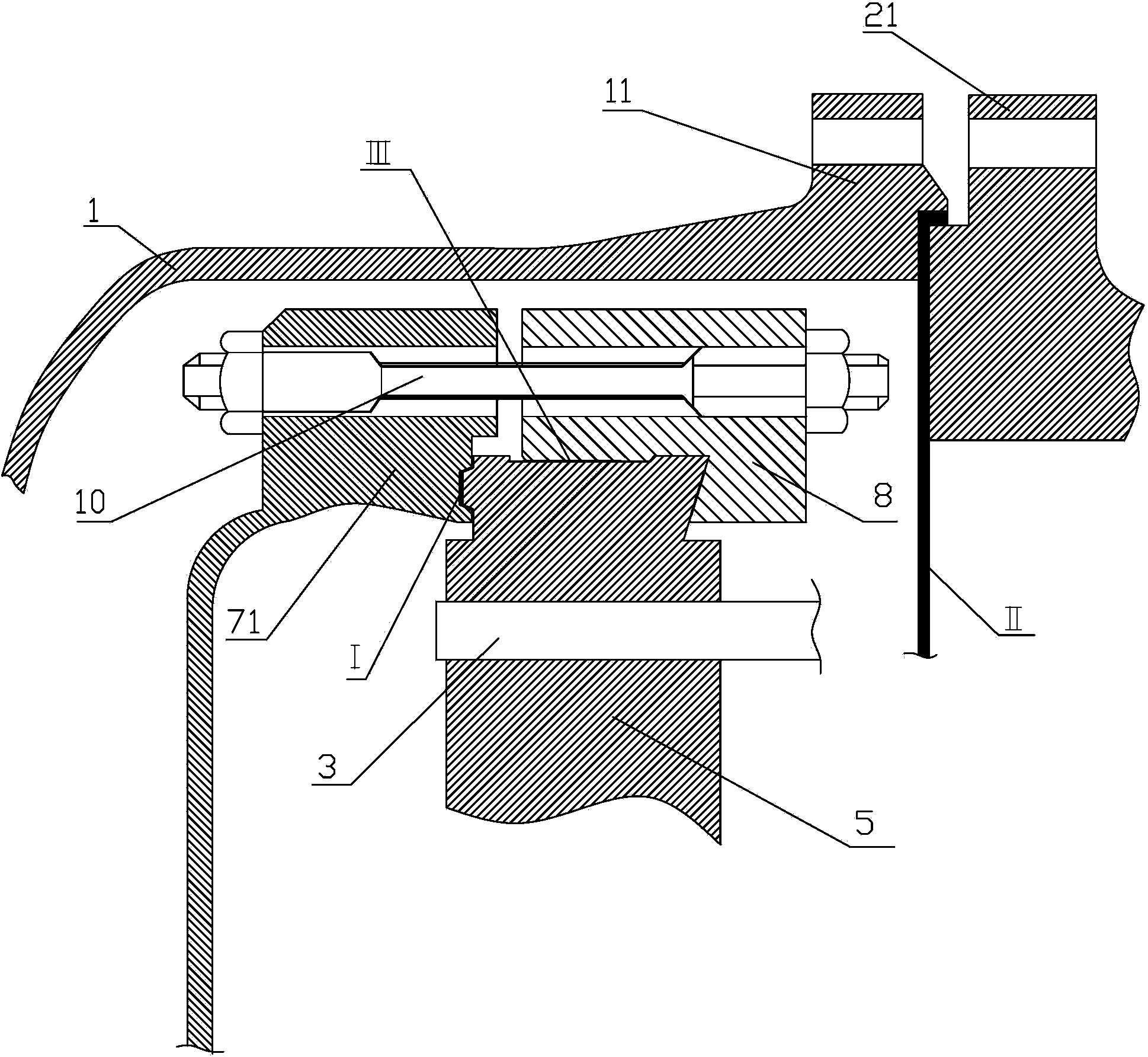

[0027] Such as figure 2 and image 3 The new oil-gas condensing cooler at the top of the fractionating column is shown in the figure 1 The structure of the floating head part is improved on the basis of the above. This new type of regenerative circulating air aftercooler improves the structure of its floating head end, so that the baffle plate 4 is D-shaped (that is, a disc with a part cut off) and the radial length of its incomplete part is 2 one-fifth of the inner diameter. And the incomplete ends of two adjacent baffles 4 are arranged alternately in the vertical direction, that is, the incomplete end of a certain baffle 4 is upward, and the incomplete end of the adjacent baffle 4 is downward, and so on. At the same time, the distance between two adjacent baff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com