Formation method of semiconductor structure

A semiconductor and dry etching technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as leakage current, threshold voltage drift, and influence on integrated circuit performance, and achieve the effect of increasing the etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

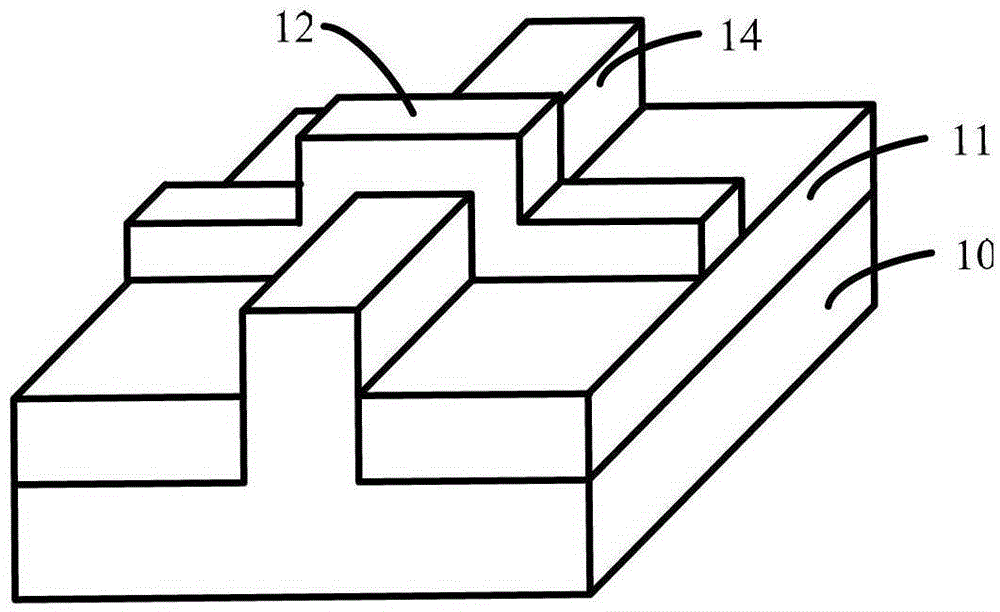

[0032] As mentioned in the background art, there are problems such as leakage current and unstable threshold voltage of fin field effect transistors at present, which affect the performance of transistors and integrated circuits.

[0033] After research, it is found that in the FinFET, the quality of the interface between the gate structure and the fin has a great influence on the performance of the FinFET. The study found that compared with the Si(110) surface, the Si(551) surface is easier to arrange atoms, has fewer surface defects, and has a higher current driving capability. The Si (551) crystal plane is an inclined plane, and the fins with inclined sidewalls are more conducive to the deposition of the gate structure and improve the interface quality. However, in the prior art, most of the fins with inclined sidewalls have complicated process and need to etch the fins multiple times, which is easy to cause damage to the sidewalls of the fins.

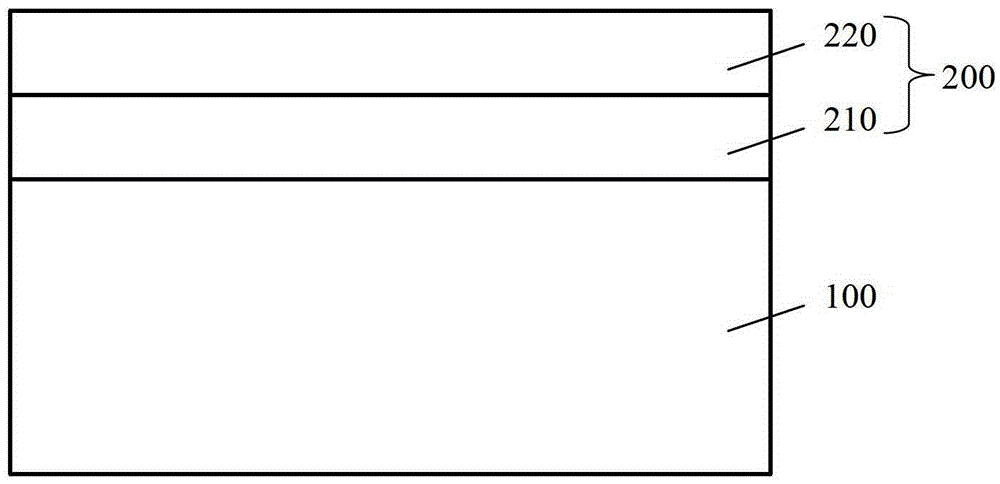

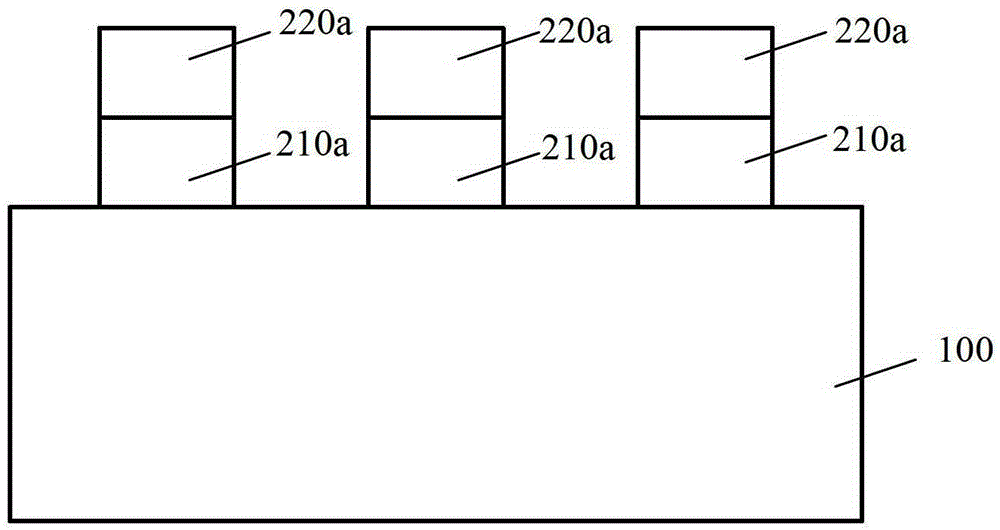

[0034] In order to solve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com