Silver alloy wire for bonding applications

A technology for bonding wires and leads, used in welding equipment, metal processing, welding media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

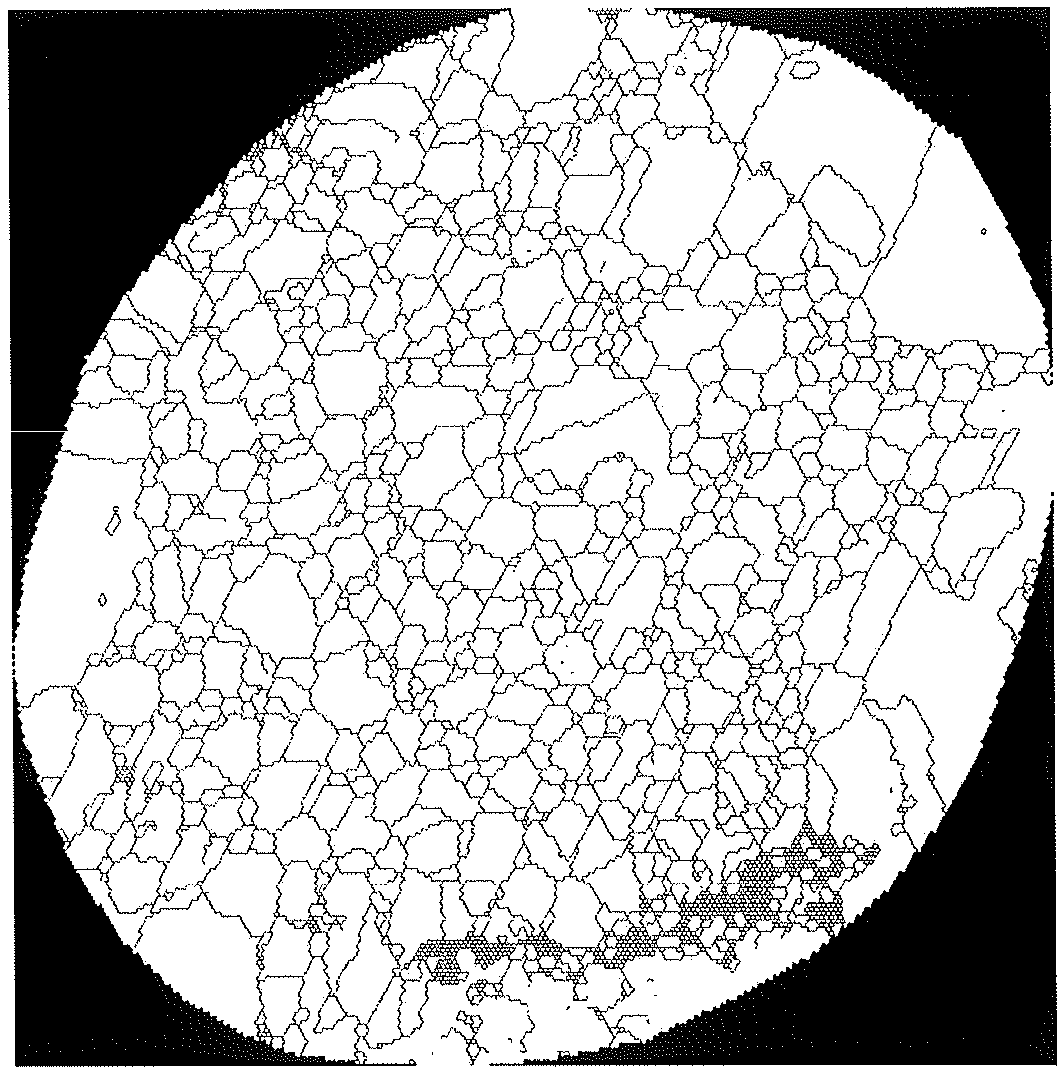

Image

Examples

example

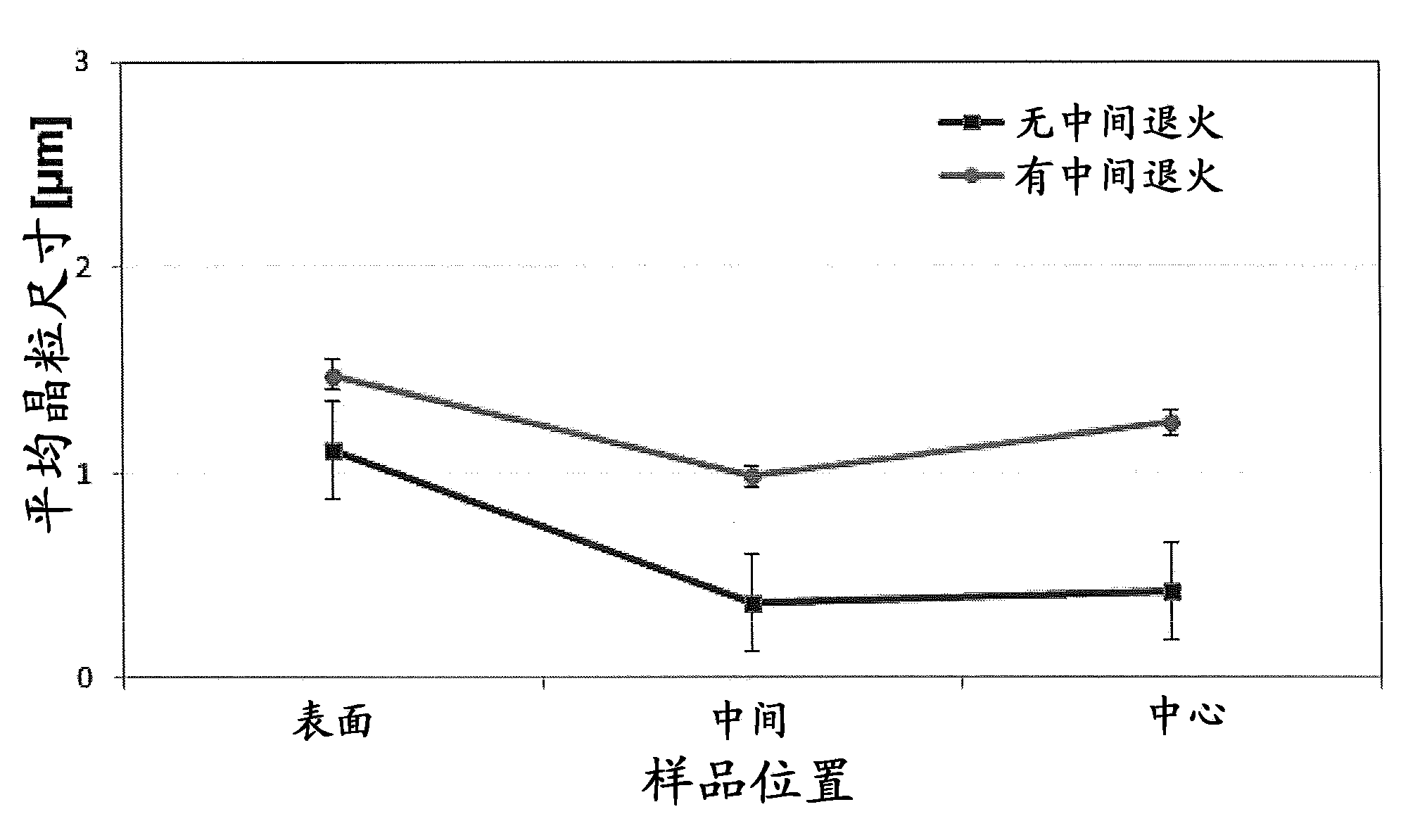

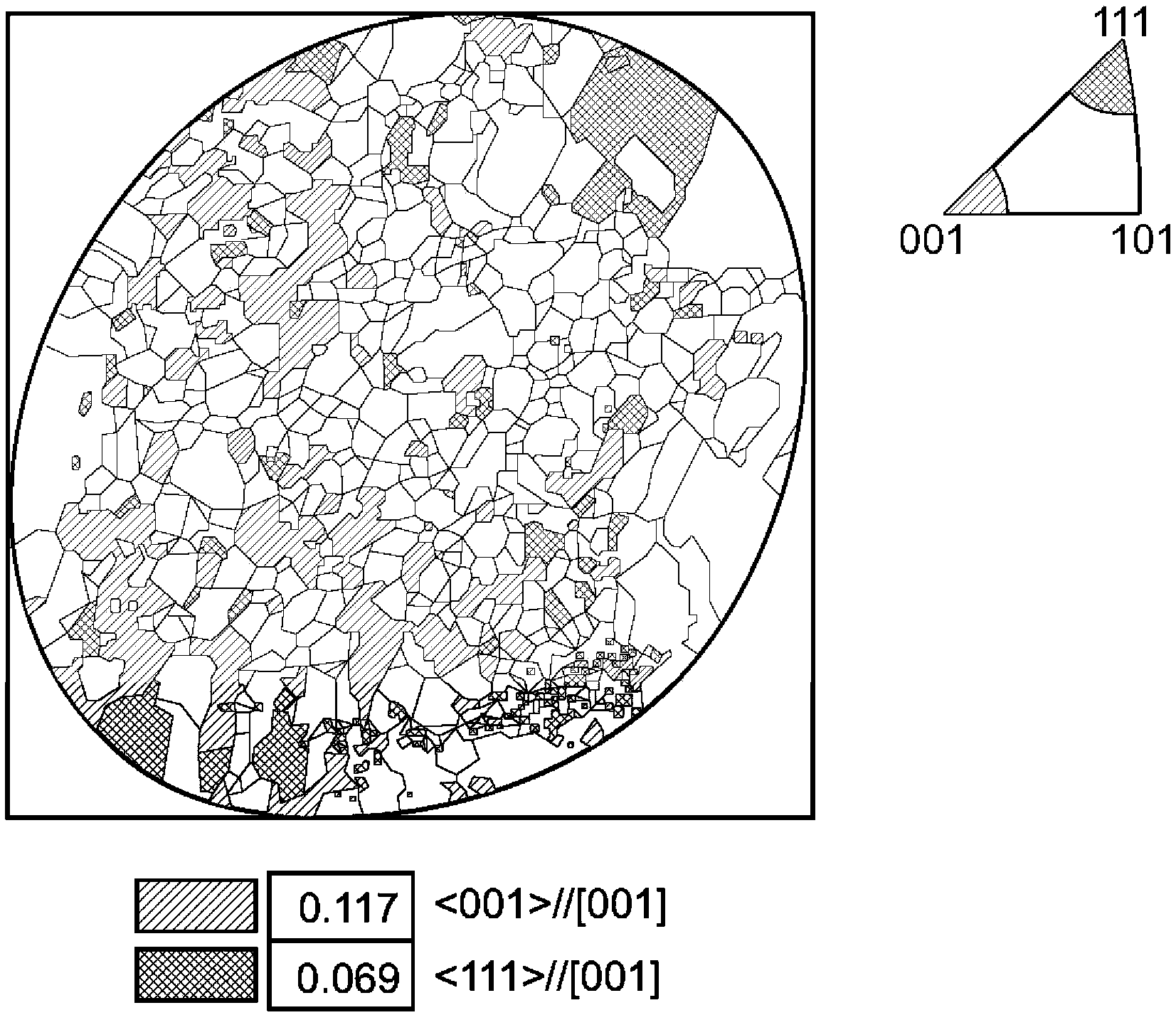

[0072] The invention is further illustrated by examples. This example serves to illustrate the invention and is not intended to limit the scope of the invention or the claims in any way.

[0073] Alloys were prepared by melting predetermined amounts of pure silver and adding predetermined amounts of pure gold and palladium to obtain a well mixed composition as follows (in weight-%):

[0074] silver gold palladium

[0075] 89% 8% 3%

[0076] The molten mixture was cast and cooled to obtain a lead core precursor. The lead precursor had a diameter of 2 mm.

[0077] The 2 mm diameter lead core precursor was then annealed in an intermediate annealing step. In this step, the core precursor is inserted into an annealing furnace preheated to a temperature of 500°C. Then, the core precursor was kept in the furnace at a constant temperature of 500° C. for an exposure time of 90 minutes.

[0078] This intermediate annealing step was followed by a cooling step with the following par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com