Fuel cell low-temperature quick-starting system and method adopting staged temperature control

A fuel cell and temperature control technology, used in fuel cells, fuel cell additives, power system fuel cells, etc., can solve the problems of uneven heating of fuel cell stacks and slow start-up speed of fuel cell stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

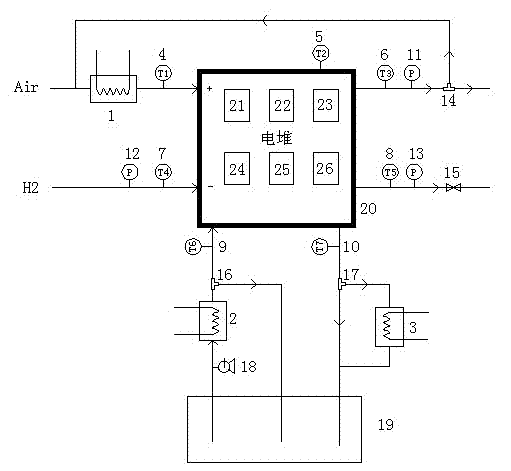

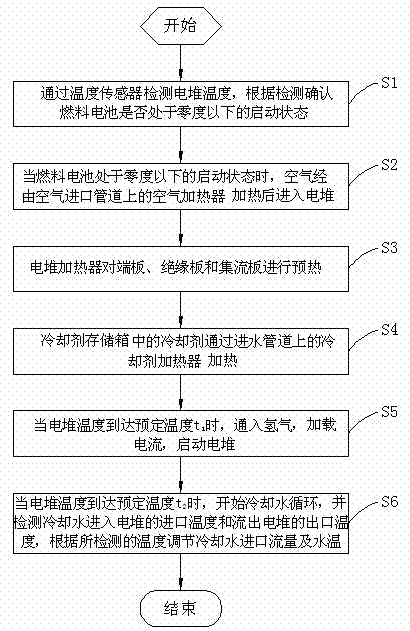

Method used

Image

Examples

Embodiment 1

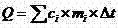

[0066] Example 1 10 KW electric stack cells, 5L of cooling water; 150 30KW electric stack single cells, 15L of cooling water.

[0067] It can be seen from the above table that the temperature of 1kW stack MEA and bipolar plate assembly rises to The heat required is only a small percentage compared to other components. Therefore, the staged heating and temperature control according to the present invention can greatly shorten the heating time and enable rapid loading. End plates, insulating plates and collector plate assemblies, and coolant require much more heat, but they can take longer to heat up. In this way, the graded temperature control can achieve fast and safe start-up, which shows its superiority.

[0068] For a 30kW stack, the temperature of MEA and bipolar plate assembly, end plate assembly and coolant rises to The required heat accounts for 13.7%, 8.4%, and 77.9% of the heat required by the entire system. Therefore, the staged heating and temperature control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com