Method for enhancing power generation efficiency and separating gas, and gas separating system

A technology of gas separation and power generation efficiency, which is applied in the direction of oxygen preparation and single-network parallel feeding arrangement, etc., which can solve the problems of large energy loss, excessive oxygen consumption, loss, etc., and achieve the effect of protecting the power load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

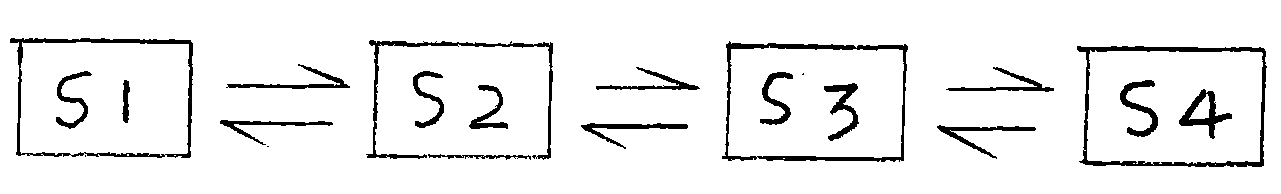

Method used

Image

Examples

specific Embodiment 1

[0036] Specific embodiment 1, comprise generator set and gas separation unit, gas separation device is an oxygen generator unit, and oxygen generator is oxygen and nitrogen oxygen generator, is respectively the 110,000 cubic meters / h system that power load is at least 40,700 kw Oxygen units, 150,000 cubic meters / h oxygen generators with a power load of at least 55,500 kw, 50,000 cubic meters / h oxygen generators with a power load of about 22,000 kw, and power loads of about 4,300 kw 10,000 cubic meters / h oxygen generating unit; the oxygen generating unit includes main engine and auxiliary machine; the oxygen generating unit has its own control department, power dispatching department and sensor department, and the sensor department, control department and power dispatching department are respectively connected by wired and wireless , the gas separation device has public oxygen and nitrogen storage tanks, the oxygen production process of the 50,000 m3 / h oxygen generator unit and ...

specific Embodiment 2

[0037] Specific embodiment 2, including generator set and gas separation unit, gas separation device is an oxygen generator unit, oxygen generator is oxygen, nitrogen and argon oxygen generator, and gas separation device oxygen generator unit is respectively 4500 cubic meters / h film legal system Oxygen units, 110,000 cubic meters / h oxygen generators have a power load of at least 40,700 kw, 150,000 cubic meters / h oxygen generators have a power load of at least 55,500 kw, and 50,000 cubic meters / h oxygen generators The power load of the oxygen generator is about 22,000 kw, and the power load of the 10,000 cubic meters / h oxygen generator is about 4,300 kw; Ministry of Information and Communication / Electric Power Dispatch are connected through wired and wireless respectively. The gas separation device has public oxygen, or argon, or nitrogen storage tanks, 50,000 cubic meters / h oxygen generator and 10,000 cubic meters / h The oxygen production process of the oxygen production unit i...

specific Embodiment 3

[0038]Specific embodiment 3, the power plant has one or more generating sets, and the generating sets all operate at the economical operating power; the generating capacity exceeding the power grid dispatching permission is used to run a corresponding number of gas separation devices, and the gas separation device is an oxygen generating unit. Oxygen machines are oxygen and nitrogen oxygen generators, and the oxygen generators are 110,000 cubic meters / h, and the electricity load of the oxygen generators is at least 40,700 kw, and the electricity load of the 150,000 cubic meters / h oxygen generators is at least 5.55 The electricity load of 10,000 kw and 50,000 cubic meters / h oxygen generator is about 22,000 kw, the electricity load of 4,500 cubic meters / h membrane oxygen generator and 10,000 cubic meters / h oxygen generator is about 4,300 kw , the 10,000 m3 / h oxygen generator is an adsorption oxygen generator; the oxygen generator includes a main engine and an auxiliary engine; ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com