Processing method of shellfish solid drinks

A processing method and solid beverage technology, applied in the fields of marine biotechnology and food processing, can solve the problems of unpleasant yeast taste of fermentation liquid, strict industrial production requirements, increased shellfish pollution and corruption, etc. There is no wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

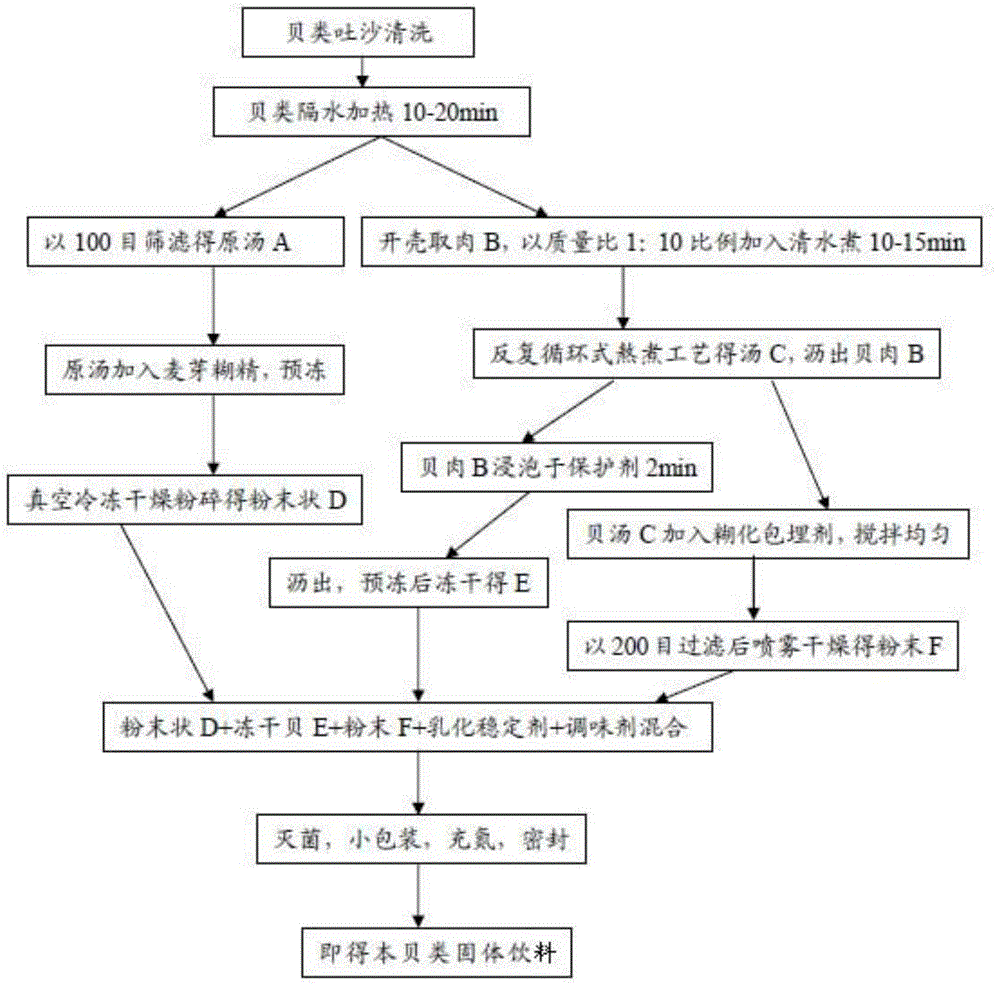

Image

Examples

Embodiment approach 1

[0023] Embodiment 1: The processing method of the shellfish (Hongdao clam) solid beverage comprises the following steps,

[0024] Step (1) - pre-treatment of raw materials in sections: take fresh red island clams, after desanding and cleaning, steam them, and filter out shellfish soup A with a 100-mesh filter; shell the remaining steamed shellfish and take shellfish meat , divide the shellfish into 3 to 5 batches, first add clear water to the first batch of shellfish with a mass ratio of 1:10, cook for 10 to 15 minutes, drain shellfish B; then add to the obtained boiled soup Continue to cook the second batch of steamed shellfish; adopt such a repeated cycle of cooking, and change the water every time 3 to 5 batches of shellfish are cooked, and get shellfish soup C;

[0025] Step (2) - Vacuum freeze-drying of the original soup: add 10-50% maltodextrin to the filtered original soup A in step (1), stir to dissolve, put it in -60°C for pre-freezing, and freeze-dry it to freeze-dry...

Embodiment approach 2

[0029] Embodiment 2: The processing method of the shellfish (Hongdao clam) solid beverage comprises the following steps,

[0030] Step (1) - pre-treatment of raw materials in sections: take fresh red island clams, after desanding and cleaning, steam them, and filter out shellfish soup A with a 100-mesh filter; shell the remaining steamed shellfish and take shellfish meat , divide the shellfish into 3 to 5 batches, first add clear water to the first batch of shellfish with a mass ratio of 1:10, cook for 10 to 15 minutes, drain shellfish B; then add to the obtained boiled soup Continue to cook the second batch of steamed shellfish; adopt such a repeated cycle of cooking, and change the water every time 3 to 5 batches of shellfish are cooked, and get shellfish soup C;

[0031] Step (2) - Vacuum freeze-drying of the original soup: add 10-50% maltodextrin to the filtered original soup A in step (1), stir to dissolve, put it in -60°C for pre-freezing, and freeze-dry it to freeze-dry...

Embodiment approach 3

[0035] Embodiment 3: The processing method of the shellfish (scallop) solid beverage comprises the following steps,

[0036] Step (1)—Pre-treatment of raw materials in sections: take fresh scallops, desand and wash them, steam them, and filter out shellfish soup A with a 100-mesh filter; shell the remaining steamed shellfish and take shellfish meat, The shellfish meat is divided into 3 to 5 batches. First, water is added to the first batch of shellfish meat with a mass ratio of 1:10, boiled for 10 to 15 minutes, and the shellfish meat B is drained; then the second batch of shellfish meat is added to the obtained boiling soup. Batch-steamed scallops continue to cook; adopt such a repeated cycle of cooking, and change the water every 3 to 5 batches of scallops to get shellfish soup C;

[0037] Step (2) - Vacuum freeze-drying of the original soup: add 10-50% maltodextrin to the filtered original soup A in step (1), stir to dissolve, put it in -60°C for pre-freezing, and freeze-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com