High-tenacity vacuum slow epoxy resin for wind power blade and preparation method thereof

A technology of epoxy resin and wind turbine blades, which is applied in the field of vacuum slow epoxy resin and its preparation, can solve the problems of poor bonding performance and low strength of cured products, and achieve improved impact performance, simple preparation method, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

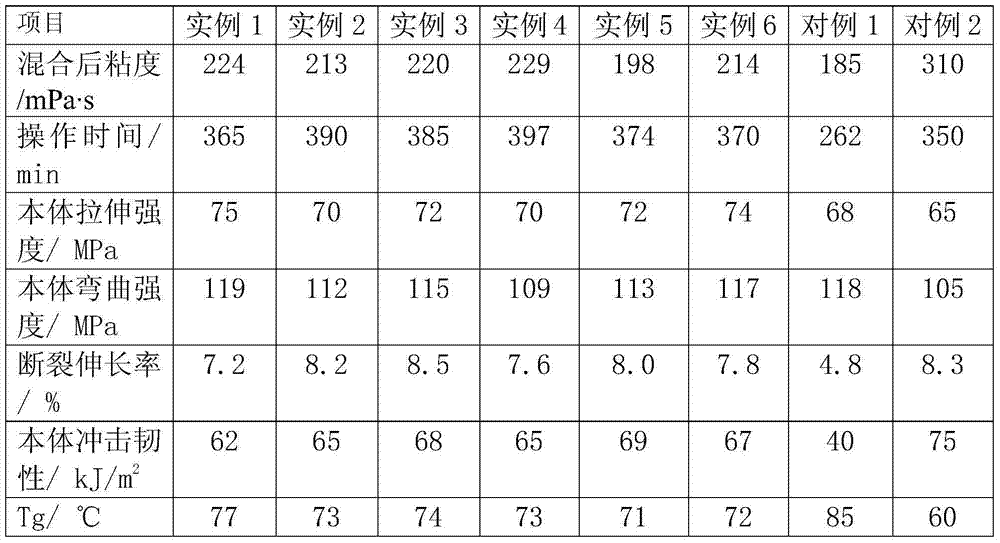

Examples

Embodiment 1

[0022] A method for preparing a high-toughness vacuum slow-speed epoxy resin for wind power blades, comprising the following steps:

[0023] (1) Preparation of component A

[0024] 72 parts by weight of bisphenol A epoxy resin, 2 parts by weight of monovinyl-terminated epoxy polyether (epoxy value 0.1), 10 parts by weight of bisvinyl-terminated epoxy polyether (epoxy value 0.125), D Put 14 parts by weight of glycidyl ether, 0.5 parts by weight of silane coupling agent, and 1.5 parts by weight of BYK-555 into the reaction kettle, heat to 50-80°C, stir at a stirring speed of 400-550r / min for 1.5-2h, and vacuumize Stop stirring after 30-60 minutes, continue vacuuming for 5-30 minutes, cool down, and put the resin into packaging barrel 1;

[0025] (2) Preparation of component B

[0026] Put 23 parts by weight of polyetheramine and 10 parts by weight of triethylenetetramine into the reactor, heat to 40-65°C, stir at a stirring speed of 450-550r / min for 1.5-2h, vacuumize for 30-60...

Embodiment 2

[0029] The preparation method of components A and B of the vacuum slow epoxy resin of this embodiment is the same as that of Example 1, wherein the formula of component A is as follows: 69 parts by weight of bisphenol F epoxy resin, monovinyl terminated epoxy resin 3 parts by weight of polyether (epoxy value 0.125), 10 parts by weight of divinyl-terminated epoxy polyether (0.125 epoxy value), 8.5 parts by weight of neopentyl glycol glycidyl ether, 7 parts by weight of butyl glycidyl ether , 1.0 parts by weight of silane coupling agent, 1.5 parts by weight of BYK-515; the formula of component B is 18 parts by weight of polyetheramine, and 10 parts by weight of m-phenylenediamine.

[0030] Mix A and B components at a ratio of 100:28 (parts by weight), stir at room temperature for 40 minutes, and mix well. The uniformly mixed resin can be cured at room temperature according to the mold used, and then cured at 70°C for 10-12 hours to obtain the cured finished product.

Embodiment 3

[0032]The preparation method of component A and component B of the vacuum slow epoxy resin of the present embodiment is the same as that of Example 1, wherein the formula of component A is as follows: 60.5 parts by weight of bisphenol A epoxy resin, bisphenol F epoxy resin 10 parts by weight of resin, 9 parts by weight of monovinyl-terminated epoxy polyether (epoxy value 0.15), 9 parts by weight of divinyl-terminated epoxy polyether (epoxy value 0.125), 3 parts by weight of aryl glycidyl ether Parts, 5 parts by weight of butyl glycidyl ether, 2 parts by weight of neopentyl glycol glycidyl ether, 0.5 parts by weight of silane coupling agent, 1.0 parts by weight of BYK-515; the formula of component B is 15 parts by weight of polyetheramine, three 10 parts by weight of ethylene tetramine, 5 parts by weight of tetraethylene pentamine.

[0033] Mix A and B at a ratio of 100:30 (parts by weight), stir at room temperature for 40 minutes, and mix well. The uniformly mixed resin can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com