Manufacturing method of coating on the surface of cylinder head gasket

A production method and a technology of a cylinder head gasket, applied in coating, printing device, printing, etc., can solve the problems of coating bubble coating, uneven coating, poor bonding of coating and metal plate, etc., and achieve the elimination of bubbles, Better effect, better bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

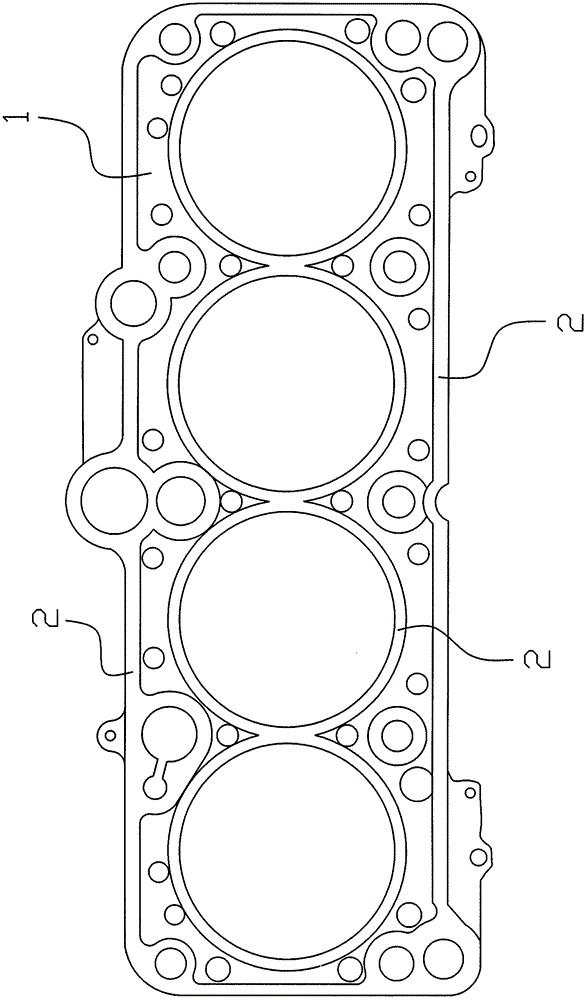

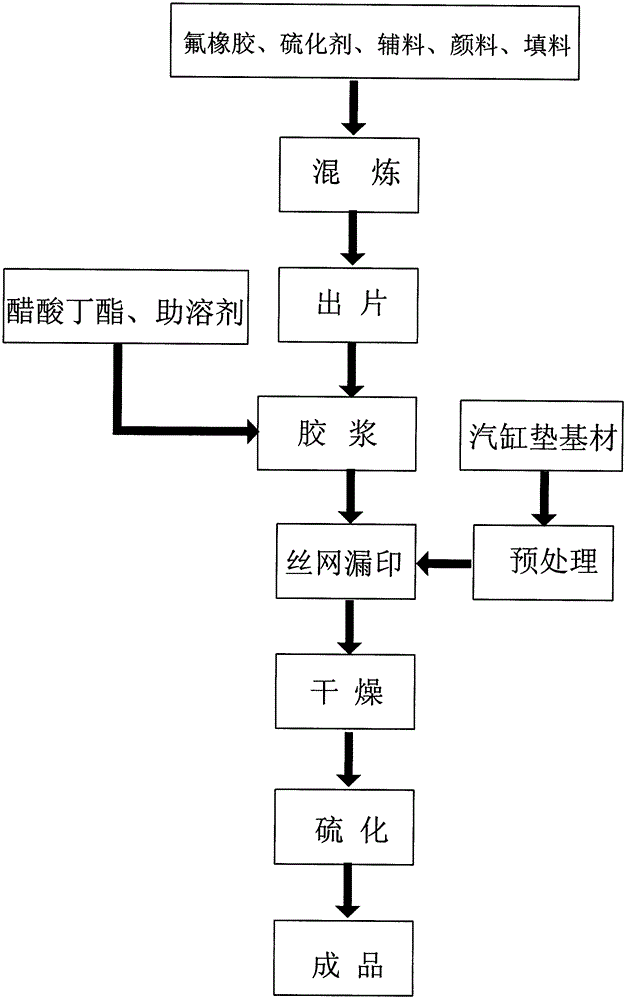

[0024] Such as figure 1 with figure 2 Shown, the coating on the surface of the cylinder gasket of the present embodiment, its formula consists of:

[0025] 78-85 parts of fluorine rubber, 15-25 parts of reinforcing agent, 8-15 parts of active magnesium oxide, 2-6 parts of vulcanizing agent, 4-8 parts of calcium hydroxide, 1-10 parts of pigment, the reinforcing agent can be The choices are: carbon black or diatomaceous earth. Of course, 1 to 5 parts of fluorine defoaming agent and 1 to 5 parts of fluorine leveling agent can also be added to the formula, and the above are parts by weight. The pigment can be determined according to the required requirements, such as molybdenum disulfide or phthalocyanine blue, etc. can be selected.

[0026] The preparation method of coating of the present invention comprises the following steps:

[0027] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com