A ground treatment method

A technology for foundation treatment and construction method, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as unsatisfactory effect, long construction period, difficult implementation, etc., and achieve easy control of construction quality, continuous soil treatment, and use wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

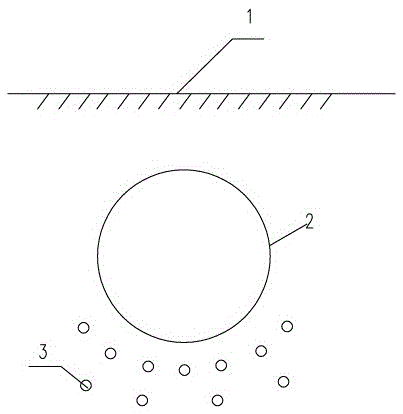

[0025] Embodiment 1: as figure 1 As shown, the directional drilling along the project direction and the formation of tunnels in the present invention refer to the directional drilling parallel to the project direction in the linear engineering (such as underground buildings such as subway tunnels) along the direction of the project direction. The construction method of forming the tunnel.

[0026] The specific implementation steps are: divide the section to be reinforced into one or several working sections along the direction of the tunnel, carry out directional drilling along the project direction in each working section, and lay grouting pipes 3 in the formed tunnels, according to the design requirements Perform soil grouting. For the soil treatment under underground buildings (structures) such as (subway) tunnels 2, it can be carried out before the project construction starts, or it can be carried out during the project use stage according to the needs, and the imple...

Embodiment 2

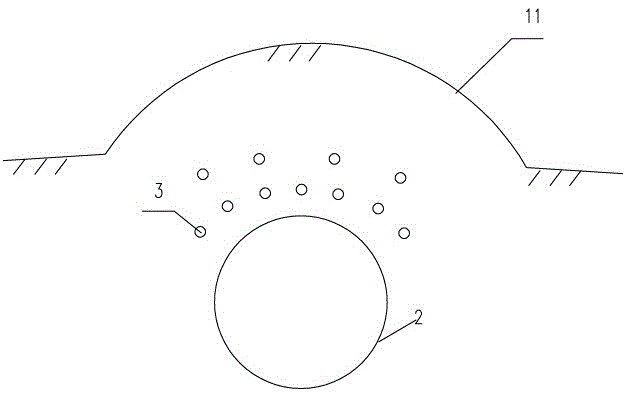

[0027] Embodiment 2: as figure 2 As shown, the directional drilling along the project direction and the formation of tunnels in the present invention refer to the construction of directional drilling parallel to the project direction and forming tunnels above the project direction in linear projects (such as mountain tunnels) method.

[0028] According to the steps described in the above-mentioned embodiment 1, the soil is treated before the excavation of the mountain tunnel, so as to achieve the effect of strengthening the soil and waterproofing, and effectively prevent the cave roof from collapsing when the tunnel is excavated. It avoids the problems of conventional tunnel excavation while supporting and excavating, which is a waste of time and has high risks. It can also realize the reinforcement of the tunnel roof under the condition of uninterrupted use of the tunnel, which is impossible with conventional tunnel reinforcement technology.

Embodiment 3

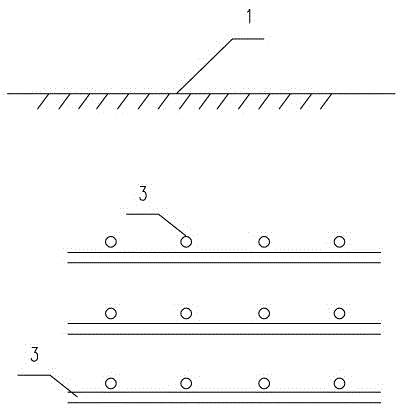

[0029] Embodiment 3: as image 3 , 4 As shown, the directional drilling along the project direction and the formation of tunnels in the present invention refer to the multi-directional directional drilling parallel to the project direction carried out in the planar engineering (such as airports, dams, etc.) below the project direction. The construction method of holes and forming tunnels.

[0030] For planar projects such as airports, according to the steps described in the above-mentioned embodiment 1, the linear project foundation treatment method is applied in two directions, and a sufficient number of unidirectional drilling, pipe laying, and grouting can also be carried out according to the width of the project surface.

[0031] For projects such as dams, according to the steps described in the above-mentioned embodiment 1, directional drilling, pipe layout, and grouting in the dam can not only strengthen the strength of the dam itself, but also improve the imperm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com