Method for measuring glycerinum and 1,2-propylene glycol in cigarettes, electronic cigarettes and low-temperature cigarettes

A technology of low-temperature cigarettes and determination methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low moisture-retaining components, etc., and achieve the effects of simple operation, perfect industry standards, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The cigarettes used are flue-cured cigarettes. Take one cigarette sample each, and balance it under the conditions specified in GB / T 16447. Select the cigarettes with an average weight of ±0.02 g and an average draw resistance of ±49 Pa as the sample cigarettes. In YC / T 29 Smoking was carried out with a linear smoking machine under specified conditions, and 44 mm Cambridge filter discs were used to collect the total particulate matter of 4 cigarettes per filter disc. After suctioning, take out the filter piece and put it into a 100 mL Erlenmeyer flask; add 40 mL ethanol solution containing internal standard (1,3-butanediol) for ultrasonic extraction for 30 min, and filter the extract with a 0.45 μm microporous membrane. For instrumental analysis. Simultaneously, the standard recovery experiment was carried out.

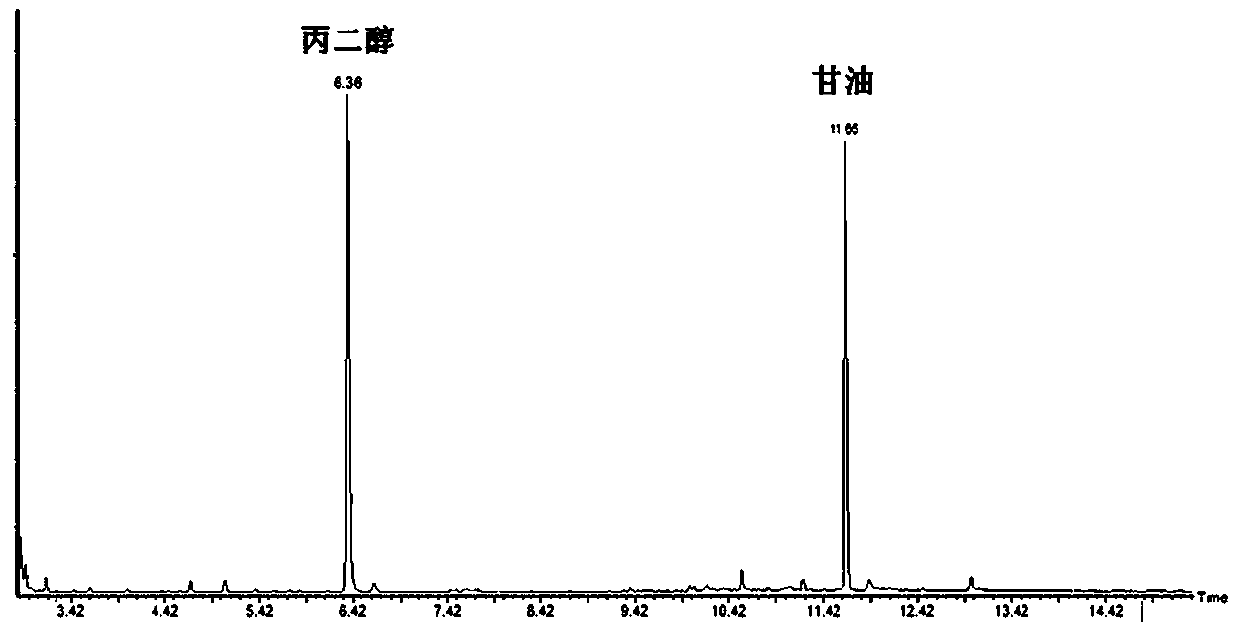

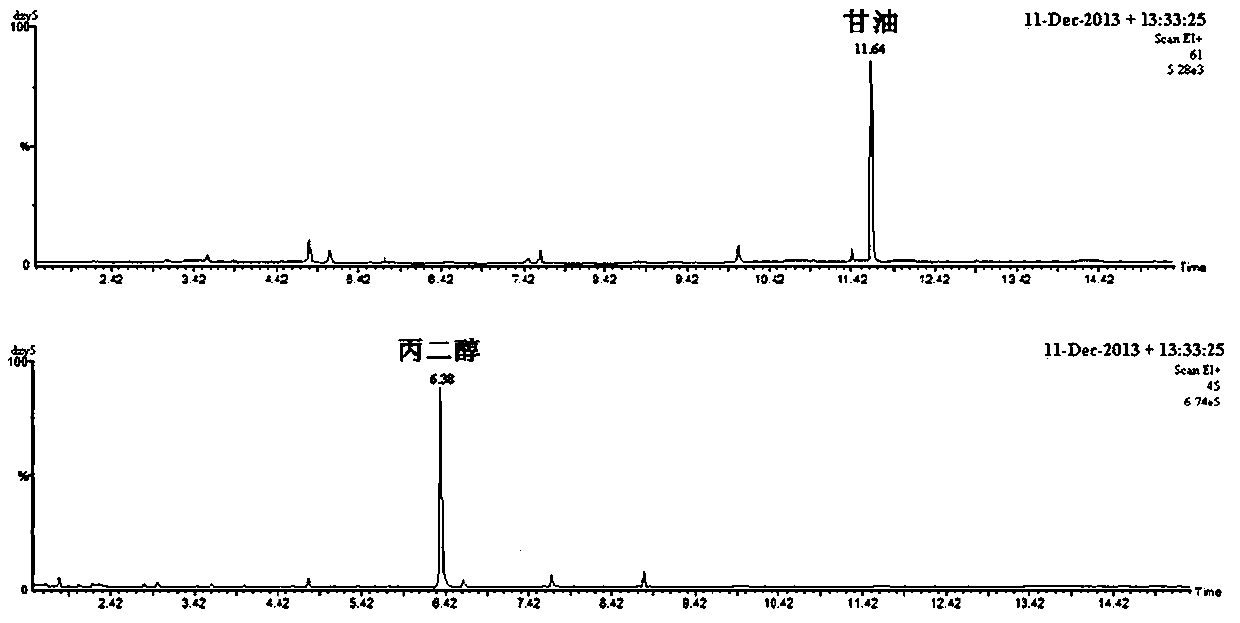

[0040] The analysis conditions of gas chromatography-mass spectrometry were: HP-Inno WAX strong polar capillary column (30 m × 250 μm i.d. × 0. 25 μm d.f.). I...

Embodiment 2

[0043] The cigarettes used are e-cigarettes, and the conditions stipulated by the Canadian deep smoking model are used; the smoke is smoked with a linear smoking machine, and the smoke is collected with a 44 mm Cambridge filter, and each filter collects the total particle phase of 4 cigarettes things. After suctioning, take out the filter piece and put it into a 100 mL Erlenmeyer flask; add 40 mL ethanol solution containing internal standard (1,3-butanediol) for ultrasonic extraction for 30 min, and filter the extract with a 0.45 μm microporous membrane. For instrumental analysis. Simultaneously, the standard recovery experiment was carried out.

[0044] The gas chromatographic analysis conditions were as follows: HP-Inno WAX strong polar capillary column (30 m × 250 mu m i.d. × 0. 25 mu m d.f.). The injection port temperature was 250 °C; temperature program: 110 °C (hold 1 min), 5 °C / min to 200 °C (3 min), then 30 °C / min to 230 °C (3 min). A hydrogen flame detector was...

Embodiment 3

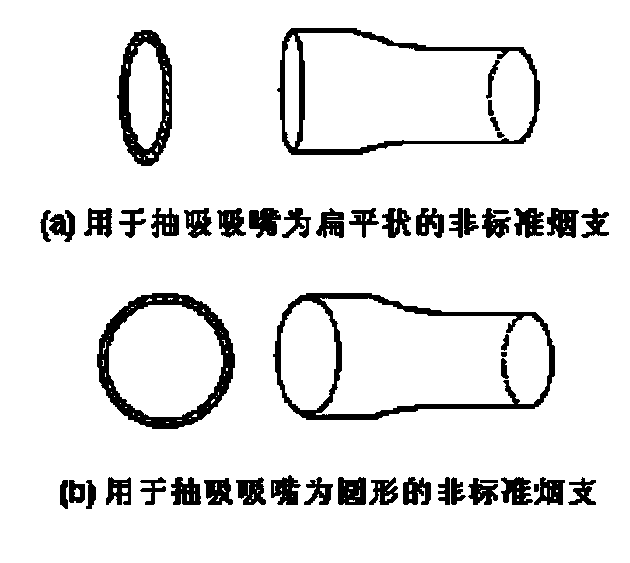

[0047] The cigarettes used are low-temperature cigarettes, and the conditions stipulated by the Canadian deep smoking model are adopted; the smoke is smoked with a linear smoking machine, and the smoke is collected with a 44 mm Cambridge filter, and each filter collects the total particle phase of 4 cigarettes things. After suctioning, take out the filter piece and put it into a 100 mL Erlenmeyer flask; add 40 mL and use ethanol solution containing internal standard (1,3-butanediol) for ultrasonic extraction for 30 min, and filter the extract with a 0.45 μm microporous membrane , for instrumental analysis. Simultaneously, the standard recovery experiment was carried out.

[0048] The analysis conditions of gas chromatography-mass spectrometry were: HP-Inno WAX strong polar capillary column (30 m × 250 μm i.d. × 0. 25 μm d.f.). Injection port temperature 250 °C; temperature program: 110 °C (hold for 1 min), rise to 200 °C at 5 °C / min (hold for 3 min), then rise to 230 °C at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com