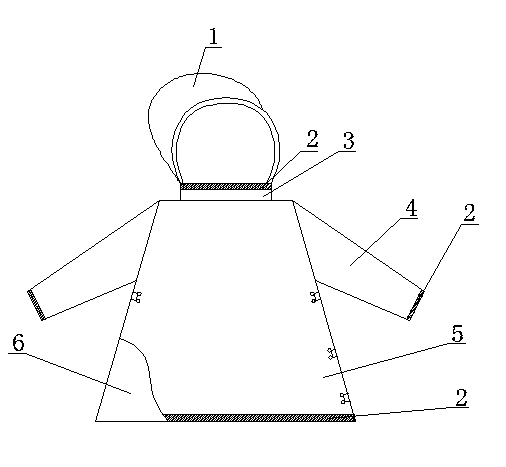

Omni-directional protection type CT (computed tomography) protective garment

A technology of protective and protective clothing, applied in the field of all-round protective CT protective clothing, which can solve the problems of heavy weight, patient damage, injury, etc., and achieve the effect of highlighting substantive features, easy to wear, and easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

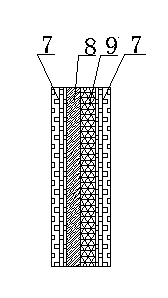

[0019] Select 40 parts of copper-lead alloy, 30 parts of aluminum-lead alloy, 15 parts of tungsten, 15 parts of bismuth, and 15 parts of rare earth as the spraying material, and select 40 parts of bamboo charcoal fiber as the carrier material, that is, the base fiber. The base fiber enters from one end of the plasma spraying furnace, and the other end is horizontally arranged, the fiber passes through the vacuum furnace at a constant speed and the above-mentioned spraying material is placed on the electrode of the furnace cavity, and the spraying material is sprayed under the action of a magnetic field Metal fibers made onto a carrier material. Finally, the warp and weft interweaving of metal fibers is made into a radiation-proof layer.

Embodiment 2

[0021] 70 parts of copper-lead alloy, 50 parts of copper-lead alloy, 25 parts of tungsten, 25 parts of bismuth, and 25 parts of dilute are selected as the spraying material, and 60 parts of hemp fiber are selected as the carrier material, that is, the base fiber. The above method is also used to prepare metal fibers, and finally the metal fibers are interwoven in warp and weft to form a radiation protection layer.

Embodiment 3

[0023] Select 55 parts of copper-lead alloy, 40 parts of copper-lead alloy, 20 parts of tungsten, 20 parts of bismuth, and 20 parts of dilute as the spraying material, and select 50 parts of bamboo charcoal fiber and hemp fiber as the carrier material, that is, the base fiber. The above method is also used to prepare metal fibers, and finally the metal fibers are interwoven in warp and weft to form a radiation protection layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com